Method for synthesizing nitric acid

A synthesis method and technology of nitric acid, applied in the science and engineering fields of nanomaterials and energy environment, can solve the problems of low utilization rate of specific surface atoms and unspecified specific uses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The embodiment of the invention discloses a kind of synthetic method of nitric acid, comprising:

[0031] Will Fu Pit WO 3 The nanosheet material is mixed with water, a mixed gas of nitrogen and oxygen is passed into the obtained water phase, and a photocatalytic reaction is carried out under light conditions to obtain nitric acid.

[0032] The synthetic method of nitric acid provided by the application is to enrich pit WO 3 Nanosheet materials as photocatalysts due to pit-rich WO 3 The nanosheet material has a special morphology, which provides active sites for photocatalytic nitrogen fixation, and ultimately improves the reactivity, and the method is simple, mild, and easy for large-scale production.

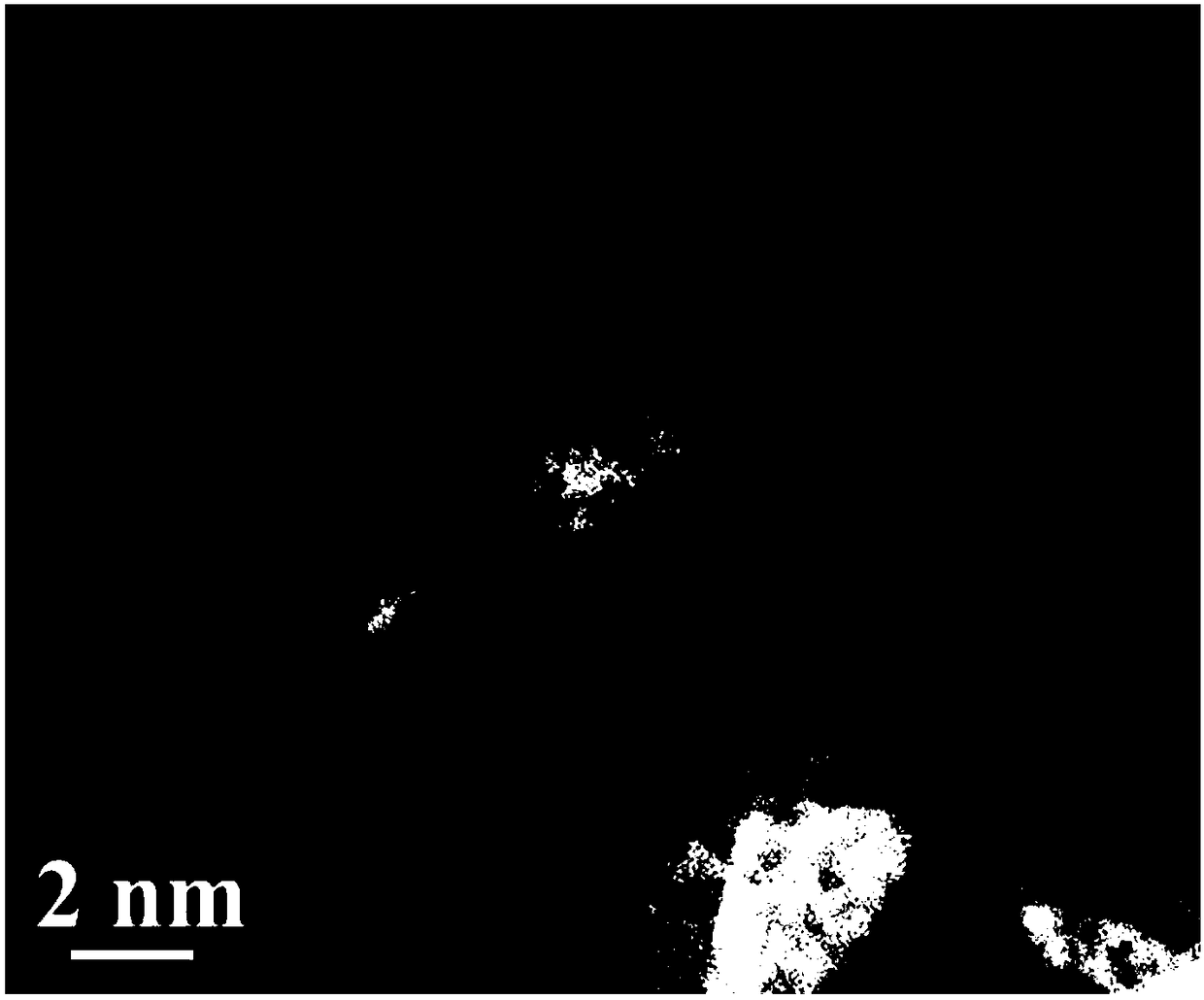

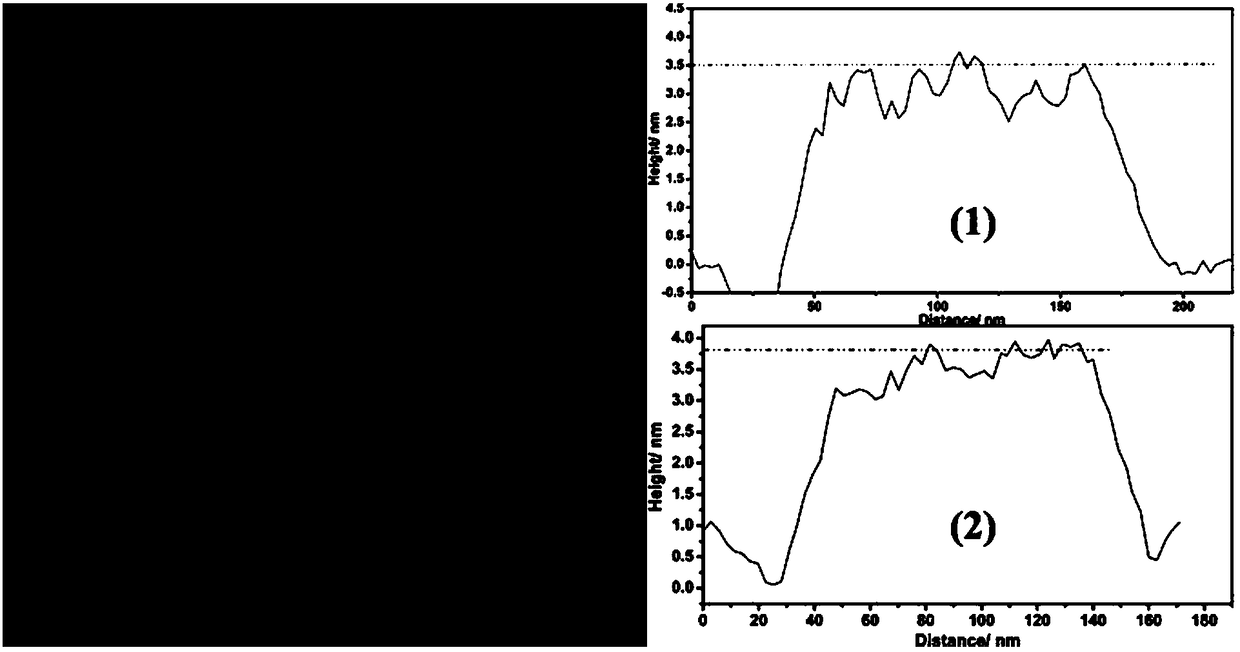

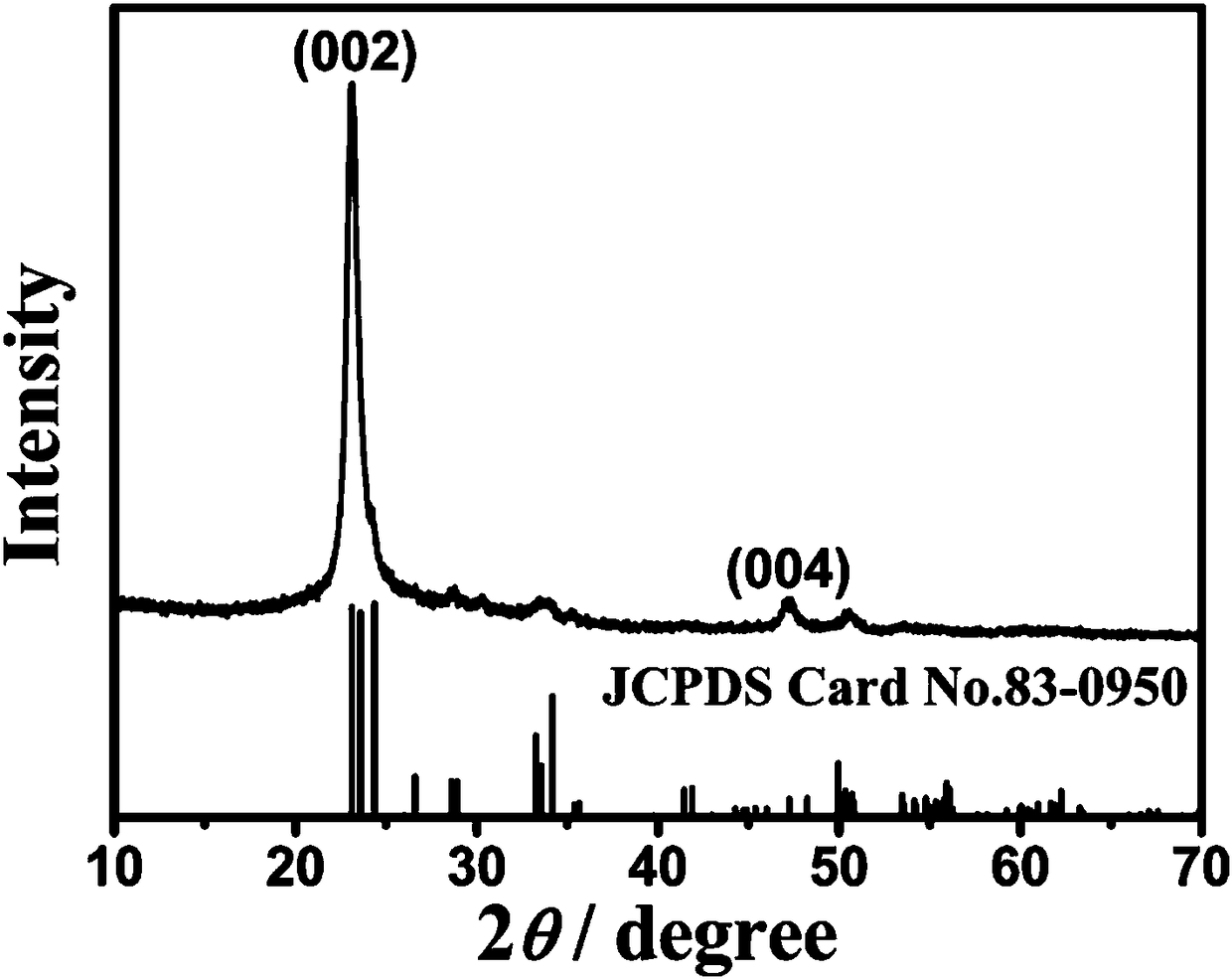

[0033] In the process of synthesizing nitric acid, the photocatalyst that this application adopts is rich pit WO 3 Nanosheet material, the material has unique pits rich in unsaturated bonds, the size and aperture of the pits are 1-4nm, the sheet size is 200-500nm, the ...

Embodiment 1

[0052] Accurately weigh 0.4g of analytically pure sodium tungstate dihydrate, add it to 300ml of 4.8mol / L nitric acid, stir at 20°C for 72h; centrifuge the obtained light yellow suspension, and then wash it with distilled water Wash 5 times; the product obtained was dried overnight at room temperature, and the sample obtained at this time was WO 3 2H 2 O; Accurately weigh 10mg WO 3 2H 2 O was dispersed in 10ml of distilled water, then sonicated in an ice-water bath for 3h, and then the light yellow suspension was centrifuged at 5000rmp for 10min, and then the supernatant was carefully sucked up with a pipette, and the sucked supernatant was centrifuged at 14000rmp for 15min , get WO 3 2H 2 O ultrathin; WO will be obtained 3 2H 2 O ultrathin slices were dried overnight at room temperature, and finally the WO 3 2H 2 O ultrathin flakes were topologically transformed at 400°C for 30 minutes, and the yellow-green powder was taken out after cooling, which was the target WO ...

Embodiment 2

[0056] Accurately weigh 0.4g of analytically pure sodium tungstate dihydrate, add it to 300ml of 4.8mol / L nitric acid, stir at 20°C for 72h; centrifuge the obtained light yellow suspension, and then wash it with distilled water Wash 5 times; the product obtained was dried overnight at room temperature, and the sample obtained at this time was WO 3 2H 2 O; Accurately weigh 20mg WO 3 2H 2 O was dispersed in 100ml of distilled water, then ultrasonicated in an ice-water bath for 5h, and then the light yellow suspension was centrifuged at 5000rmp for 10min, and then the supernatant was carefully sucked up with a pipette, and the sucked supernatant was centrifuged at 14000rmp for 15min , get WO 3 2H 2 O ultrathin; WO will be obtained 3 2H 2 O ultrathin slices were dried overnight at room temperature, and finally the WO 3 2H 2 O ultrathin flakes were topologically transformed at 400°C for 30 minutes, and the yellow-green powder was taken out after cooling, which was the targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com