Inorganic metal oxide ion storage layer, processing method and application of low-temperature solution of inorganic metal oxide ion storage layer

A technology of inorganic metals and oxide layers, applied in the fields of instruments, nonlinear optics, optics, etc., can solve problems such as complex processing procedures, affecting adhesion ability, and limiting use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] TiO 2 Preparation of the ion storage layer

[0057] Add 2 ml of isopropanol solution in the vial, then add 0.66 ml of Ti(OCH(CH 3 ) 2 ) 4 . Sonicate for 10 minutes in an ultrasonic sample disruptor and add 100 microliters of acetic acid as a ligand. The prepared solution can be directly processed into TiO on the surface of indium tin oxide by solution spin coating at a speed of 1000rpm. 2 film. The film was heat-treated in an oven at 100°C for ten minutes to remove the isopropanol solvent.

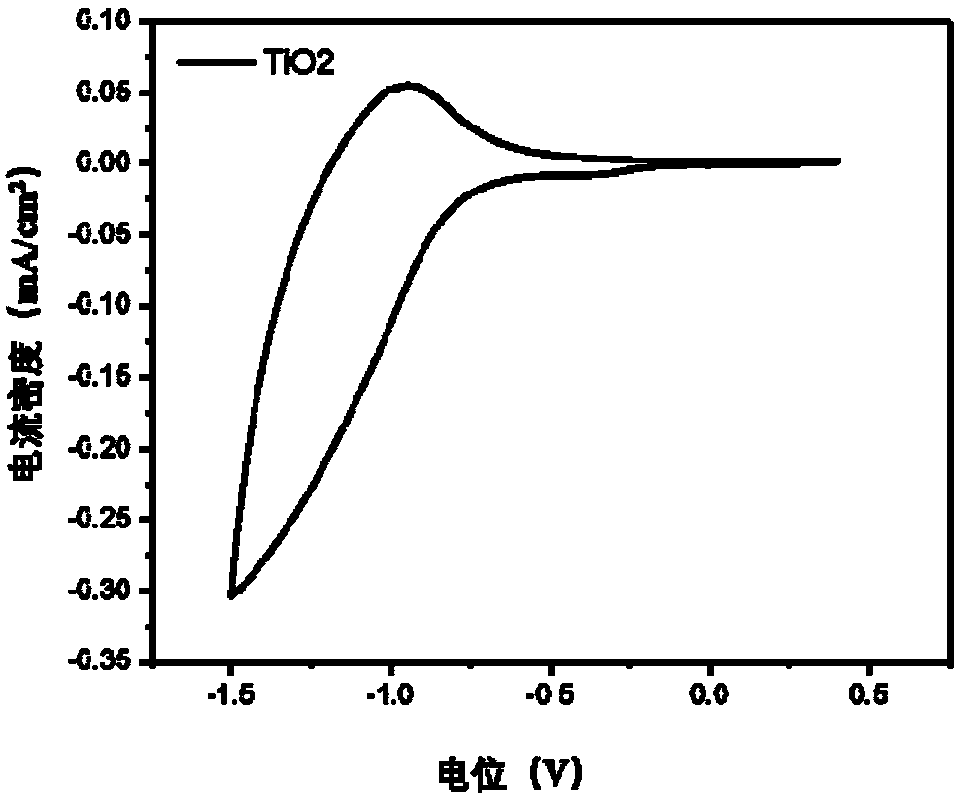

[0058] figure 1 It is the cyclic voltammogram of the titanium oxide ion storage layer in Example 1. It can be seen from the figure that the prepared titanium oxide film has high ion storage capacity and good electrochemical reversibility.

Embodiment 2

[0060] MoO 3 Preparation of the ion storage layer

[0061] Add 2 mL of isopropanol solution to the vial, followed by 100 µL of acetic acid and 0.66 mL of MoCl 3 . Sonicate for 10 minutes in an ultrasonic sample disruptor. The prepared solution can be directly processed into MoO on the surface of indium tin oxide by solution spin coating method at a speed of 1000rpm 3 film. The film was heat-treated in an oven at 120°C for ten minutes to remove the isopropanol solvent.

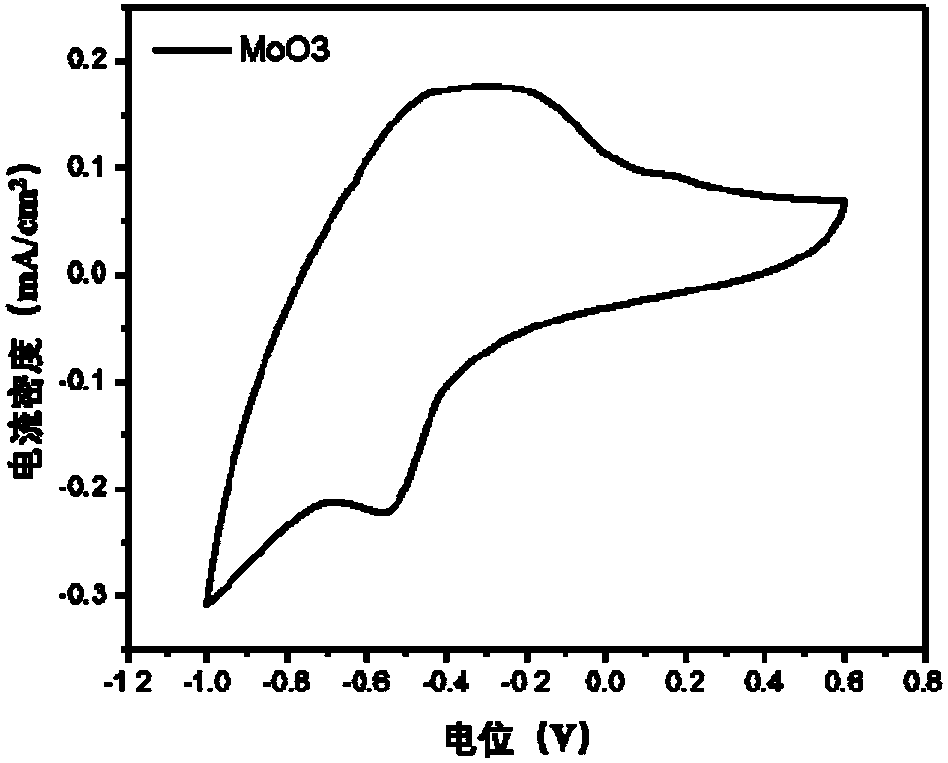

[0062] figure 2 It is the cyclic voltammogram of the molybdenum oxide ion storage layer in Example 2. It can be seen from the figure that the prepared molybdenum oxide thin film has high ion storage capacity and good electrochemical reversibility.

Embodiment 3

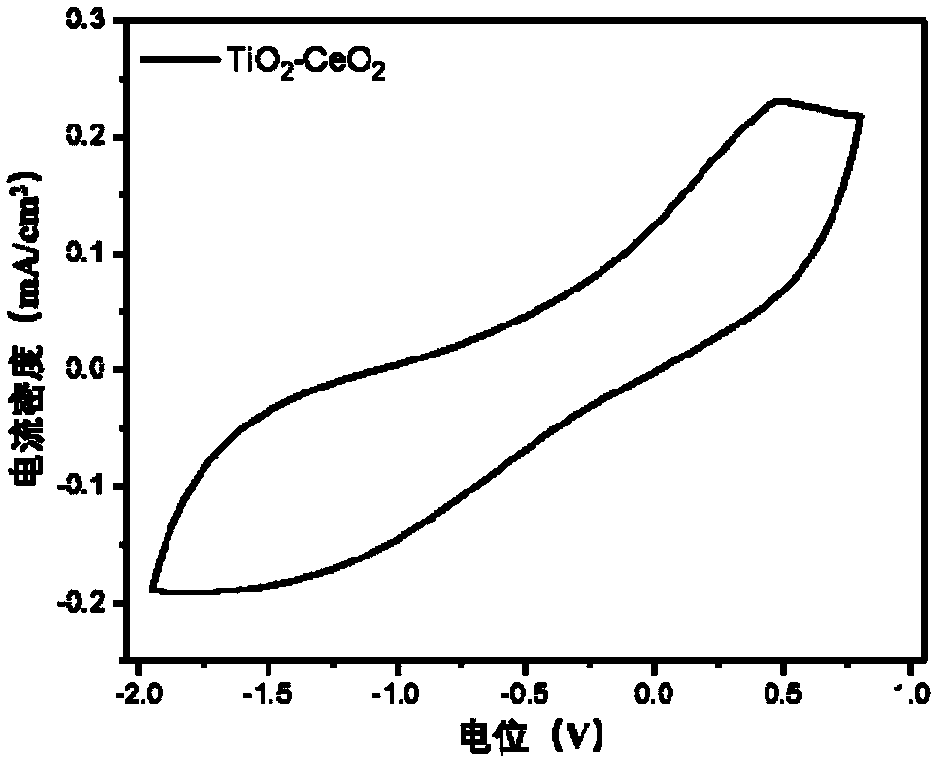

[0064] TiO 2 Doped MoO 3 Preparation of the ion storage layer

[0065] Add 2 mL of isopropanol solution and 10 μL of acetic acid to the vial, followed by 0.66 mL of MoCl 3 . Ti(OCH(CH 3 ) 2 ) 4 Adding it to the MoCl3 solution in a certain proportion can prepare TiO 2 Doped MoO 3 solution. For example, the molar ratio Mo:Ti=2:1, the molar ratio Mo:Ti=3:1, and the molar ratio Mo:Ti=10:1. The prepared solution can be directly processed into TiO on the surface of indium tin oxide by using the solution spin coating method at a speed of 1000rpm. 2 Doped MoO 3 film. The film was heat-treated in an oven at 120°C for ten minutes to remove the isopropanol solvent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com