Method for continuously preparing fluoroethylene carbonate and/or vinylene carbonate by gas phase

A technology of fluoroethylene carbonate and vinylene carbonate, which is applied in the field of gas-phase continuous preparation of fluoroethylene carbonate, can solve problems such as environmental pollution, difficult reaction control, and difficult acquisition of organic raw materials, and achieves easy continuous process and easy reaction , easily accessible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

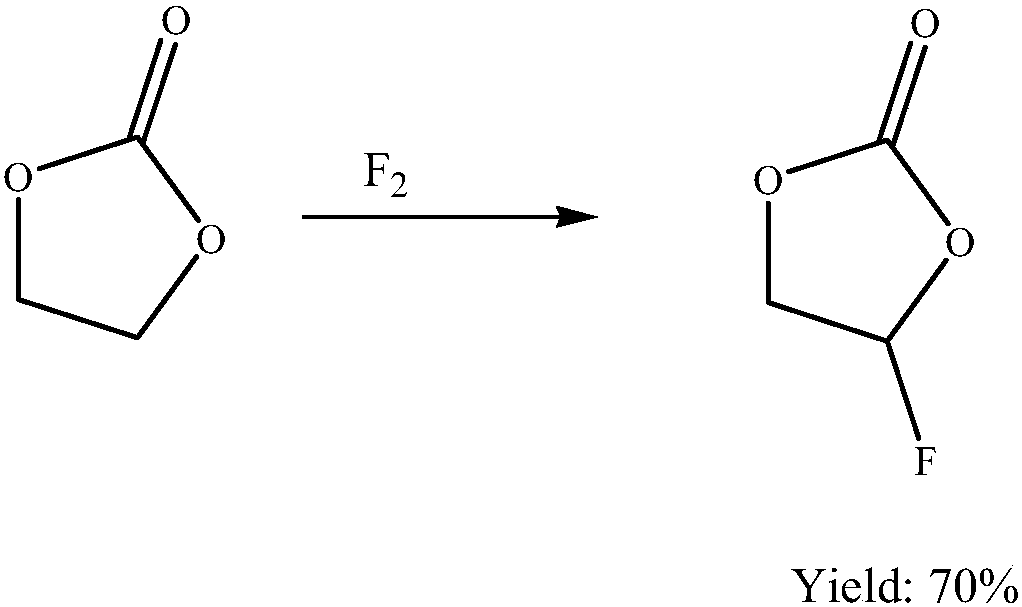

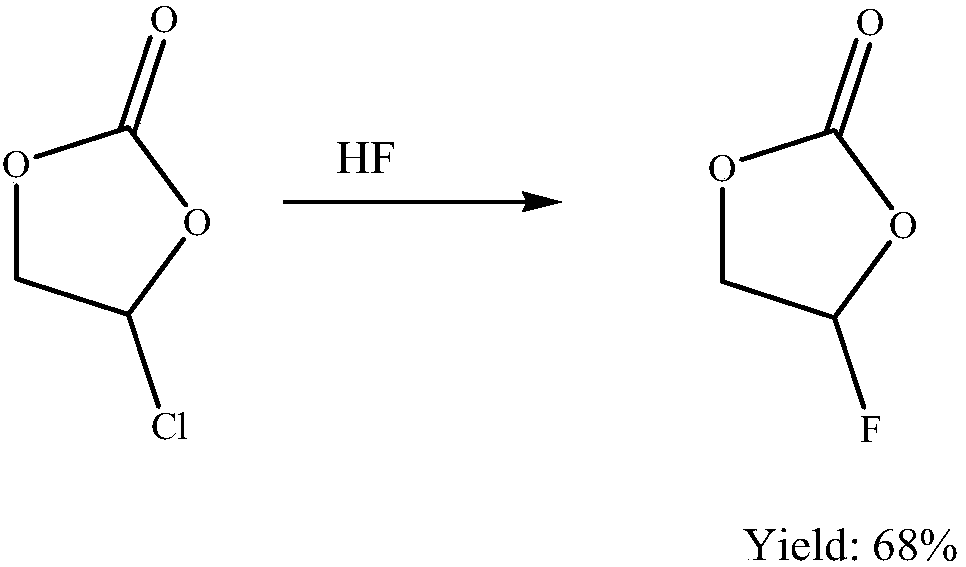

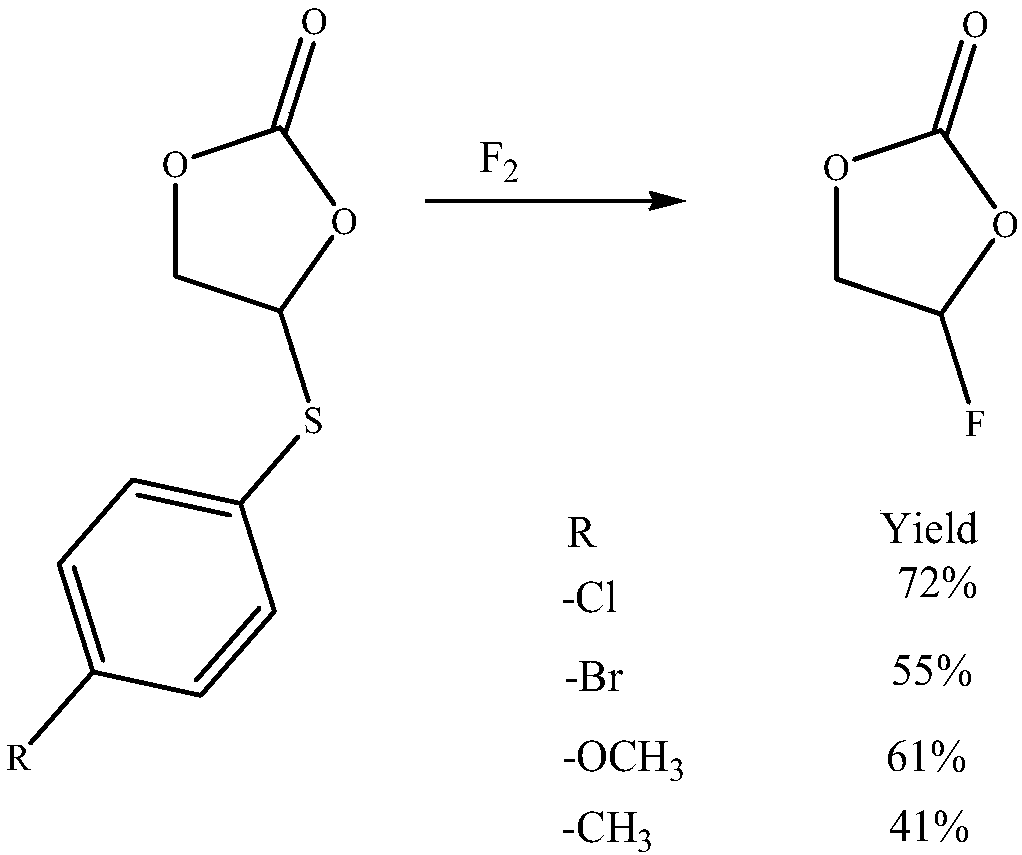

Method used

Image

Examples

Embodiment 1

[0030] 10 ml of commercially available activated carbon (Shirasagi C2x7 / 12 activated carbon, Osaka Gas Chemicals Co. Ltd.) was charged into a tubular reactor made of Inconium alloy with an inner diameter of 1 / 2 inch and a length of 30 cm. The reaction conditions are: the reaction temperature is raised to 160°C, the molar ratio of anhydrous hydrogen fluoride to chloroethylene carbonate is 10:1, the contact time is 10s, and the reaction pressure is 0.1MPa. After running for 10 hours, the reaction product was separated by heating to remove HF and HCl, then condensed, and the liquid organic phase was taken for GC analysis. The reaction result is: the conversion rate of chloroethylene carbonate is 97.71%, the selectivity of fluoroethylene carbonate is 55.8%, the selectivity of vinylene carbonate is 15.9%, the rest is fluoroacetaldehyde, chloroacetaldehyde , acetic acid and other by-products.

[0031] The above organic phase was rectified to obtain fluoroethylene carbonate and viny...

Embodiment 2

[0033] Fill 10 milliliters of fluorination catalyst FeF prepared by the above-mentioned method in the tubular reactor made of Incon alloy with internal diameter 1 / 2 inch, long 30cm 3 . The reaction conditions are: the reaction temperature is raised to 160°C, the molar ratio of anhydrous hydrogen fluoride to chloroethylene carbonate is 10:1, the contact time is 10s, and the reaction pressure is 0.1MPa. After running for 10 hours, the reaction product was separated by heating to remove HF and HCl, then condensed, and the liquid organic phase was taken for GC analysis. The reaction result is: the conversion rate of chloroethylene carbonate is 100%, the selectivity of fluoroethylene carbonate is 81.0%, the selectivity of vinylene carbonate is 12.7%, the rest is fluoroacetaldehyde, chloroacetaldehyde , acetic acid and other by-products.

[0034] The above organic phase was rectified to obtain fluoroethylene carbonate and vinylene carbonate. The boiling point of fluoroethylene car...

Embodiment 3

[0036] Fill 10 milliliters of fluorination catalyst FeF prepared by the above-mentioned method in the tubular reactor made of Incon alloy with internal diameter 1 / 2 inch, long 30cm 3 . The reaction conditions are: the reaction temperature is raised to 200°C, the molar ratio of anhydrous hydrogen fluoride to chloroethylene carbonate is 10:1, the contact time is 10s, and the reaction pressure is 0.1MPa. After running for 10 hours, the reaction product was separated by heating to remove HF and HCl, then condensed, and the liquid organic phase was taken for GC analysis. The reaction result is: the conversion rate of chloroethylene carbonate is 100%, the selectivity of fluoroethylene carbonate is 56.3%, the selectivity of vinylene carbonate is 32.9%, the rest is fluoroacetaldehyde, chloroacetaldehyde , acetic acid and other by-products.

[0037] The above organic phase was rectified to obtain fluoroethylene carbonate and vinylene carbonate. The boiling point of fluoroethylene car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com