Supported type Fe2O3 composite photocatalyst

A technology of composite light and catalyst, applied in the field of photocatalysis, to achieve the effect of improving lipophilicity, easy dispersion and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

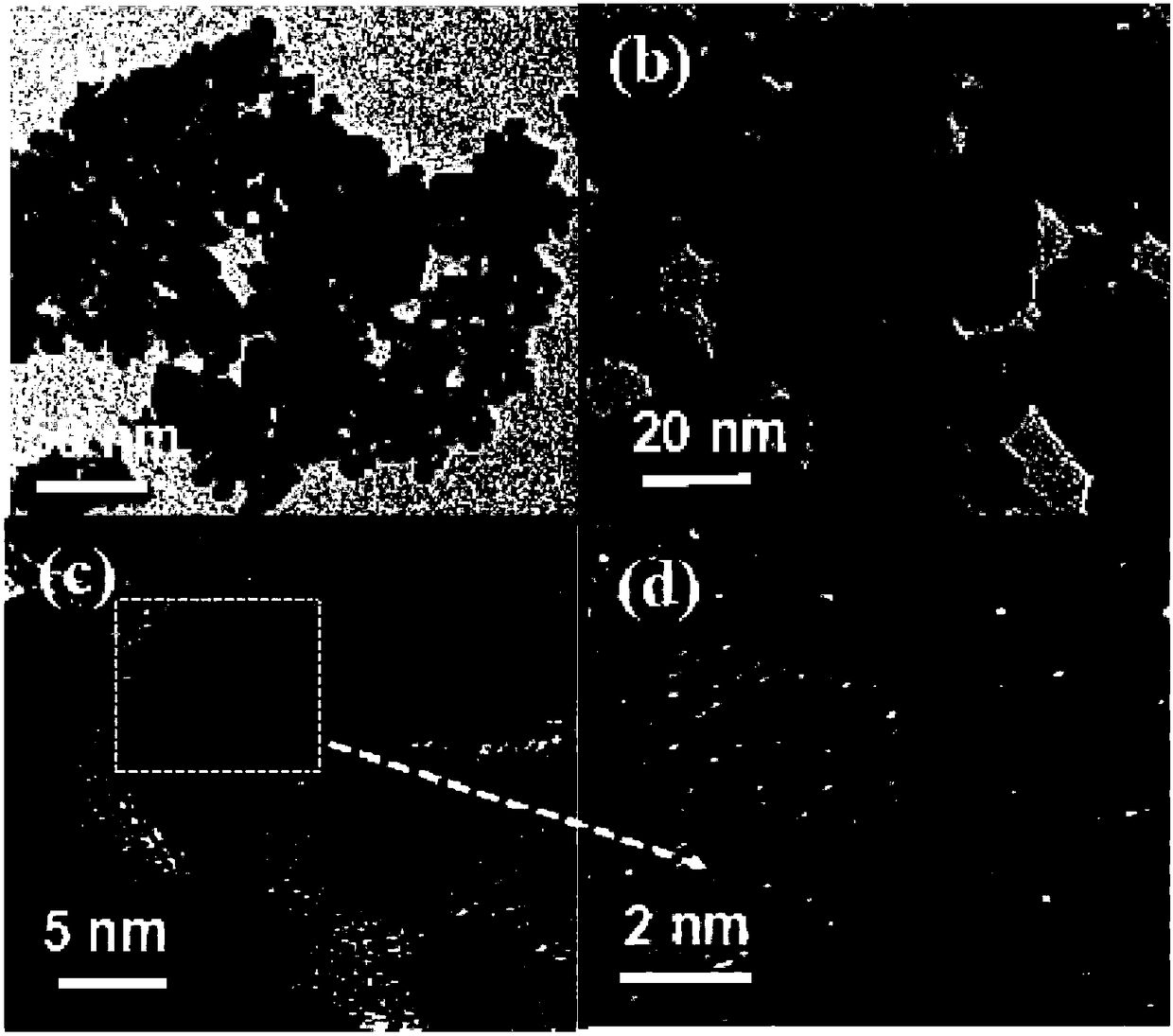

Image

Examples

preparation example Construction

[0027] Embodiments of the present invention also provide a loaded Fe 2 o 3 The preparation method of composite photocatalyst, it comprises the following steps:

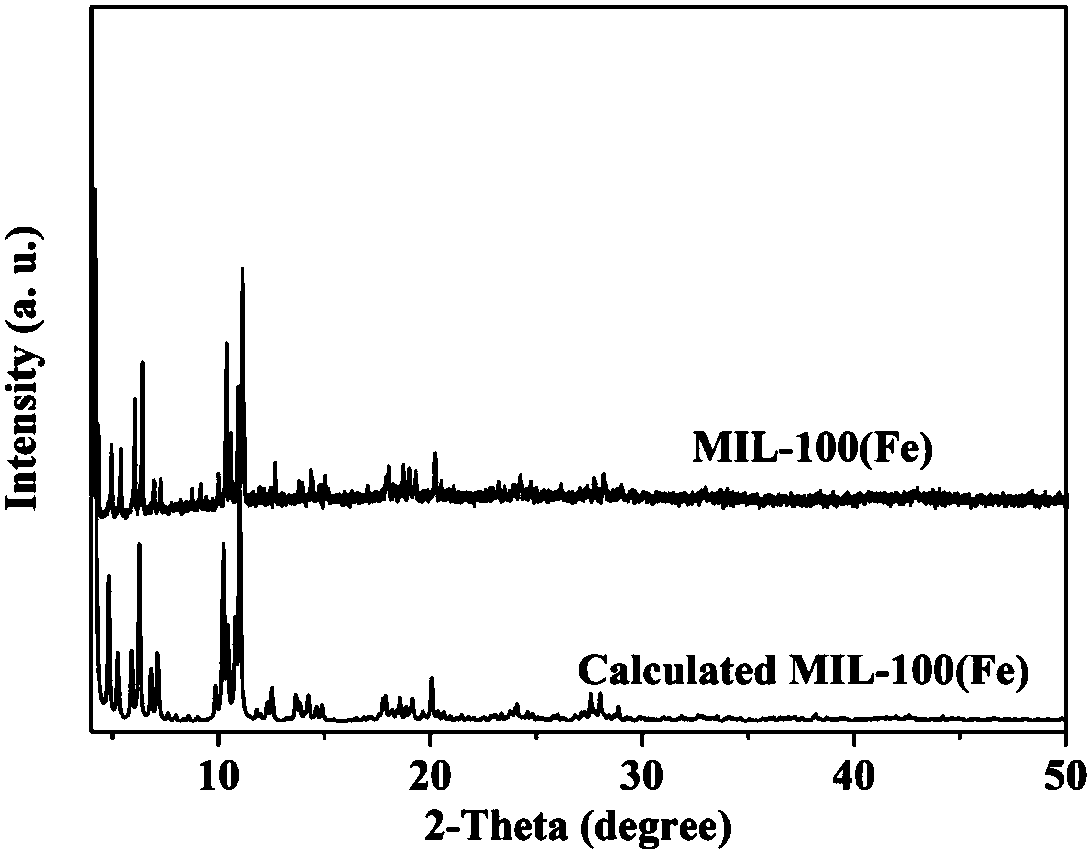

[0028] S1, synthesis of metal-organic framework MIL-100(Fe): dissolve iron salt in water, add 1,3,5-trimethyl benzenetricarboxylate, react in a closed state at 120-150°C for 2-5 days, separate , washing and drying to obtain MIL-100(Fe);

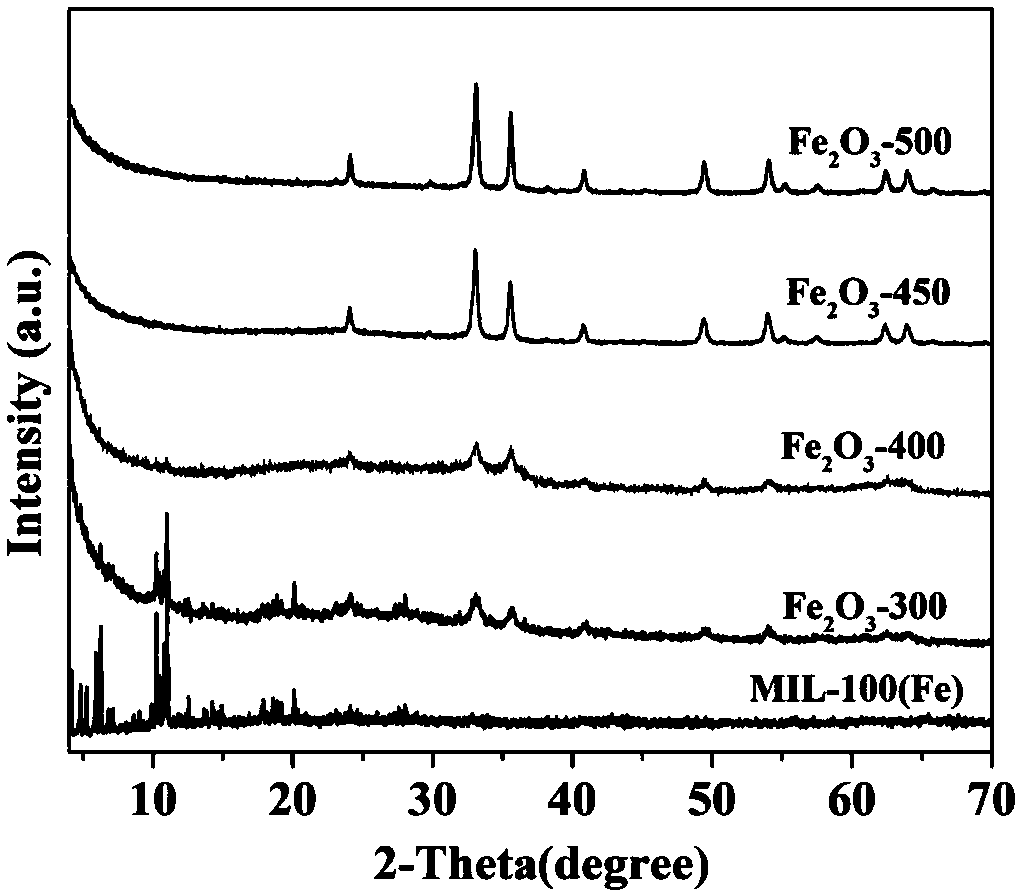

[0029] S2, porous Fe 2 o 3 Synthesis: heating the MIL-100(Fe) at the first heating rate to the first temperature for 1.5 to 3 hours, then heating at the second heating rate to the second temperature, and cooling down immediately to obtain the porous Fe 2 o 3 , wherein, the first temperature is 280-300°C, and the second temperature is 400-500°C;

[0030] S3, SDS / Fe 2 o 3 Synthesis: the porous Fe 2 o 3 Dispersed in SDS solution, separated, washed and dried after adsorption reaction for 1-3 hours, wherein the concentration of the SDS solution is 0.125-0.5g / L.

[0031] Further...

Embodiment 1

[0045] This embodiment provides a porous Fe 2 o 3 Photocatalyst, it is prepared according to the following steps:

[0046] (1) 0.378g of FeCl 3 ·6H 2 O is added to the lining of polytetrafluoroethylene, and then 10ml of deionized water is added. After completely dissolving, add 0.272g of 1,3,5-trimethyl benzenetricarboxylate and magnetically stir for about 5min, then put the lining into the reaction kettle. After the stainless steel outer lining is tightened, put it into an oven to keep warm at 130°C for 3 days, and then cool down to room temperature naturally. After the reaction, use a high-speed centrifuge at a speed of 8000r / min to centrifuge for 10 minutes, then ultrasonically wash 6 times with methanol, and place it in an oven (80°C) to insulate and dry. The prepared sample is the MIL-100(Fe) sample .

[0047] (2) Take the above MIL-100(Fe) material, grind the solid product with an agate mortar, put it in a ceramic crucible, place it in a muffle furnace at a heating ...

Embodiment 2

[0049] This embodiment provides a porous Fe 2 o 3 Photocatalyst, its difference with embodiment 1 is:

[0050] In step (2), continue to raise the temperature to 400° C. at a rate of 1° C. / min and then drop the temperature immediately. labeled as Fe 2 o 3 -400.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com