Medical instrument disinfecting and sterilizing method

A medical equipment, disinfection and sterilization technology, applied in the field of medical wastewater treatment and medical equipment, can solve the problems of long ultraviolet disinfection and disinfection time, high requirements for disinfectant, water pollution, etc., achieve comprehensive disinfection and sterilization operations, avoid soaking and non-flowing , Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

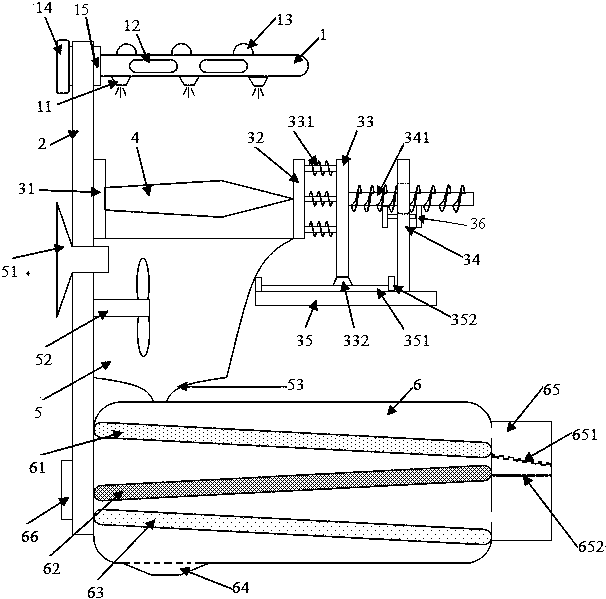

[0033] Such as figure 1 Shown: a medical device disinfection and sterilization method, the medical device disinfection and sterilization method adopts a medical device disinfection and sterilization device, and the medical device disinfection and sterilization device includes a disinfection and sterilization component, a clamping component and a waste water treatment part.

[0034] The disinfection and sterilization parts include a horizontal shaft, a disinfectant nozzle, an infrared drying part, an ultraviolet disinfection part, a motor and a bearing; the left end of the horizontal shaft is a round shaft and the right end is a square shaft, and the left end passes through the bearing and The vertical bracket of the component is rotatably connected, and a motor is provided at the leftmost end of the horizontal rotation shaft to drive the rotation of the horizontal rotation shaft. Three disinfectants are respectively provided on three surfaces of the four sides of the square sh...

Embodiment 2

[0051] A medical device disinfection and sterilization method, the medical device disinfection and sterilization method adopts a medical device disinfection and sterilization device, and the medical device disinfection and sterilization device includes a disinfection and sterilization component, a clamping component and a waste water treatment component.

[0052] The disinfection and sterilization parts include a horizontal shaft, a disinfectant nozzle, an infrared drying part, an ultraviolet disinfection part, a motor and a bearing; the left end of the horizontal shaft is a round shaft and the right end is a square shaft, and the left end passes through the bearing and The vertical brackets of the components are rotatably connected, and a motor is provided at the leftmost end of the horizontal rotation shaft to drive the rotation of the horizontal rotation shaft. Five disinfectants are respectively provided on three surfaces of the four sides of the square shaft at the right en...

Embodiment 3

[0069] A medical device disinfection and sterilization method, the medical device disinfection and sterilization method adopts a medical device disinfection and sterilization device, and the medical device disinfection and sterilization device includes a disinfection and sterilization component, a clamping component and a waste water treatment component.

[0070] The disinfection and sterilization parts include a horizontal shaft, a disinfectant nozzle, an infrared drying part, an ultraviolet disinfection part, a motor and a bearing; the left end of the horizontal shaft is a round shaft and the right end is a square shaft, and the left end passes through the bearing and The vertical brackets of the components are rotatably connected, and a motor is provided at the leftmost end of the horizontal rotation shaft to drive the rotation of the horizontal rotation shaft. Six disinfectants are respectively provided on three of the four sides of the square shaft at the right end of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com