Reaction device of composite material

A composite material and reaction equipment technology, applied in the field of new materials, can solve the problems of difficult recycling and reuse of hot materials, poor thermal insulation performance of the kettle body, and short stirring time, and achieve the effects of simple structure, improved friction efficiency and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

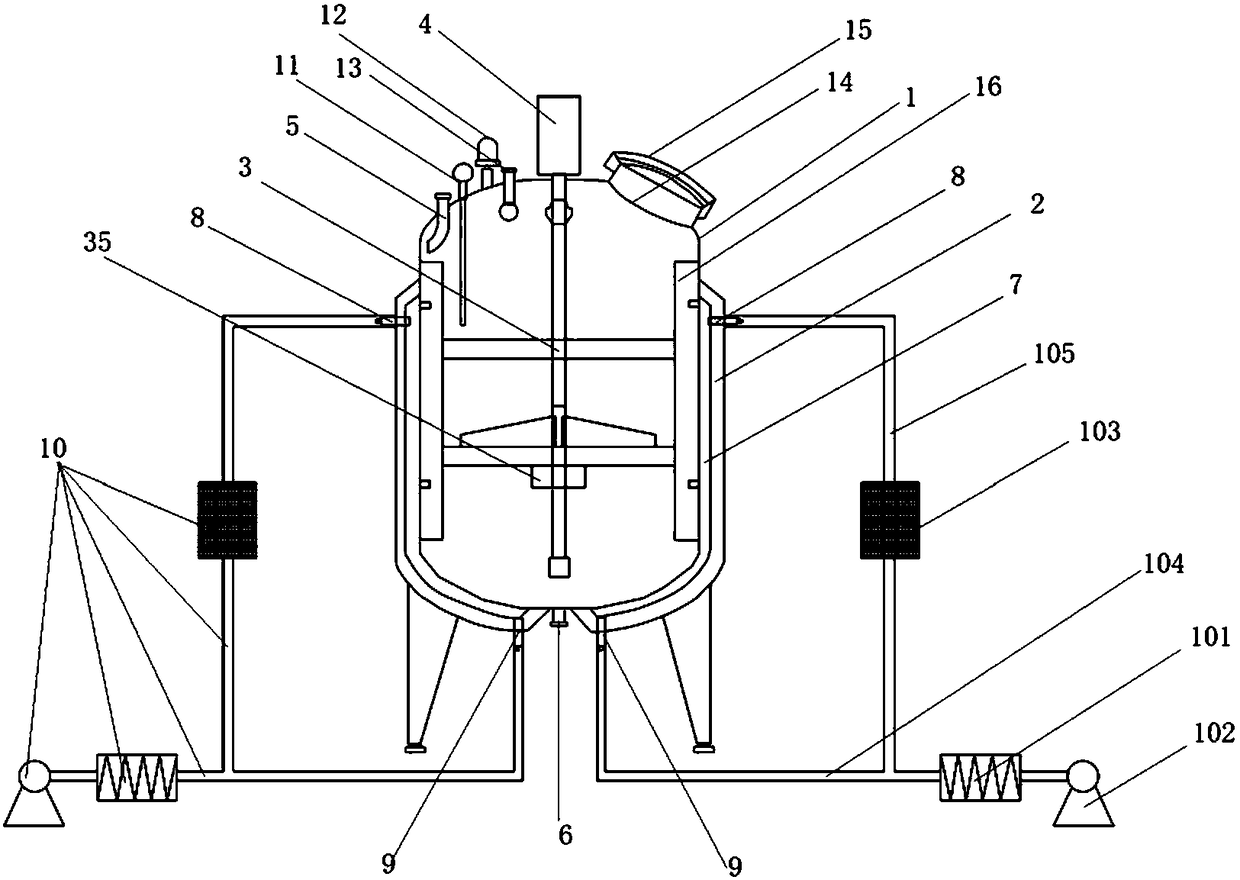

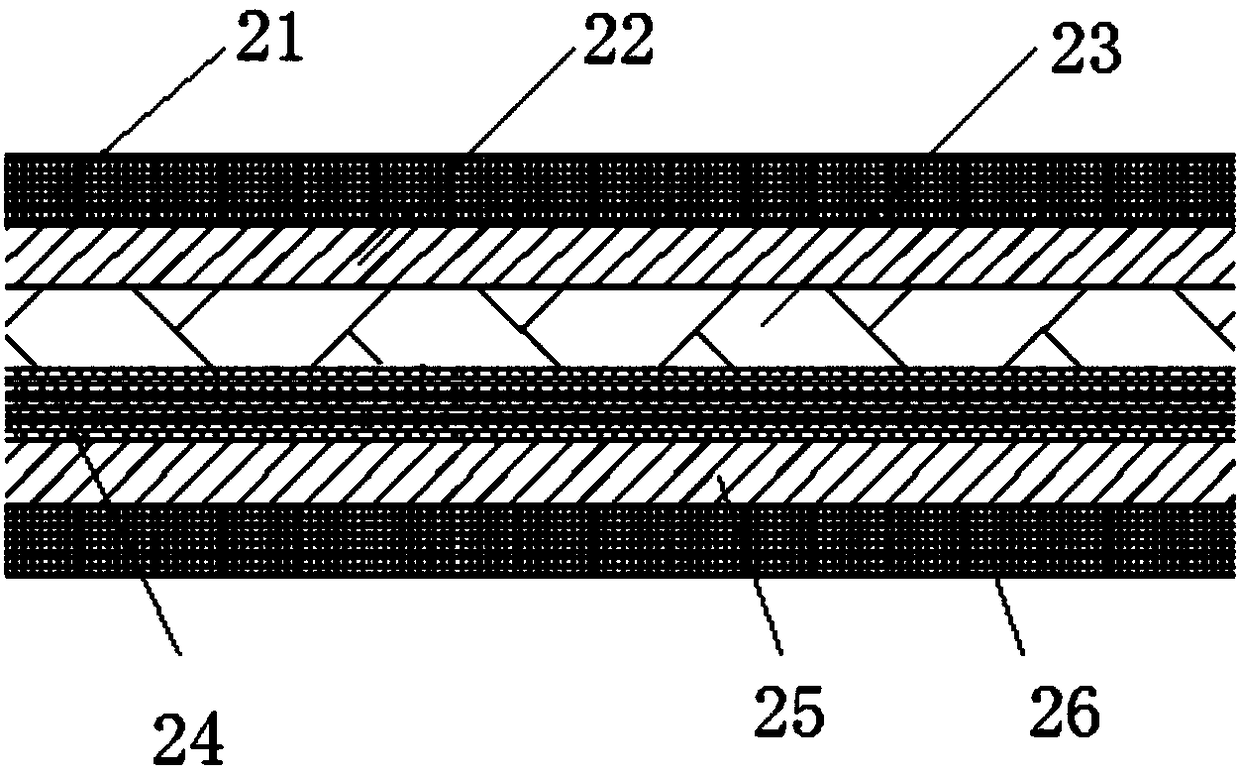

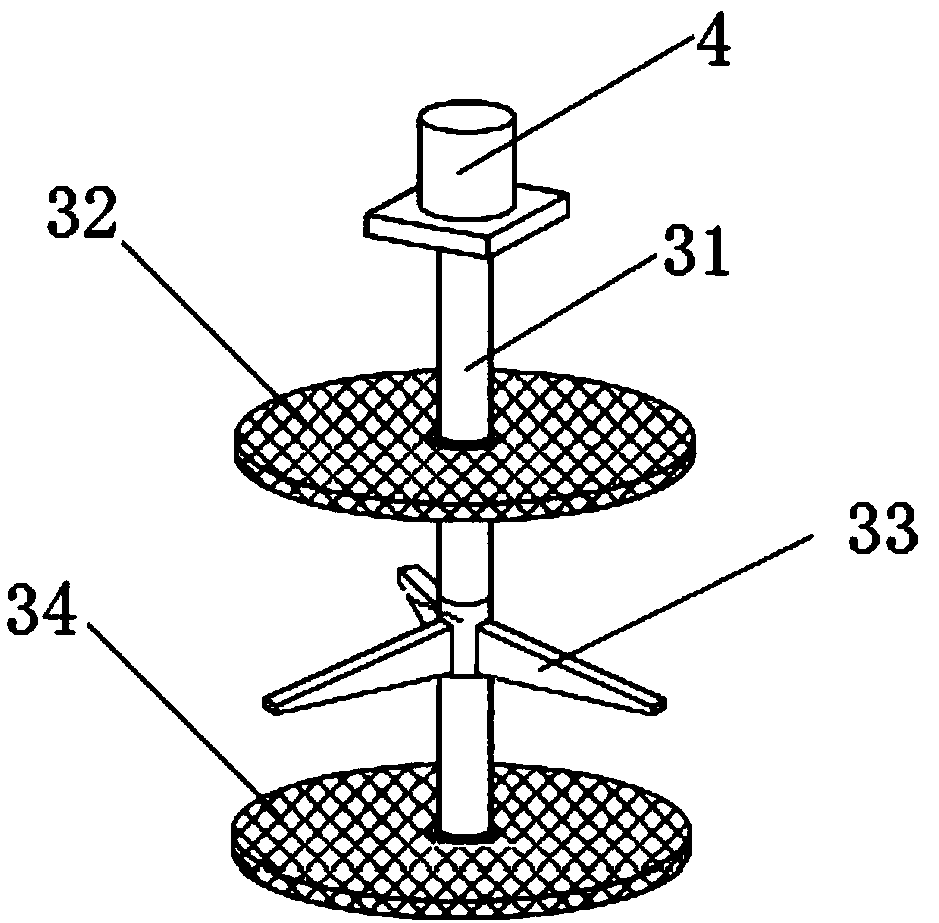

[0019] Such as Figure 1~3 As shown, a reaction device for composite materials includes a device housing 1, a thermal insulation cover 2, a stirring mechanism 3, and a stirring motor 4. The upper part of the device housing 1 is provided with a material inlet 5, and the lower part is provided with a material outlet. 6. The thermal insulation cover 2 is arranged on the outside of the equipment housing 1, and a heating chamber 7 is arranged between the outer wall of the equipment housing 1; the upper part of the heating chamber 7 is provided with an air outlet 8 and the lower part of the heating chamber 7 An air inlet 9 is provided, and a heating mechanism 10 is arranged between the air outlet 8 and the air inlet 9; the stirring mechanism 3 is arranged in the equipment housing 1, and the stirring motor 4 drives the stirring mechanism 3 to mix composite materials ; Wherein, the heat preservation outer cover 2 includes an upper polymer waterproof mortar layer 21, an upper steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com