A kind of polyvinyl alcohol sulfonate and its synthesis method, printing hydrophilic plate and application and printing plate

A technology of polyvinyl alcohol sulfonate and polyvinyl alcohol, which is applied in the printing plate field to achieve the effect of clean surface, good hydrophilic effect and high printing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

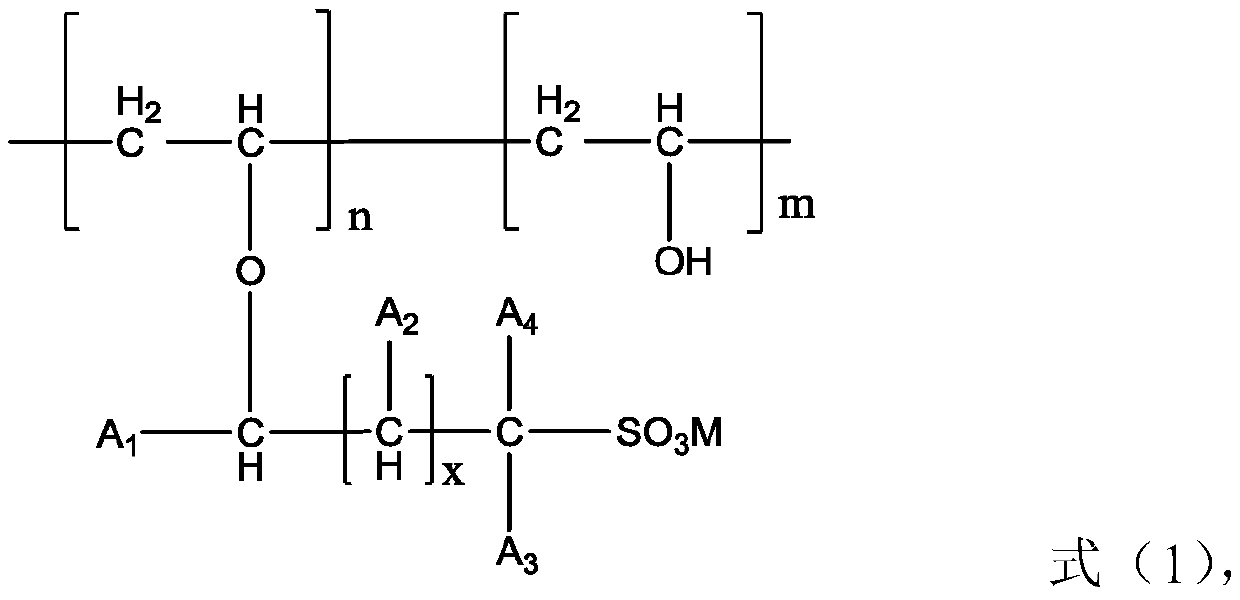

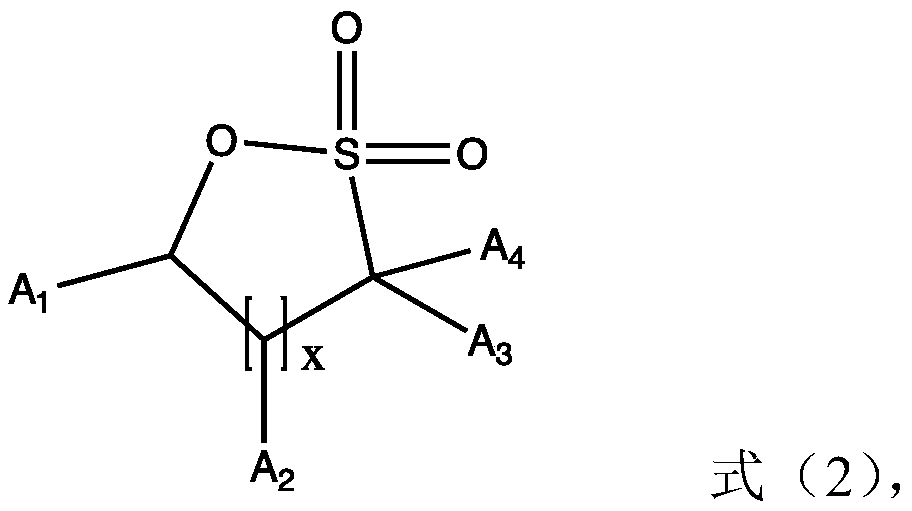

[0030] According to a preferred embodiment of the present invention, the polyvinyl alcohol sulfonate can be synthesized by the following method: the polyvinyl alcohol sulfonate is an etherification product of polyvinyl alcohol and sultone.

[0031] Preferably, the sultone is selected from 1,3-propane sultone, 1,4-propane sultone, 1-methyl-1,3-propane sultone, 1,1- Dimethyl-1,3-propane sultone, 1-ethyl-1,3-propane sultone, 1,2-dimethyl-1,3-propane sultone, 1,3 -Dimethyl-1,3-propane sultone, 1-propenyl-1,3-propane sultone, 1-methyl-2-ethyl-1,3-propane sultone, 1-Methyl-1,4-butane sultone, 1-methyl-1,4-butane sultone, 1-propenyl-1,4-butane sultone and 1,5-pentane At least one of the sultones. More preferably, the sultone is selected from 1,3-propane sultone, 1-methyl-1,3-propane sultone, 1,1-dimethyl-1,3-propane sultone At least one of acid lactone, 1-ethyl-1,3-propane sultone, 1,2-dimethyl-1,3-propane sultone and 1,4-propane sultone kind.

[0032] In the present invention, ...

Embodiment 1

[0090] This example illustrates the preparation of polyvinyl alcohol sulfonates of the present invention.

[0091] Dissolve 22g of polyvinyl alcohol (Ningxia Dadi Chemical Co., Ltd. 1799) in 200mL of dimethylformamide (DMF), add 5.7g of sodium metal after chopping, and mix at room temperature for 0.5h;

[0092] Then dropwise add 1,3-propane sultone (Bailingwei Technology Co., Ltd.) in dimethylformamide solution (1,3-propane sultone 30.5g, dimethylformamide 300mL), polyvinyl alcohol: The weight ratio of 1,3-propane sultone is 0.72:1, after about 1 hour, the reaction mixture is obtained;

[0093] The reaction mixture was pre-reacted at room temperature for 1 hour, and then heated to 70°C for etherification reaction for 3 hours;

[0094] The product obtained after the etherification reaction is completed is spray-dried to obtain a solid powder.

[0095] The solid powder is subjected to infrared spectrum analysis, and the wave number in the spectrum is 3340cm -1 The place is th...

Embodiment 2

[0098] This example illustrates the preparation of polyvinyl alcohol sulfonates of the present invention.

[0099] 11g of polyvinyl alcohol (Ningxia Dadi Chemical Co., Ltd. 1899) was dissolved in 100mL of dioxane, and a total of 6g of sodium hydride (dispersed in mineral oil, wherein the concentration of sodium hydride was 60% by weight) was slowly added in three batches , mixed at room temperature for 1h;

[0100] Then a dioxane solution of 1-methyl-1,3-propane sultone (Sigma-Aldrich) was added dropwise (20.4 g of 1-methyl-1,3-propane sultone, dioxane 20mL), the weight ratio of polyvinyl alcohol:1-methyl-1,3-propane sultone is 0.54:1, after about 1h, the reaction mixture is obtained;

[0101] The reaction mixture was pre-reacted at room temperature for 1.2 hours, and then heated to 75°C for etherification reaction for 2 hours;

[0102] The product obtained after the etherification reaction is completed is spray-dried to obtain a solid powder.

[0103] The solid powder is s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com