High order Raman inhibition method based on polarization maintaining optical fiber 45-degree dislocation welding technology

A dislocation fusion splicing, polarization maintaining fiber technology, applied in the coupling of optical waveguides, optics, light guides, etc., can solve the problems of high insertion loss, complex preparation process, and applications that have not been publicly reported, and achieve low insertion loss, low cost, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

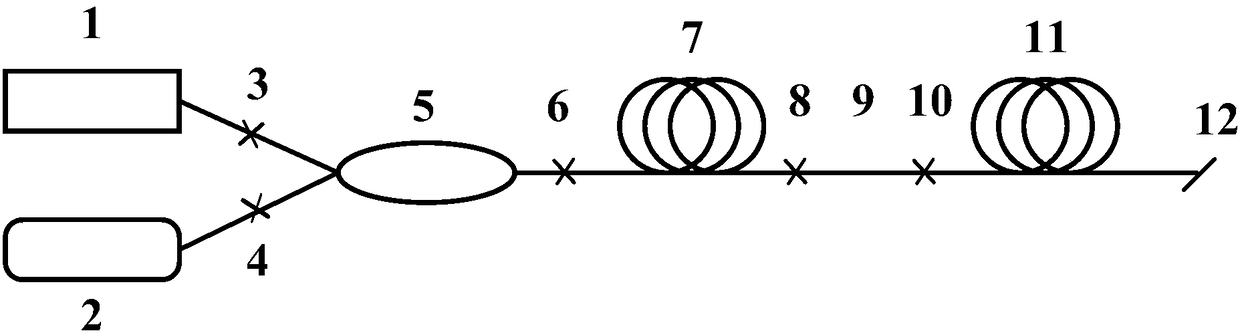

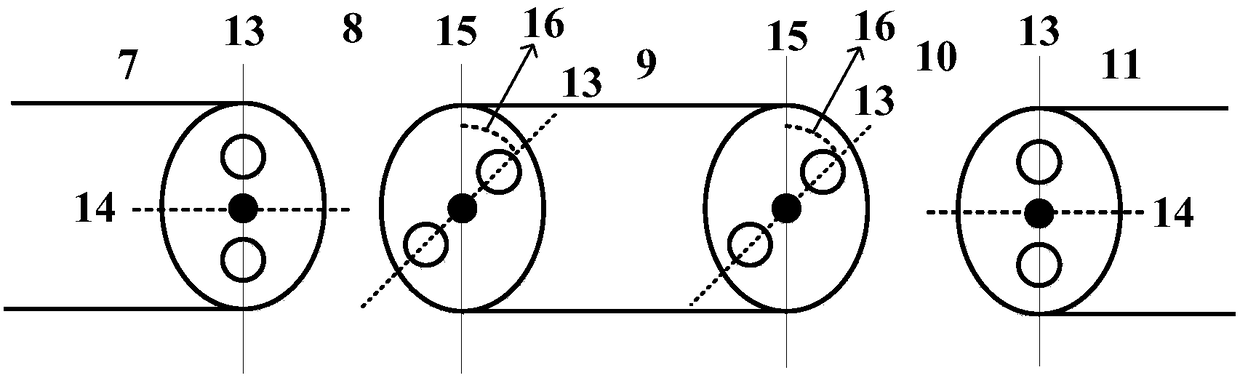

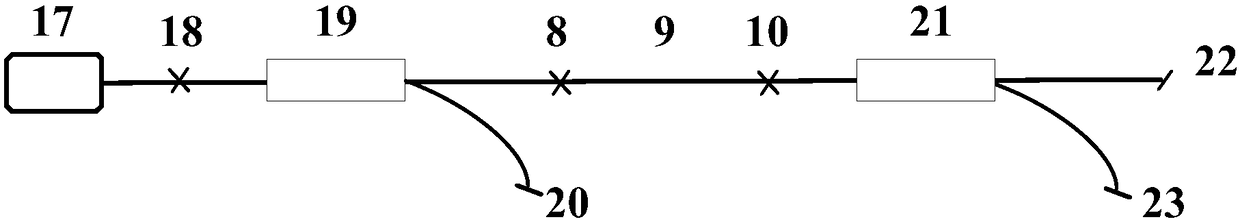

[0024] figure 1 It is a structural schematic diagram of a specific embodiment of the present invention. In the linearly polarized Raman fiber laser, the Raman gain is relatively low when the pump wave and the Stokes wave are orthogonally polarized in the Raman gain spectrum. Through three sections of polarization-maintaining passive The two 45-degree dislocation fusion splices between the fibers realize the polarization rotation function with wavelength selection characteristics, so that the polarization directions of the pump light and the low-order Raman light remain unchanged, while the polarization direction of the high-order Raman light is orthogonal to the pump light. Thereby suppressing the gain of higher-order Raman.

[0025] refer to figure 1 A linearly polarized Raman fiber laser includes a linearly polarized pump source 1, a linearly polarized signal source 2, a polarization-maintaining passive fiber and a wavelength division multiplexer 5, and the polarization-mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com