Synthetic method for organically compounding intermediate cyanogen

A technology for the synthesis of ethanedinitrile and a synthetic method, which is applied in the field of synthesis of the organic synthesis intermediate ethanedinitrile, can solve the problems of low final yield and complicated process, shorten the reaction time, reduce intermediate links, and improve the reaction rate. Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

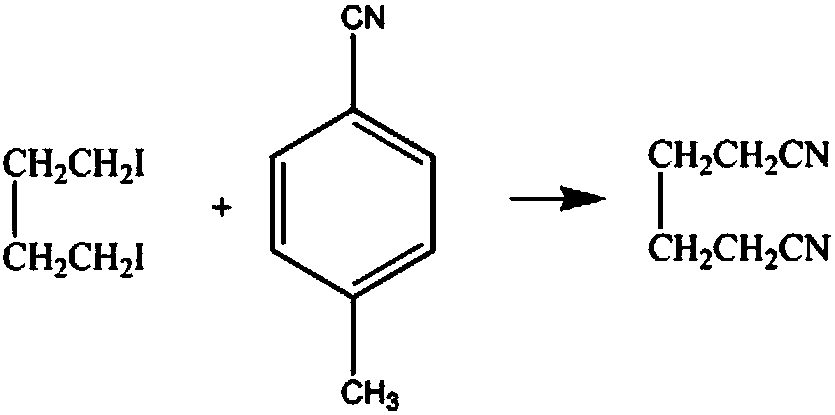

Method used

Image

Examples

example 1

[0011] Dissolve 5mol of 1,4-diiodobutane in 5L of 30% acetone solution, control the stirring speed at 110rpm, add 6mol of 4-methyl-benzonitrile, raise the temperature of the solution to 60℃, and reflux for 90min , Reduce the temperature of the solution to 10℃, filter, wash the filter cake with 50% methylamine solution with mass fraction, pour into 20% potassium iodide solution with mass fraction, and the oil layer should be washed with sodium chloride solution, mass fraction is 70% Washing with pentane solution, washing with 80% ethyl acetate solution with mass fraction, 30kPa vacuum distillation, collecting 50°C fractions, dehydrating with anhydrous sodium sulfate dehydrating agent, to obtain 480.6g of finished oxonitrile with a yield of 89%.

example 2

[0013] Dissolve 5mol of 1,4-diiodobutane in 5L of 32% acetone solution, control the stirring speed to 130rpm, add 6.5mol of 4-methyl-benzonitrile, raise the temperature of the solution to 65℃, and reflux 100min, reduce the temperature of the solution to 12℃, filter, wash the filter cake with a mass fraction of 52% methylamine solution, pour into a 23% potassium iodide solution, and then layer the oil layer with sodium chloride solution, the mass fraction is 72 Wash with %pentane solution, wash with 82% ethyl acetate solution, 35kPa vacuum distillation, collect the 52°C distillate, and dehydrate with anhydrous potassium carbonate dehydrating agent to obtain 491.4g of finished oxonitrile with a yield of 91%.

example 3

[0015] Dissolve 5mol of 1,4-diiodobutane in 5L of 35% acetone solution, control the stirring speed at 150rpm, add 7mol of 4-methyl-benzonitrile, raise the temperature of the solution to 70℃, and reflux for 110min , Reduce the temperature of the solution to 15℃, filter, wash the filter cake with a 55% mass fraction of methylamine solution, pour into a 27% mass fraction of potassium iodide solution, layering occurs, and wash the oil layer with sodium chloride solution, with a mass fraction of 75% Washing with pentane solution, washing with 85% ethyl acetate solution with mass fraction, 40kPa vacuum distillation, collecting 55°C distillate, dehydrating with anhydrous sodium sulfate dehydrating agent, to obtain 507.6g of finished oxonitrile with a yield of 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com