Tungsten oxide electrochromic thin film with high spectral adjustment range and preparation method thereof

An electrochromic and adjustable range technology, applied in coating and other directions, can solve problems such as increased production cost, waste of raw materials, precipitation, etc., and achieves the effects of low cost, large spectral adjustment range and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation W 18 o 49 method, the steps are as follows:

[0037] (1) Clean the FTO glass sheet with acetone, isopropanol, ethanol;

[0038](2) Dissolve 0.5g oxalic acid in 30ml ethanol, stir for 10min to obtain a clear solution;

[0039] (3) Add 0.1g WCl 6 Dissolve in the clear solution and stir for 20 minutes to obtain a transparent yellow precursor solution;

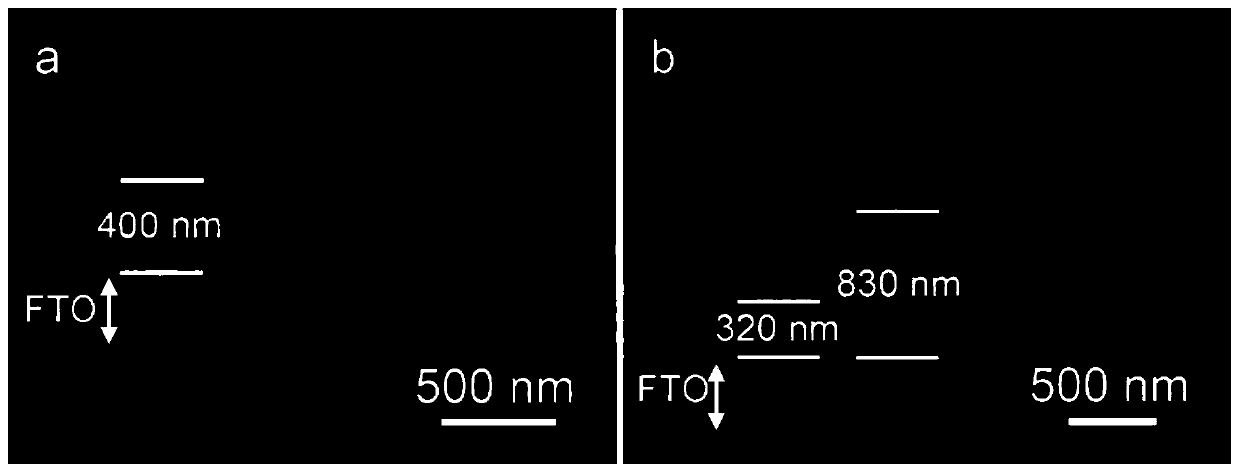

[0040] (4) Put the cleaned FTO glass sheet vertically into the reaction kettle, add the precursor solution filtered through a 0.22 μm organic membrane and cover the glass sheet, and obtain W after solvothermal reaction at 180°C for 10 hours. 18 o 49 - FTO glass samples;

[0041] (5) will W 18 o 49 -FTO glass samples were washed with ethanol and water successively, dried at 60°C, and heat-treated at 200°C for 1h to enhance W 18 o 49 Contact with the FTO substrate.

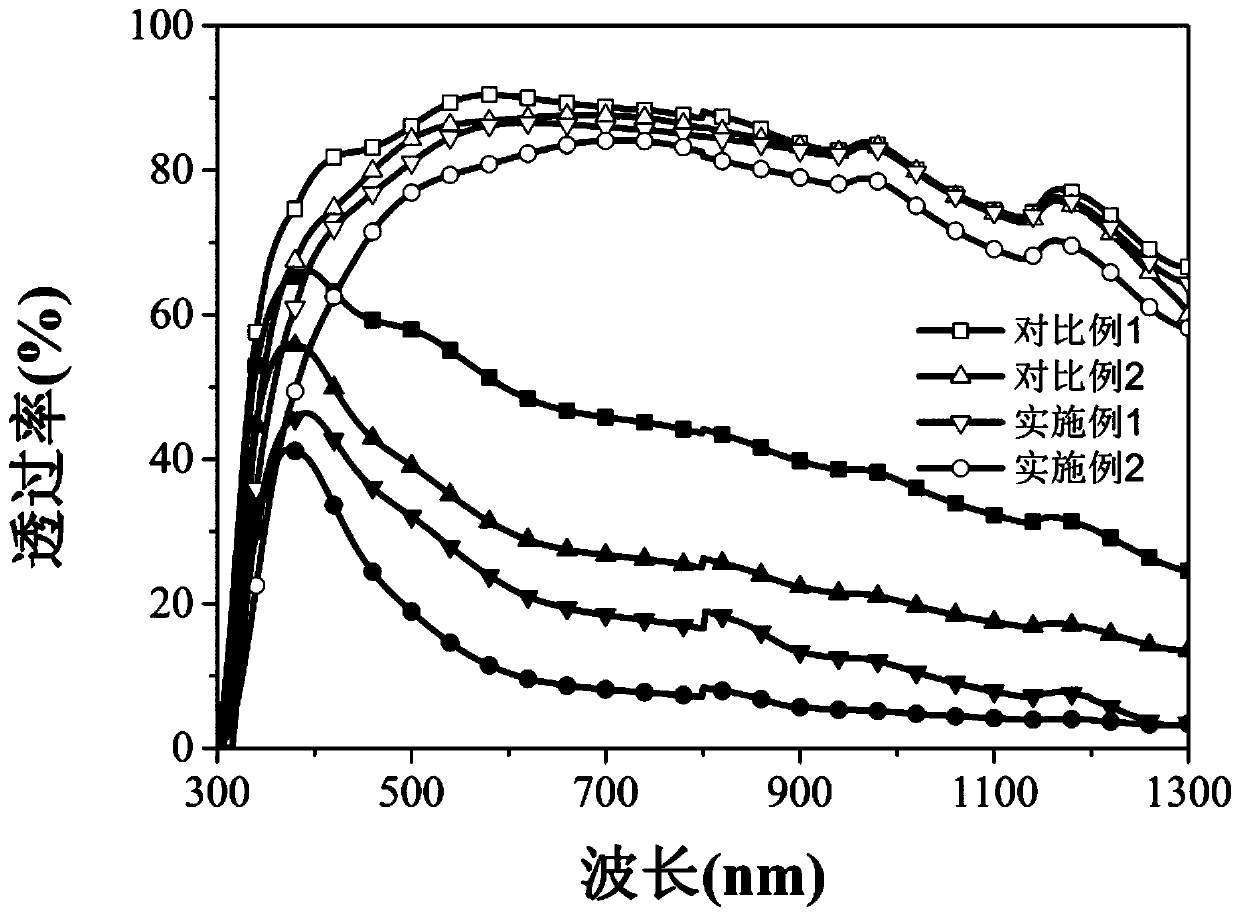

[0042] The electrochromic test was carried out on CHI 600D electrochemical workstation and Cary 5000 UV-visible spectrophotometer, W 18 o...

Embodiment 2

[0044] Preparation W 18 o 49 method, the steps are as follows:

[0045] (1) Clean the FTO glass sheet with acetone, isopropanol, ethanol;

[0046] (2) Dissolve 1.0 g of oxalic acid in 30 ml of ethanol, stir for 10 min to obtain a clear solution;

[0047] (3) Add 0.1g WCl 6 Dissolve in the clear solution and stir for 20 minutes to obtain a transparent yellow precursor solution;

[0048] (4) Put the cleaned FTO glass sheet vertically into the reaction kettle, add the precursor solution filtered through a 0.22 μm organic membrane and cover the glass sheet, and obtain W after solvothermal reaction at 180°C for 10 hours. 18 o 49 - FTO glass samples;

[0049] (5) will W 18 o 49 -FTO glass samples were washed with ethanol and water successively, dried at 60°C, and heat-treated at 200°C for 1h to enhance W 18 o 49 Contact with the FTO substrate.

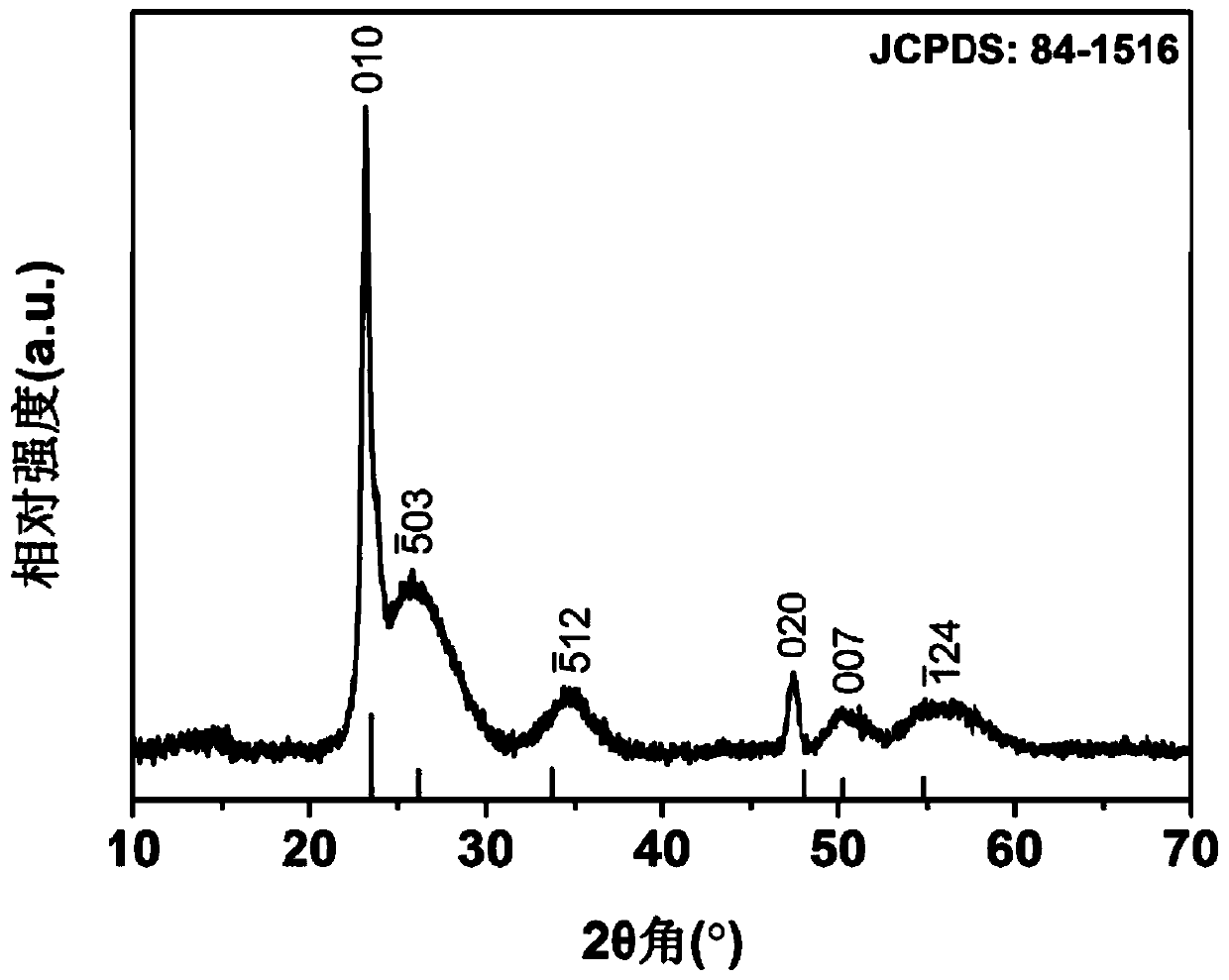

[0050] Scrape a small amount of W from the substrate 18 o 49 Powder, after testing, the X-ray diffraction pattern is as follow...

Embodiment 3

[0052] Preparation W 18 o 49 method, the steps are as follows:

[0053] (1) Clean the FTO glass sheet with acetone, isopropanol, ethanol;

[0054] (2) Dissolve 0.5g oxalic acid in 30ml ethanol, stir for 10min to obtain a clear solution;

[0055] (3) Add 0.2gWCl 6 Dissolve in the clear solution and stir for 20 minutes to obtain a transparent yellow precursor solution;

[0056] (4) Put the cleaned FTO glass sheet vertically into the reaction kettle, add the precursor solution filtered through a 0.22 μm organic membrane and cover the glass sheet, and obtain W after solvothermal reaction at 180°C for 10 hours. 18 o 49 - FTO glass samples;

[0057] (5) will W 18 o 49 -FTO glass samples were washed with ethanol and water successively, dried at 60°C, and heat-treated at 200°C for 1h to enhance W 18 o 49 Contact with the FTO substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com