Catalyst for preparing sodium gluconate

A technology of sodium gluconate and catalyst, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, carboxylate preparation, etc., can solve the problems such as the introduction of Bi metal and difficulty in catalyst recovery, and achieve good catalytic effect. , the effect of large economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

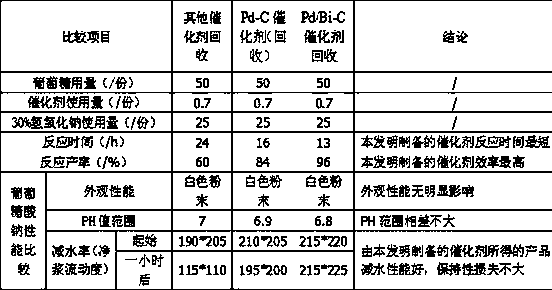

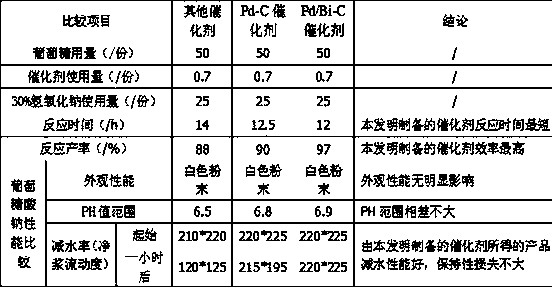

Examples

Embodiment 1

[0036] A catalyst for preparing sodium gluconate, consisting of the following components: Pretreated activated carbon powder: 80 parts, bismuth nitrate: 0.8 parts, palladium chloride: 0.8 parts, hydrochloric acid: 12 parts, distilled water: 220 parts Parts, sodium borohydride: 2 parts.

[0037] The described catalyst that is used to prepare sodium gluconate, gac pretreatment is to wash 300 mesh gac with 5% sodium hydroxide alkali of 4 times of amount, filter dry, wash with water to Ph value neutrality, then use 4 times of amount of Pickle with 5% hydrochloric acid / nitric acid solution, add 0.04 times the amount of salicylic acid to participate in the complexation reaction, wash with 8 times distilled water until the pH value is neutral.

Embodiment 2

[0039] A catalyst for preparing sodium gluconate, consisting of the following components: pretreated activated carbon powder: 60 parts, bismuth nitrate: 0.6 parts, palladium chloride: 0.6 parts, hydrochloric acid: 8 parts, distilled water: 200 parts Parts, sodium borohydride: 1 part.

[0040] The described catalyst that is used to prepare sodium gluconate, gac pretreatment is to wash 300 mesh gac with 5% sodium hydroxide alkali of 4 times of amount, filter dry, wash with water to Ph value neutrality, then use 4 times of amount of Pickle with 5% hydrochloric acid / nitric acid solution, add 0.04 times the amount of salicylic acid to participate in the complexation reaction, wash with 8 times distilled water until the pH value is neutral.

Embodiment 3

[0042] Described catalyst for preparing sodium gluconate, its component parts by weight are: activated carbon powder after pretreatment: 70 parts, bismuth nitrate: 0.7 part, palladium chloride: 0.7 part, hydrochloric acid: 10 parts, distilled water: 210 parts, sodium borohydride: 1.5 parts.

[0043] The present invention relates to a kind of catalyst that is used for preparing sodium gluconate, and its specific mode of operation is as follows:

[0044] 1. Pretreatment of activated carbon:

[0045] (1) Material preparation: design of weight components: 300 mesh activated carbon: 100 parts; 5% sodium hydroxide: 400 parts; 5% hydrochloric acid / nitric acid solution: 400 parts; salicylic acid: 4 parts; distilled water: 800 parts ;

[0046] (2) Preparation specific operation steps:

[0047] 1. Take 100 parts of 300-mesh activated carbon powder and add 400 parts of 5% sodium hydroxide solution, boil for 30 minutes;

[0048] 2. After reacting for 30 minutes, suction filter the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com