High-concentration emulsion wastewater treatment technology and device

A wastewater treatment and emulsification technology, applied in water/sewage treatment, flotation water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problems of high maintenance cost, low durability, etc. Equipment requirements are simple and easy to control the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

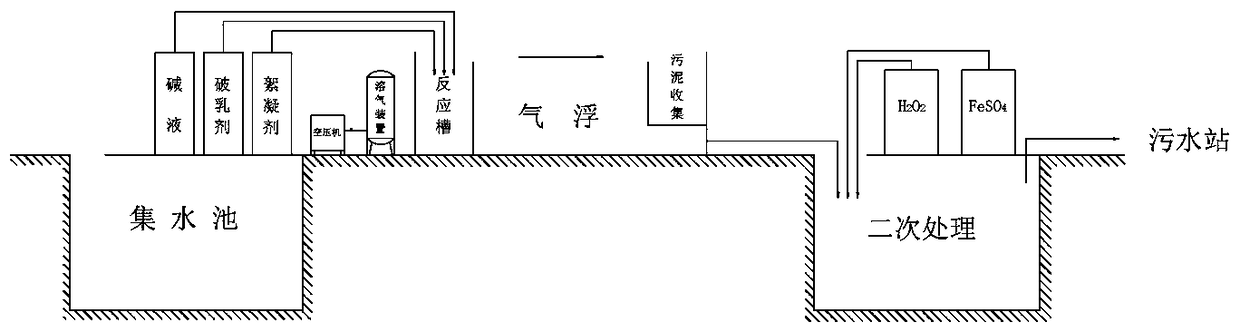

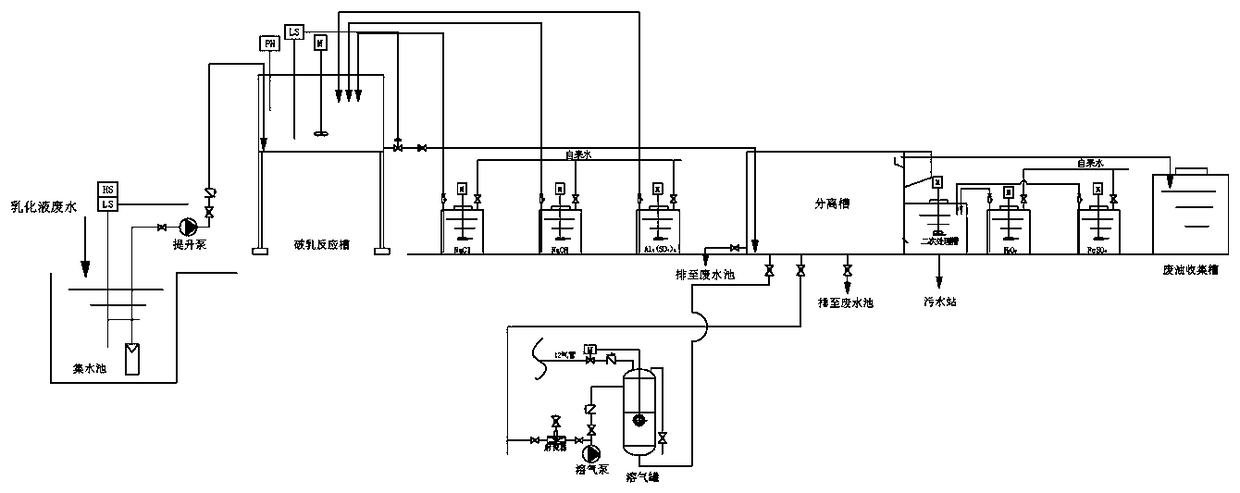

[0023] like figure 1 As shown, a high concentration emulsion wastewater treatment process, high concentration refers to the emulsion wastewater whose COD value exceeds 100000mg / L, including the following steps:

[0024] Step 1), the waste emulsion is collected, and the air is continuously injected, and the air is provided by an air compressor;

[0025] Step 2), adjust the pH value, pump the waste emulsion into the reaction tank, add lye, the lye is NaOH solution with a mass fraction of 15%, start the stirring device, and adjust the pH of the waste emulsion to 6~9;

[0026] Step 3), demulsification and flocculation, after the pH of the waste emulsion is adjusted, add a demulsification flocculant to the waste emulsion, set the stirring device to stir for 5 minutes and then stop stirring, the temperature of the waste emulsion is maintained at 30~45°C, The waste emulsion enters the separation tank; the demulsifier and flocculant are NaCl and Al respectively 2 (SO 4 ) 3 , the m...

Embodiment 2

[0033] like figure 1 As shown, a high concentration emulsion wastewater treatment process, high concentration refers to the emulsion wastewater whose COD value exceeds 100000mg / L, including the following steps:

[0034] Step 1), the waste emulsion is collected, and the air is continuously injected, and the air is provided by an air compressor;

[0035] Step 2), adjust the pH value, pump the waste emulsion into the reaction tank, add lye, the lye is NaOH solution with a mass fraction of 15%, start the stirring device, and adjust the pH of the waste emulsion to 6~9;

[0036] Step 3), demulsification and flocculation, after the pH of the waste emulsion is adjusted, add a demulsification flocculant to the waste emulsion, set the stirring device to stir for 5 minutes and then stop stirring, the temperature of the waste emulsion is maintained at 30~45°C, The waste emulsion enters the separation tank; the demulsifier and flocculant are NaCl and Al respectively 2 (SO 4 ) 3 , the m...

Embodiment 3

[0043] like figure 1 As shown, a high concentration emulsion wastewater treatment process, high concentration refers to the emulsion wastewater whose COD value exceeds 100000mg / L, including the following steps:

[0044] Step 1), the waste emulsion is collected, and the air is continuously injected, and the air is provided by an air compressor;

[0045]Step 2), adjust the pH value, pump the waste emulsion into the reaction tank, add lye, the lye is NaOH solution with a mass fraction of 15%, start the stirring device, and adjust the pH of the waste emulsion to 6~9;

[0046] Step 3), demulsification and flocculation, after the pH of the waste emulsion is adjusted, add a demulsification flocculant to the waste emulsion, set the stirring device to stir for 10 minutes and then stop stirring, the temperature of the waste emulsion is maintained at 30~45°C, The waste emulsion enters the separation tank; the demulsifier and flocculant are NaCl and Al respectively 2 (SO 4 ) 3 , the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com