Negative electrode of lithium battery for inhibiting growth of lithium dendrites with ZIF-8 porous carbon material

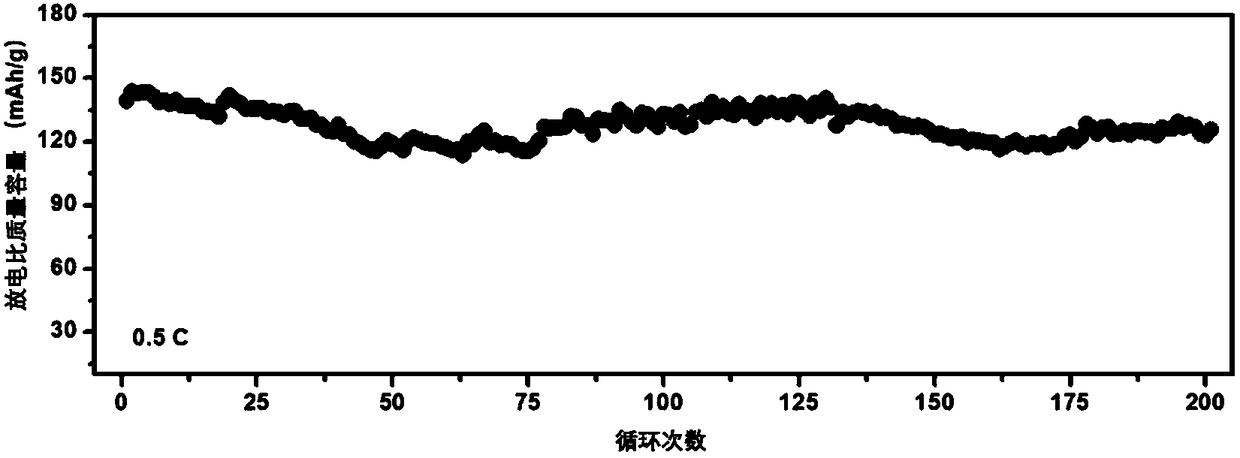

A ZIF-8, porous carbon material technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problems of high cost and complex preparation methods, achieve growth inhibition, improve cycle performance, high ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A lithium battery negative electrode utilizing a ZIF-8 porous carbon material to suppress the growth of lithium dendrites, comprising the following steps:

[0028] (1) Under the condition of magnetic stirring, 7.71g metal nitrate Zn(NO 3 ) 2 ·6H 2 O was dissolved in 750ml of anhydrous methanol to form a colorless and clear solution A; 9.84g of organic ligand 2-methylimidazole was dissolved in the above solution to form a clear solution B, and the clear solution B continued to be magnetically stirred until it became turbid to form an emulsion. The prepared emulsion was aged for 24 h, centrifuged at 6000 rad / min and washed 3 times to obtain a white paste. The prepared white paste was dried in a blast dryer at 60°C for 8 hours, and dried in a vacuum oven at 105°C for 6 hours to obtain a ZIF-8 zeolite imidazolate skeleton;

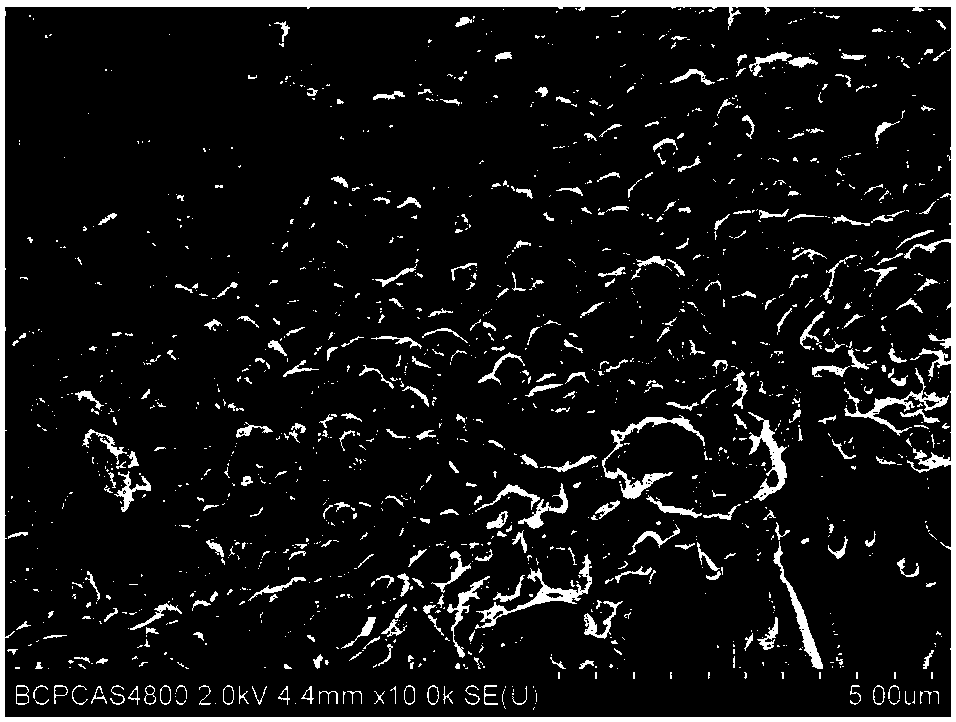

[0029] (2) Grind the dried ZIF-8 material in an agate mortar for 30 min, and keep it in a tube furnace with a nitrogen atmosphere at 900 °C for 5 h ...

Embodiment 2

[0036] A lithium battery negative electrode utilizing a ZIF-8 porous carbon material to suppress the growth of lithium dendrites, comprising the following steps:

[0037] (1) Under the condition of magnetic stirring, 7.71g metal nitrate Zn(NO 3 ) 2 ·6H 2 O was dissolved in 750ml of anhydrous methanol to form a colorless and clear solution A; 9.84g of organic ligand 2-methylimidazole was dissolved in the above solution to form a clear solution B, and the clear solution B continued to be magnetically stirred until it became turbid to form an emulsion. The prepared emulsion was aged for 24 h, centrifuged at 6000 rad / min and washed 3 times to obtain a white paste. The prepared white paste was dried in a blast dryer at 60°C for 8 hours, and dried in a vacuum oven at 105°C for 6 hours to obtain a ZIF-8 zeolite imidazolate skeleton;

[0038] (2) Grind the dried ZIF-8 material in an agate mortar for 30 min, and keep it in a tube furnace with a nitrogen atmosphere at 800 °C for 5 h ...

Embodiment 3

[0044] A preparation method of a lead-carbon battery negative electrode based on a ZIF-8 zeolite imidazolate framework porous carbon nanomaterial, comprising the following steps:

[0045] (1) Under the condition of magnetic stirring, 7.71g metal nitrate Zn(NO 3 ) 2 ·6H 2 O was dissolved in 750ml of anhydrous methanol to form a colorless and clear solution A; 9.84g of organic ligand 2-methylimidazole was dissolved in the above solution to form a clear solution B, and the clear solution B continued to be magnetically stirred until it became turbid to form an emulsion. The prepared emulsion was aged for 24 h, centrifuged at 7000 rad / min and washed 3 times to obtain a white paste. The prepared white paste was dried in a blast dryer at 60°C for 8 hours, and dried in a vacuum oven at 105°C for 6 hours to obtain a ZIF-8 zeolite imidazolate skeleton;

[0046] (2) Grind the dried ZIF-8 material in an agate mortar for 30 min, and keep it in a tube furnace with a nitrogen atmosphere a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com