Patterned sapphire substrate combining laser etching misplaced hemisphere and ODRs (Omni-directional Reflectors) and preparation method

A sapphire substrate, laser etching technology, applied in the field of optoelectronics, can solve problems such as unfavorable light extraction, and achieve the effects of improving light extraction efficiency, easy control of patterns, and increased light extraction opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

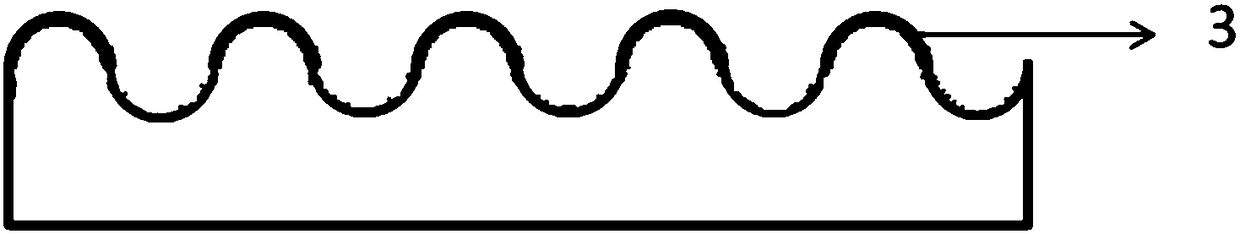

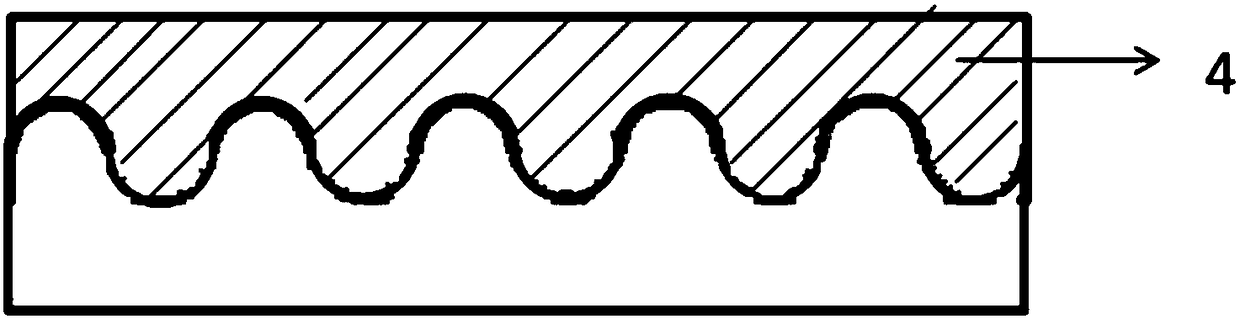

[0042] A sapphire pattern substrate combined with laser etching dislocation hemispheres and ODR, the substrate surface is provided with hemispherical protrusions, the substrate between two adjacent hemispherical protrusions is provided with hemispherical grooves, and the diameter of the hemispherical protrusions is 5 μm, the distance between two adjacent hemispherical protrusions is 5 μm; the surface of the hemispherical protrusions is provided with a mirror layer, and the mirror layer is TiO 2 / SiO 2 layer, the thickness of the mirror layer is 200nm.

[0043] Among them, TiO 2 / SiO 2 The layers are alternately grown SiO 2 layer and TiO 2 layer, the alternating repetition period is 1, that is, a SiO2 layer+TiO2 layer is alternately grown. Alternately grown SiO in 1 alternate repeating cycle 2 layer thickness of 100 nm, alternately grown TiO 2 The layer thickness was 100 nm.

Embodiment 2

[0045] A sapphire pattern substrate combined with laser etching dislocation hemispheres and ODR, its structure is as described in Example 1, the difference is that the diameter of the hemispherical protrusions is 1 μm, and the distance between two adjacent hemispherical protrusions is 1 μm.

Embodiment 3

[0047] A sapphire pattern substrate combined with laser etching dislocation hemisphere and ODR, its structure is as described in embodiment 1, the difference is that the mirror layer is Au 2 O / SiO 2 layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com