Liquid material heat-preservation device and application thereof

A technology of heat preservation device and material, applied in the field of material heat preservation, can solve the problems of high cost of automatic control system, unclean cleaning, insufficient speed, etc., and achieve simple control instrument and automatic control system, continuously adjustable heat preservation time, and high energy recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

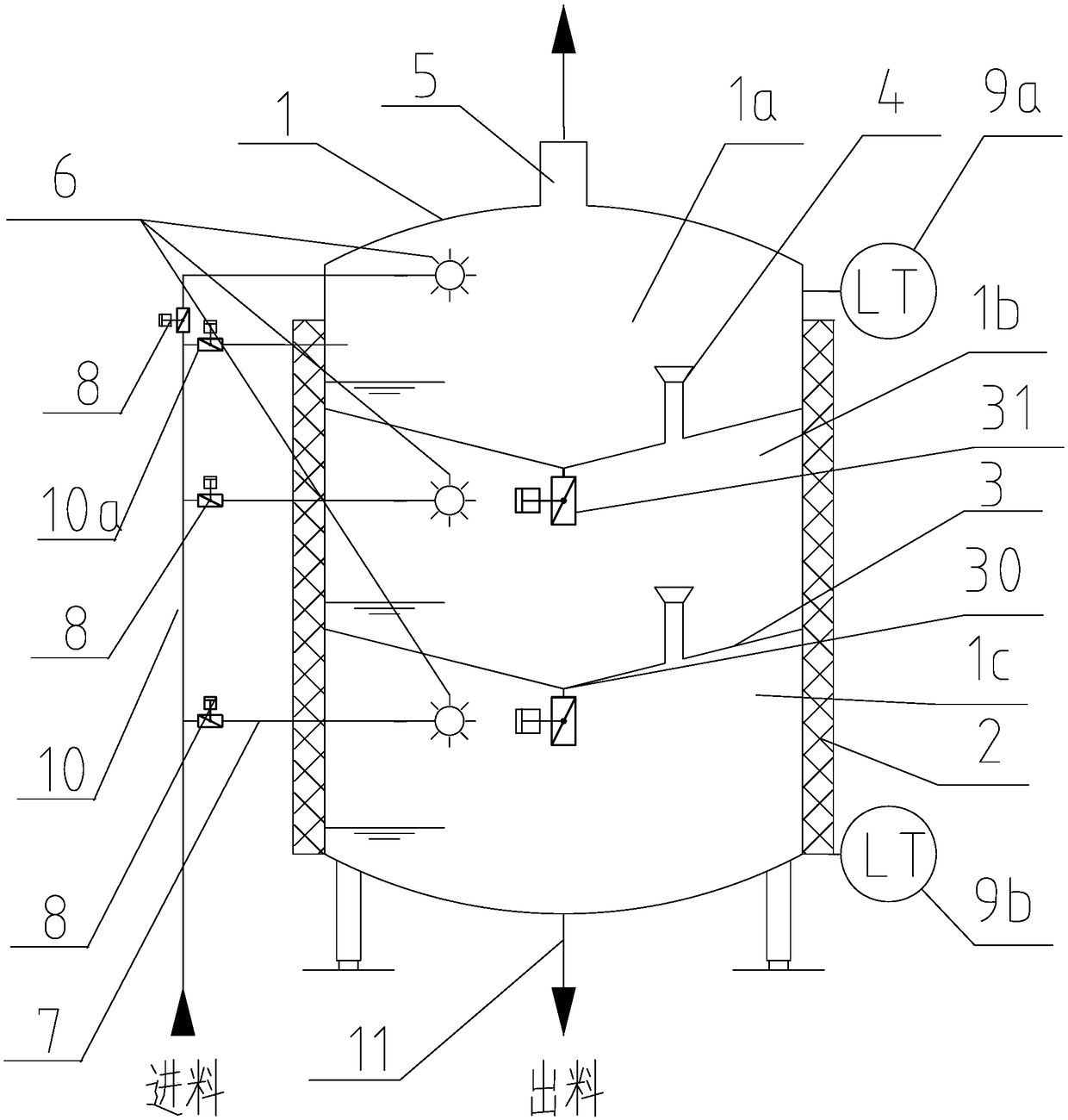

[0076] Such as figure 1Shown, a kind of liquid material insulation device, this insulation device includes insulation tower, control system (not shown in the figure), instruments such as flow meter etc. (not shown in the figure, can be set according to the conventional means of this field). The heat preservation tower includes a tower body 1 arranged upright, an insulation layer 2 arranged on the outer periphery of the tower body 1, and two partitions 3 horizontally arranged in the tower body 1. The two partitions 3 separate the tower body 1 into upper, middle and The lower three interlayers (hereinafter respectively referred to as feed layer 1a, insulation layer 1b and discharge layer 1c), feed layer 1a and discharge layer 1c are respectively provided with liquid level sensors 9a, 9b, feed layer 1a and feed layer The pipe 10 is connected, and the discharge layer 1c is connected with the discharge pipe 11. The feed pipe 10 and the discharge pipe 11 are respectively provided wi...

Embodiment 2

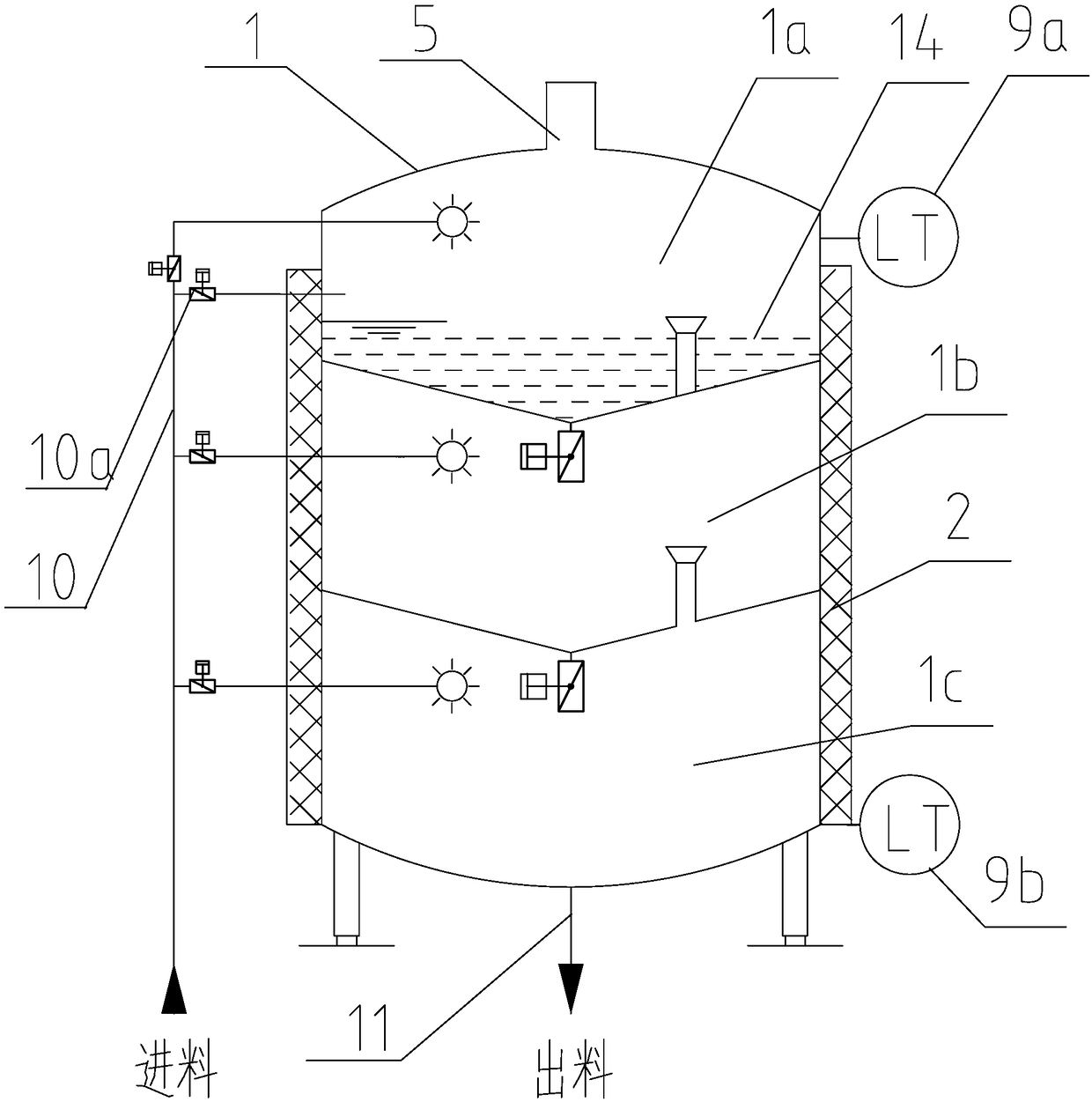

[0088] Such as Figure 6 As shown, this embodiment provides a liquid material heat preservation device, which is basically the same as Embodiment 1, the difference is that there are 4 partitions in this example, so that the inner space of the tower body 1 is divided into 5 partitions.

[0089] The method of adopting this embodiment to carry out material insulation is the same as that of Embodiment 1, except that the setting value and residence time of the control materials in each compartment are different. Specifically, the flow rate of the liquid material to be insulated is 30m 3 / h, the holding time is 30 minutes as an example, the material setting value of the control switch valve is 30m 3 / h* 0.5h / 3=5m 3 . The material residence time in each insulation layer is 10min. From the beginning of feeding to the subsequent stable cycle, the total time required is 50 minutes. During the entire continuous heat preservation process, there is a total of 80 minutes of heat energy ...

Embodiment 3

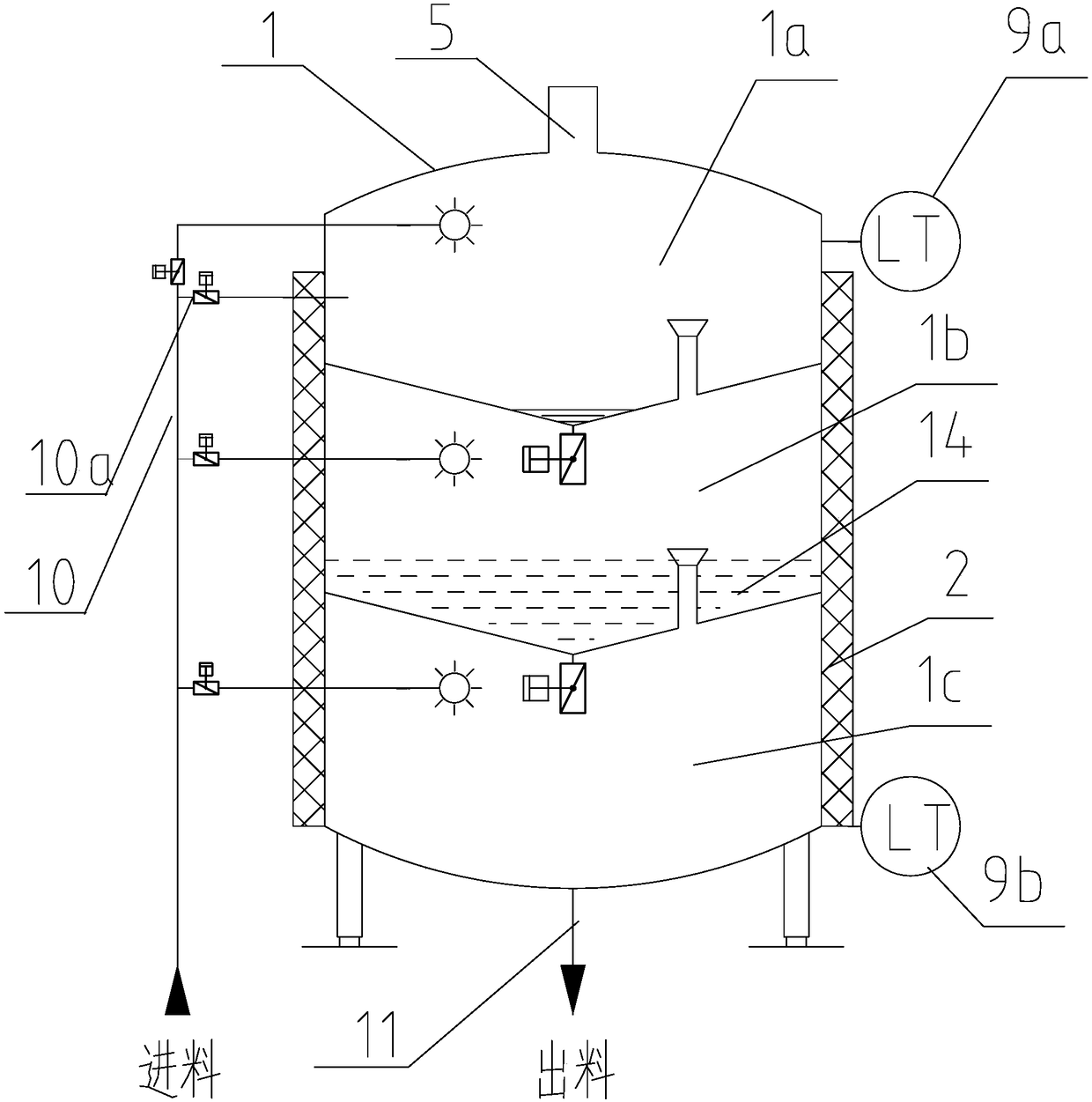

[0091] This embodiment provides a liquid material heat preservation device, which is basically the same as Embodiment 2, except that there are 5 partitions in this example, so that the inner space of the tower body is divided into 6 partitions.

[0092] The flow rate of the liquid material to be insulated is 30m 3 / h, the holding time is 30 minutes as an example, the material setting value of the control switch valve is 30m 3 / h*0.5h / 4=3.75m 3 . The residence time of materials in each insulation layer is 7.5 minutes. From the beginning of feeding to the subsequent stable cycle, the total time required is 45 minutes. During the entire continuous heat preservation process, there is a total of 75 minutes of heat energy that has not been recovered. Correspondingly, the volume of each compartment can be set to 3.75m 3 Or slightly more than 3.75m 3 , the total volume of the tower can be about 22m 3 . Compared with Example 1, the volume of the tower body can be reduced by 50% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com