The preparation method of cyclohexene

A technology of cyclohexene and dicyclohexyl ether, applied in the field of preparation of cyclohexene, can solve the problems of many by-products, low conversion rate, complicated separation process, etc., and achieve the effect of reducing combustion emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

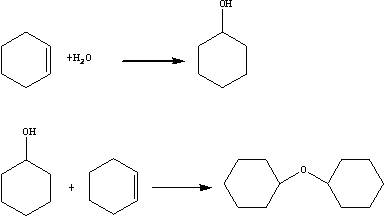

Image

Examples

preparation example Construction

[0029] The preparation method of cyclohexene in an embodiment includes the following steps S110 to S140:

[0030] S110, provide dicyclohexyl ether.

[0031] In this embodiment, dicyclohexyl ether is prepared by the following method:

[0032] (1) Provide fuel oil, which is produced during the process of preparing cyclohexanol by cyclohexene hydration.

[0033] Specifically, the fuel oil contains cyclohexane, methylcyclopentane, cyclohexene, cyclohexanol and dicyclohexyl ether.

[0034] (2) The above fuel oil is rectified and purified to obtain dicyclohexyl ether.

[0035] Specifically, the above-mentioned fuel oil is subjected to atmospheric distillation and negative pressure distillation in sequence to obtain dicyclohexyl ether.

[0036] Further, the conditions of atmospheric distillation are: the top temperature is 70°C to 90°C, and the reflux ratio is 3 to 10:1.

[0037] The conditions of negative pressure distillation are: pressure 0.1KPa~5KPa, reflux ratio 3~10:1, top temperature 80℃~1...

Embodiment 1

[0053] The fuel oil containing 1% methylcyclopentane, 15% cyclohexane, 5% cyclohexene, 35% cyclohexanol and 44% dicyclohexyl ether is subjected to atmospheric distillation and negative pressure successively Rectification, atmospheric distillation to obtain light fraction fractions, negative pressure rectification to obtain cyclohexanol fraction and dicyclohexyl ether fraction respectively. Among them, the content of cyclohexanol in the cyclohexanol fraction> 99.5%, the content of dicyclohexyl ether in the dicyclohexyl ether fraction is 87%.

[0054] The above-mentioned dicyclohexyl ether distillation section was reacted in a fixed-bed reactor equipped with potassium carbonate catalyst at a reaction temperature of 280°C and a space velocity of 0.2h -1 , The reaction pressure is 0MPa, and the cracked product is obtained.

[0055] The above cracked product is cooled to below 60°C, oil-water separation is carried out, and the oil phase is taken for rectification to obtain cyclohexene d...

Embodiment 2

[0067] The fuel oil containing 1% methylcyclopentane, 15% cyclohexane, 5% cyclohexene, 35% cyclohexanol and 44% dicyclohexyl ether is subjected to atmospheric distillation and negative pressure in sequence Rectification, atmospheric distillation to obtain light fraction fraction, negative pressure rectification to obtain cyclohexanol fraction and dicyclohexyl ether fraction respectively. Among them, the content of cyclohexanol in the cyclohexanol fraction> 99.5%, the content of dicyclohexyl ether in the dicyclohexyl ether fraction is 87%.

[0068] The above-mentioned dicyclohexyl ether fraction was reacted in a fixed-bed reactor equipped with a 4A molecular sieve catalyst at a reaction temperature of 330°C and a space velocity of 0.3h -1 , The reaction pressure is 0.2MPa, and the cracked product is obtained.

[0069] The above cracked product is cooled to below 60°C, oil-water separation is carried out, and the oil phase is taken for rectification to obtain cyclohexene distillation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com