Metallographic etchant, metallographic sample corrosion method and metallographic structure display method

A technology of metallographic structure display and metallographic sample, applied in the field of metallographic etchant and metallographic structure display, can solve the problems of difficult control of corrosion degree, cumbersome methods and steps, poor effect, etc., so as to improve corrosion efficiency and surface metallographic appearance. The effect of the microtissue display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the present invention, the technical solutions of the present invention will be described in detail below in conjunction with specific examples.

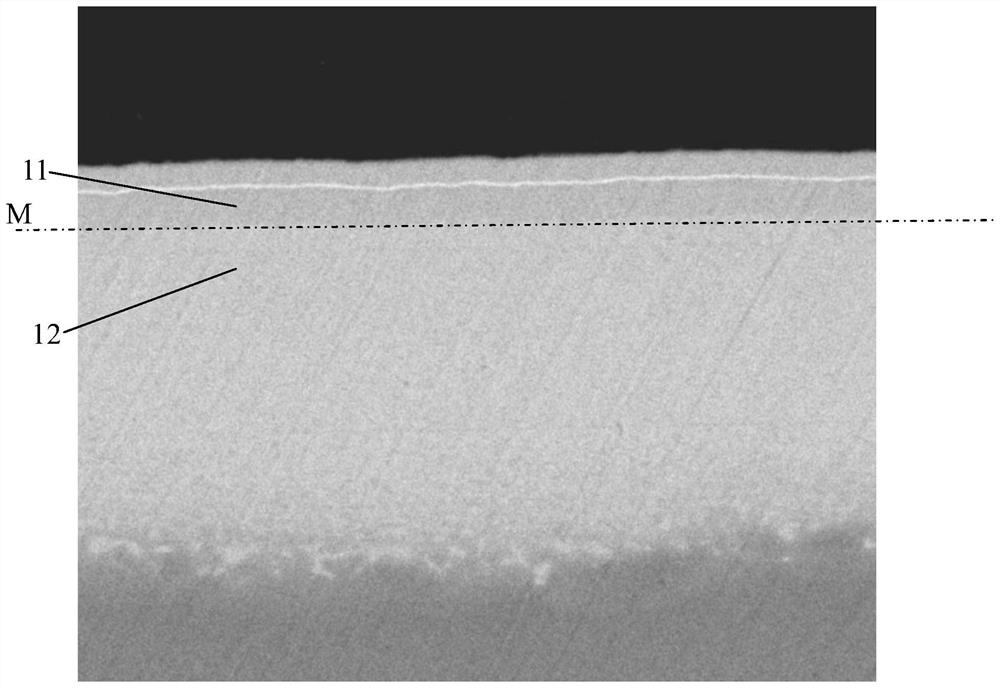

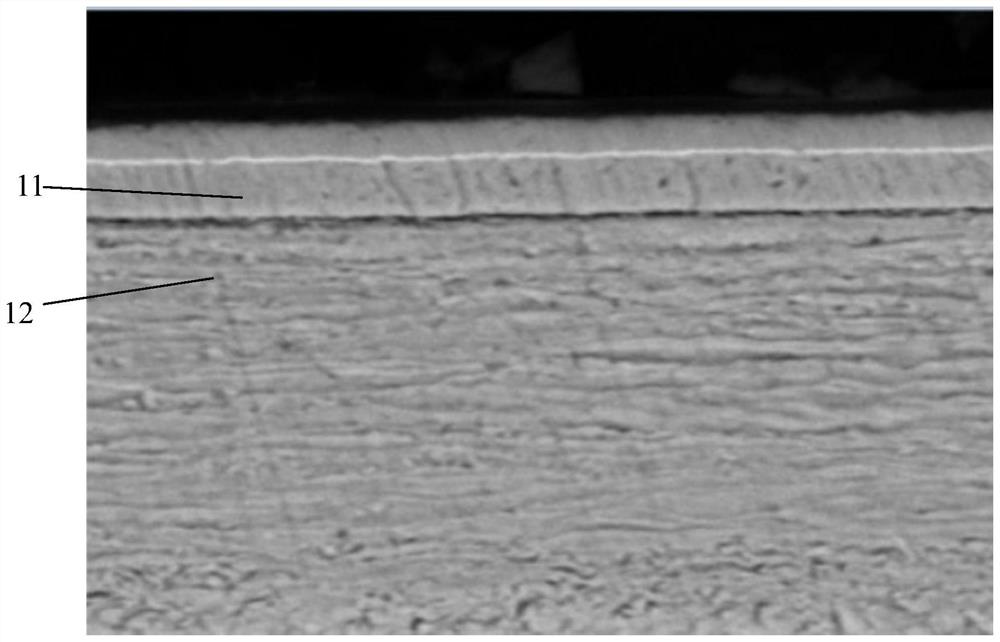

[0020] Provide palladium and palladium alloy metallographic samples, such as figure 1 As shown, the metallographic sample includes a palladium alloy layer 12 and a palladium layer 11 plated on the palladium alloy layer 12, and the dotted line M is the dividing line between the two layers, and the dividing line is not obvious in this real object. Then, mechanically grind and polish the metallographic sample first, soak the mechanically polished metallographic sample in a metallographic etchant for 30s~60s, rinse with running water for 5s~10s, and then bake it in an oven at 50°C After 3min to 5min, the corroded palladium and palladium alloy metallographic samples are obtained. Finally, high-magnification optical microscope and electronic scanning electron microsco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com