Clostridium acetobutylicum and application thereof

A technology of Clostridium acetobutylicum and butanol, which is applied in the direction of bacteria, microorganisms, biofuels, etc., and can solve the problem of weak inhibitory ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Clostridium acetobutylicum LJ4 bacterial strain is isolated and screened in a screening plate containing furfural, 5-hydroxymethylfurfural, ferulic acid, p-coumaric acid, and vanillin each 0.5g / L

[0034] Weigh 1g of the soil sample taken from Pearl Spring soil, dilute it with normal saline, and pipette 200μL onto a plate containing 0.5g / L each of furfural, 5-hydroxymethylfurfural, ferulic acid, p-coumaric acid, and vanillin , and cultured anaerobically at 37°C for 192h. The grown colonies were streaked and purified for 5 generations, and the strain Clostridiumacetobutylicum LJ4 with strong tolerance to lignocellulose hydrolyzate inhibitors was screened out.

[0035] The medium formula of the above screening plate is NaCl 1g / L, K 2 HPO 4 0.75g / L, KH 2 PO 4 0.75g / L, yeast powder 3g / L, CaCl 2 2H 2 O 0.015g / L, FeCl 2 4H 2 O 1.5g / L, KCl 0.3g / L, furfural, 5-hydroxymethylfurfural, ferulic acid, p-coumaric acid, vanillin 0.5g / L each, adjust the pH to 4.5-6....

Embodiment 2

[0036] Example 2 Identification of Clostridium acetobutylicum LJ4 and its growth characteristics

[0037] 16S rDNA identification of LJ4:

[0038]Using primers 27F: 5'-AGAGTTTGATCCTGGCTCAG-3' and 1492R: 5'-TACCTTGTTACGACTT-3' to amplify the 16S rDNA of strain LJ4, connect it to the cloning vector pMD19T by T / A cloning, and construct the recombinant cloning vector pMD19T-16S, Transform it into the cloning host strain Escherich coli DH5α to obtain the recombinant microorganism Escherichcoli DH5α (pMD19T-16S), sequence the exogenous fragment of the obtained recombinant microorganism, compare the 16S rDNA sequence with the NCBI database, and identify the strain LJ4 at the molecular level For the genus Clostridium acetobutylicum, the nucleotide sequence of its 16SrDNA is shown in SEQ ID NO: 1 in the sequence listing.

[0039] Growth and metabolic characteristics of LJ4:

[0040] Strain LJ4 can grow well at 37°C, grow well at pH 4.5-6.5, and grow best at pH 5.5. LJ4 is in the log...

Embodiment 3

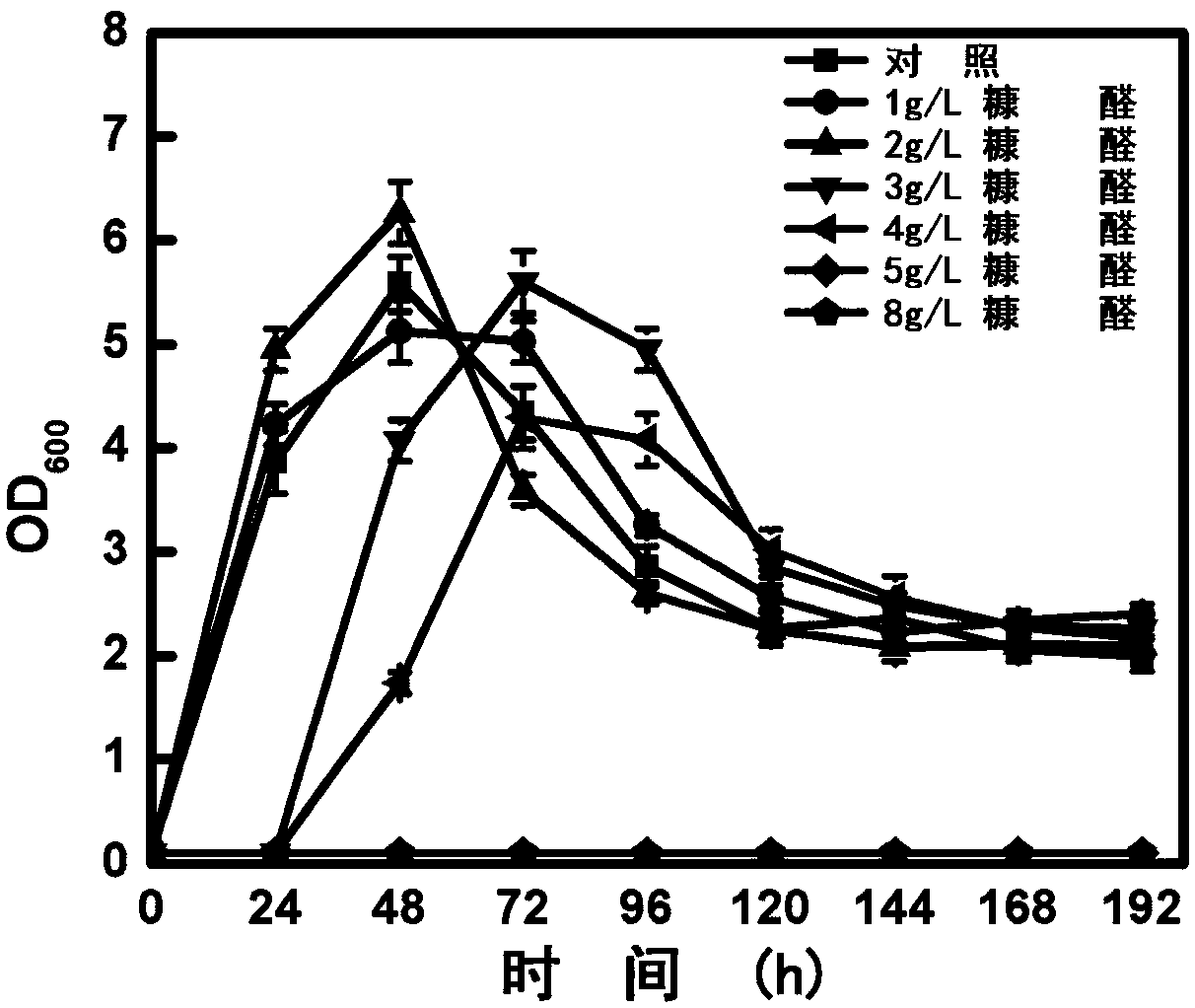

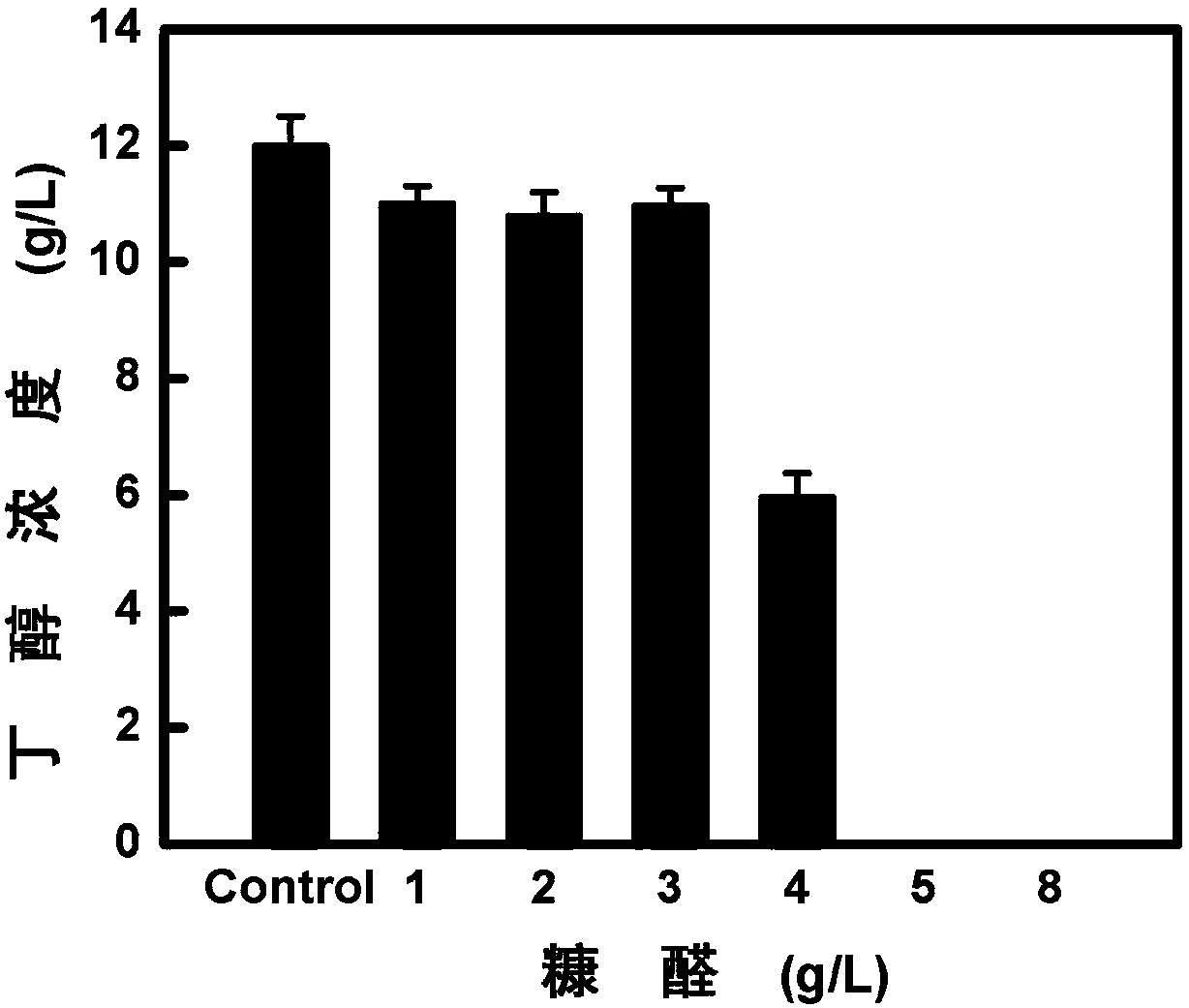

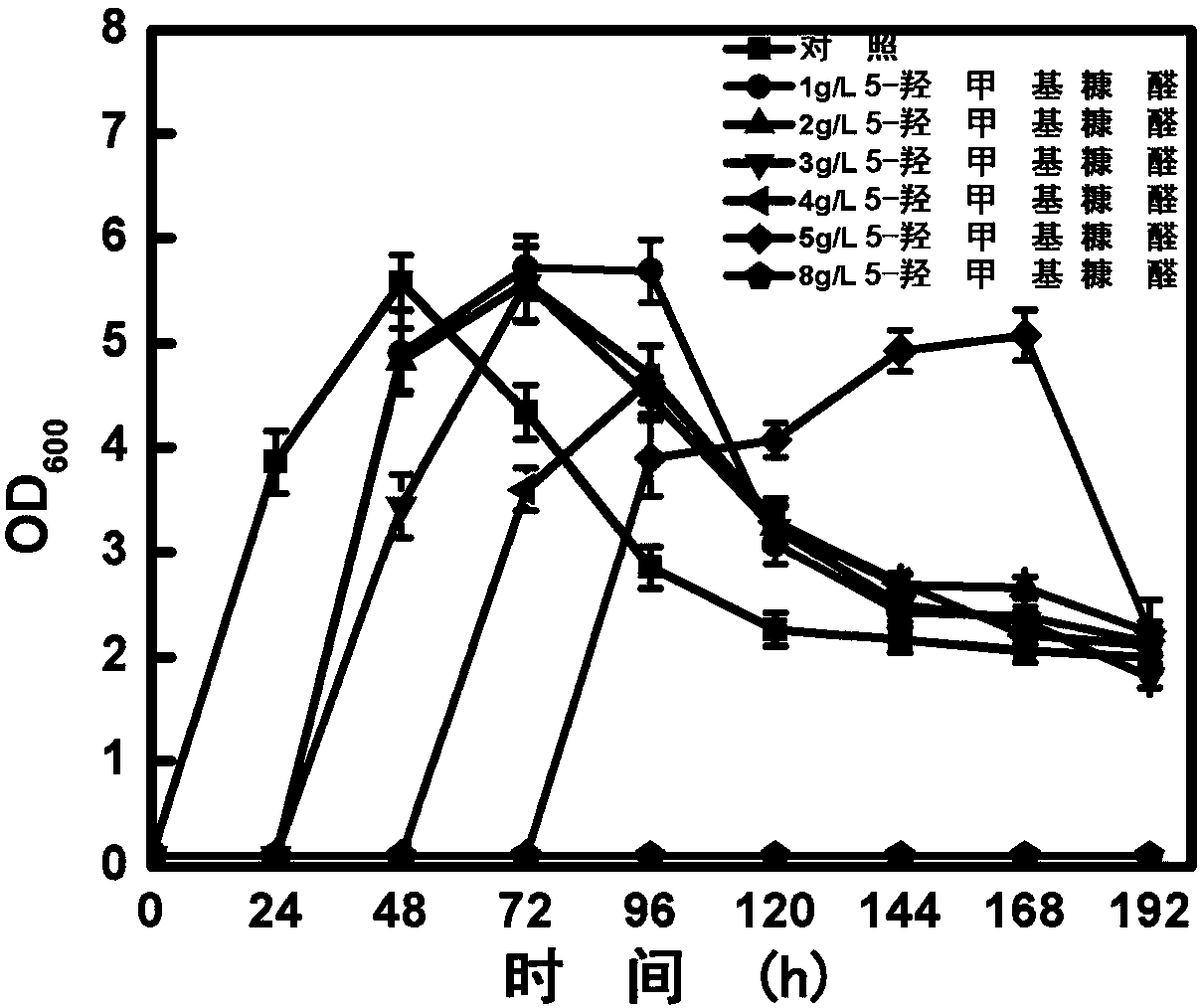

[0041] Example 3 Clostridium acetobutylicum C.acetobutylicum LJ4 growth OD and butanol production under different concentrations of furfural

[0042] Strain LJ4 can grow in the medium containing furfural, and at the furfural concentration of 1g / L, 2g / L, 3g / L, 4g / L, 5g / L, 8g / L, the growth status and fermentation of the bacteria LJ4 characteristics as an example.

[0043] Pick a single colony of strain LJ4 from the plate and inoculate it into 5mL liquid medium, at 37°C, 120r min -1 Cultivate for 48 hours, then inoculate into the fermentation medium with an inoculum size of 5% (v / v), 37°C, 120r·min -1 Shake the culture, adjust the pH to 5.5 every 24 hours, after 192 hours of fermentation, see the strain growth OD and butanol production figure 1 and figure 2 .

[0044] At 1g / L, 2g / L, 3g / L, 4g / L furfural concentrations, although the lag period of the bacterial strain LJ4 was extended, the growth condition was good, and the control butanol output without inhibitors was 12g / L. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com