Precise temperature-controlled liquid reservoir for mechanical pump driving two-phase fluid circuit and assembly method

A fluid circuit and liquid storage technology, which is applied in the field of precision temperature-controlled liquid storage and assembly of two-phase fluid circuits driven by mechanical pumps. problems, to achieve the effects of improved structural mechanical properties, high cooling capacity utilization, and direct heat transfer methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

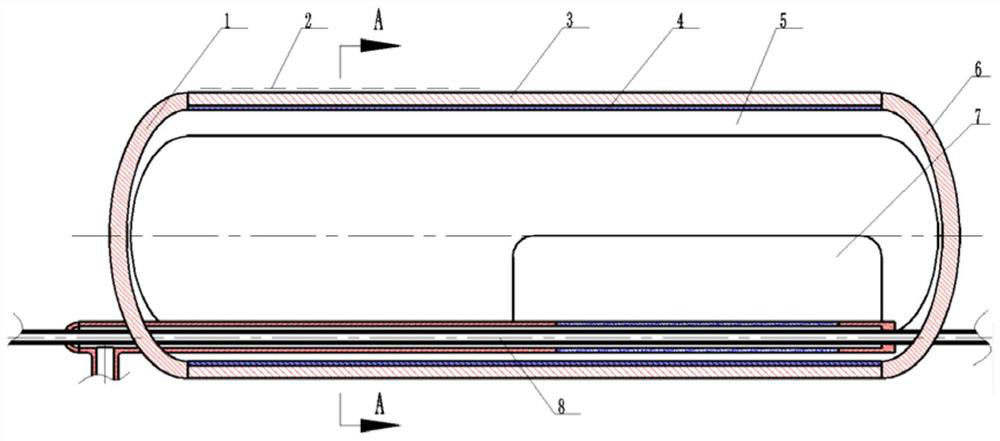

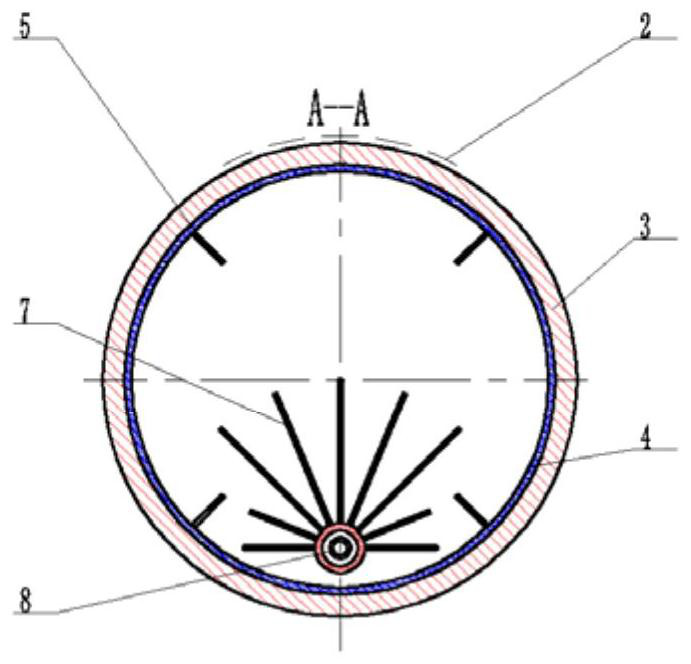

[0033] Aiming at the deficiencies of the prior art, the present invention proposes a precision temperature-controlled liquid storage device for a two-phase fluid circuit driven by a mechanical pump, including a left end head 1, a heating device 2, a cylinder body 3, and a capillary structure lining the cylinder body 4. Flow guiding device 5, right end head 6, liquid collector 7 and passive cooling capillary drain 8.

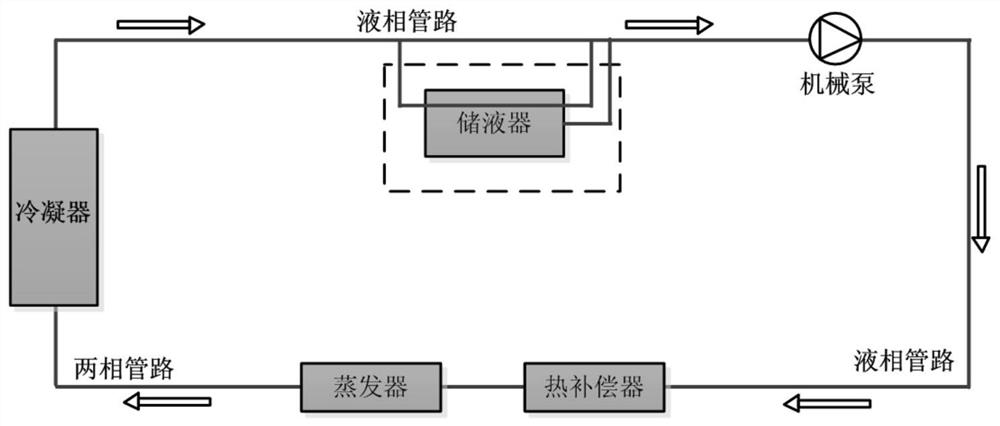

[0034] Such as figure 1 The schematic diagram of the two-phase temperature-controlled fluid circuit driven by a mechanical pump is shown. The left end head 1, the cylinder body 3, and the right end head 6 are connected by welding to form the liquid storage shell. The surface is bonded by welding, the heating device 2 is pasted on the outer wall of the cylinder, the flow guide device 5 is a perforated metal plate, fixed on the inner surface of the shell and distributed radially, and the passive cooling capillary drain structure 8 includes an outer sleeve Drain en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com