Alkali halide-doped perovskite light-emitting diode and fabrication method thereof

A technology of alkali metal halides and light-emitting diodes, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as slow charge transfer efficiency, improve film morphology, improve device efficiency, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

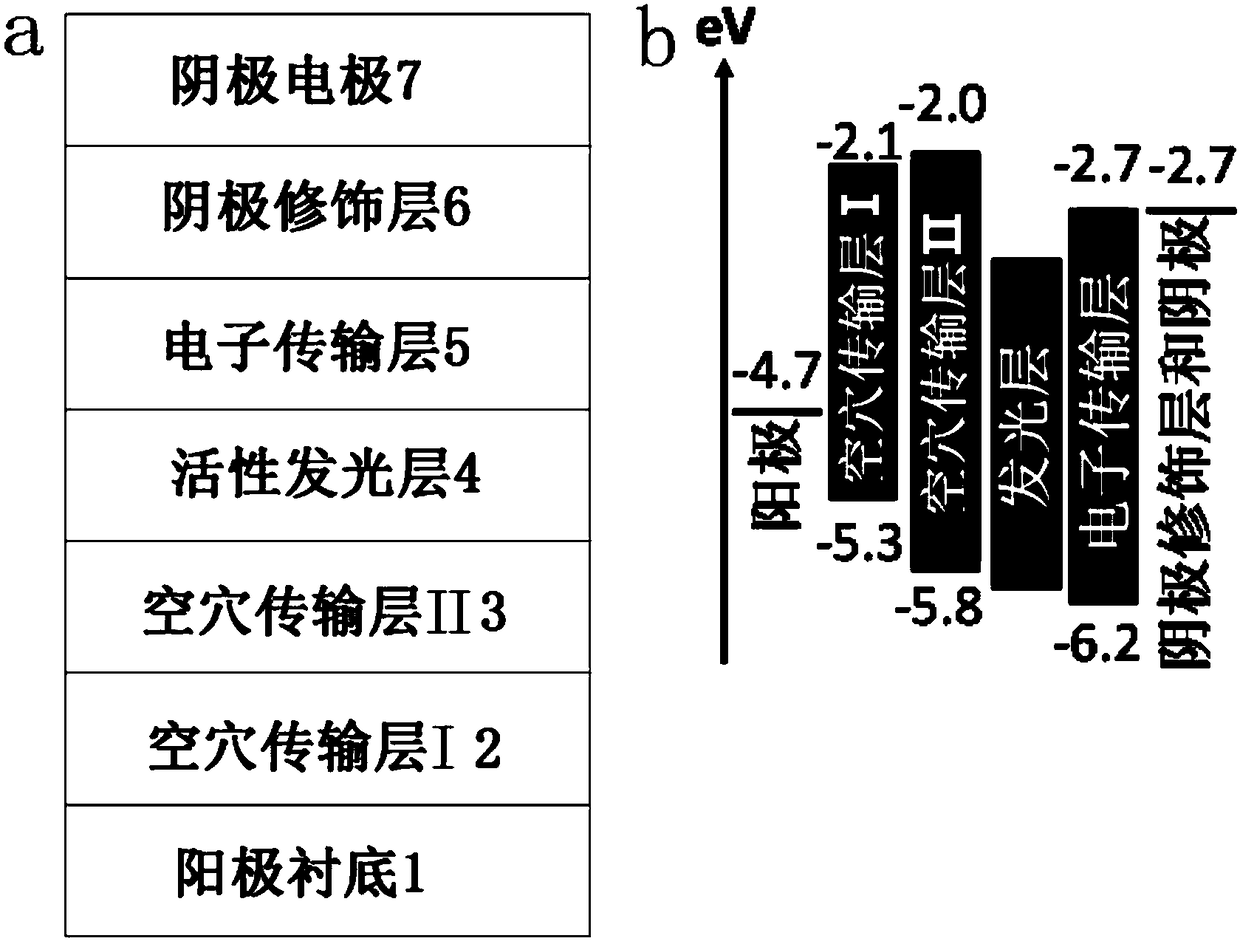

[0069] This embodiment provides an alkali metal halide-doped perovskite light-emitting diode, including an anode substrate 1 (thickness is 150nm), a hole transport layer (thickness is 40nm), an active light emitting diode arranged in sequence from bottom to top. Layer 4 (thickness is 40nm), electron transport layer 5 (thickness is 40nm), cathode modification layer 6 (thickness is 1nm) and cathode 7 (thickness is 100nm), wherein the hole transport layer comprises hole transport layer I 2 and hole Hole transport layer II 3. Its preparation method is as follows:

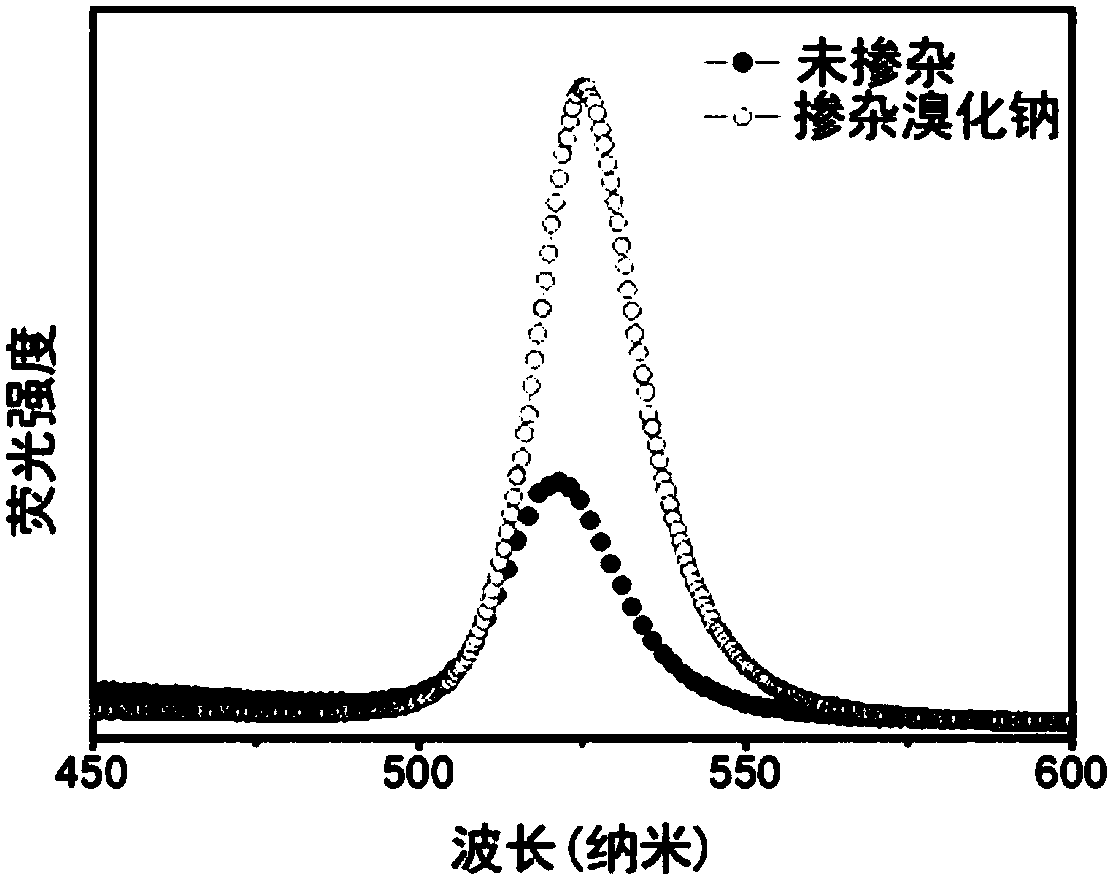

[0070] Using dimethyl sulfoxide (DMSO) as solvent to prepare perovskite precursor solution doped with alkali metal bromide, including perovskite precursors CsBr and PbBr 2 And the alkali metal bromide NaBr, the molar ratio of the three is CsBr:NaBr:PbBr 2 =1:0.1:1, CsBr and PbBr in the precursor solution 2 The optimal concentration is 0.2M, and the concentration of NaBr is 0.1M.

[0071] Dissolve TFB in chlorobenzen...

Embodiment 2

[0080] This embodiment provides an alkali metal halide-doped perovskite light-emitting diode, including an anode substrate 1 (thickness is 150nm), a hole transport layer (thickness is 40nm), an active light emitting diode arranged in sequence from bottom to top. Layer 4 (thickness is 40nm), electron transport layer 5 (thickness is 40nm), cathode modification layer 6 (thickness is 1nm) and cathode 7 (thickness is 100nm), wherein the hole transport layer comprises hole transport layer I 2 and hole Hole transport layer II 3. Its preparation method is as follows:

[0081] Using dimethyl sulfoxide (DMSO) as solvent to prepare perovskite precursor solution doped with alkali metal bromide, including perovskite precursors CsBr and PbBr 2 And the alkali metal bromide KBr, the molar ratio of the three is CsBr:KBr:PbBr 2 =1:0.1:1, precursor solution CsBr and PbBr 2 The optimal concentration is 0.2M, and the concentration of KBr is 0.1M.

[0082] Dissolve TFB in chlorobenzene to confi...

Embodiment 3

[0090] This embodiment provides an alkali metal halide-doped perovskite light-emitting diode, including an anode substrate 1 (thickness is 150nm), a hole transport layer (thickness is 40nm), an active light emitting diode arranged in sequence from bottom to top. Layer 4 (thickness is 40nm), electron transport layer 5 (thickness is 40nm), cathode modification layer 6 (thickness is 1nm) and cathode 7 (thickness is 100nm), wherein the hole transport layer comprises hole transport layer I 2 and hole Hole transport layer II 3. Its preparation method is as follows:

[0091] Using dimethyl sulfoxide (DMSO) as solvent to prepare perovskite precursor solution doped with alkali metal bromide, including perovskite precursors CsBr and PbBr 2 And the alkali metal bromide RbBr, the molar ratio of the three is CsBr:RbBr:PbBr 2 = 1:0.1:1, CsBr and PbBr 2 The optimal concentration is 0.2M, and the concentration of RbBr is 0.1M.

[0092] Dissolve TFB in chlorobenzene to configure a precurso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com