High-strength door sheet material and preparation method thereof

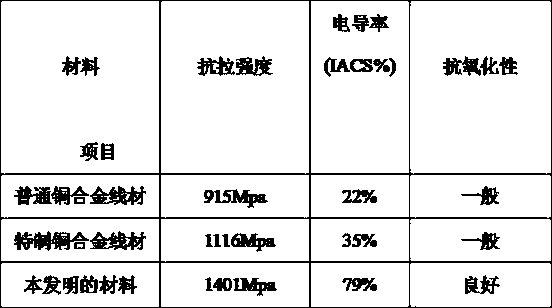

A high-strength, door panel technology, applied in the field of high-strength door panel materials and their preparation, can solve the problems of poor anti-oxidation effect and low tensile strength, achieve good anti-oxidation effect, eliminate surface static electricity, and improve tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A high-strength door panel material and a preparation method thereof, which are made of the following materials in parts by weight: 110 parts of copper, 5 parts of cobalt, 6 parts of chromium, 2 parts of zirconium, 7 parts of lanthanum, 0.2 parts of gold, and 15 parts of magnesium , 4 parts of molybdenum, 2 parts of barium diazenedicarboxylate, 6 parts of lithium aluminum hydride and 1 part of potassium borohydride.

[0021] A high-strength door panel material and a preparation method thereof, the preparation method comprising the following steps:

[0022] 1) 110 parts of copper, 5 parts of cobalt, 6 parts of chromium, 2 parts of zirconium, 7 parts of lanthanum, 0.2 parts of gold, 15 parts of magnesium, 4 parts of molybdenum, 2 parts of barium diazene dicarboxylate, 6 parts of lithium aluminum hydride 1 part and 1 part of potassium borohydride are put into a metal pulverizer, pulverized to obtain 80 mesh powder, and set aside;

[0023] 2) Put the raw materials obtained...

Embodiment 2

[0029] A high-strength door panel material and a preparation method thereof, which are made of the following materials in parts by weight: 115 parts of copper, 7.5 parts of cobalt, 7 parts of chromium, 3.5 parts of zirconium, 9 parts of lanthanum, 0.3 parts of gold, and 18.5 parts of magnesium , 5.5 parts of molybdenum, 5.5 parts of barium diazenedicarboxylate, 7.5 parts of lithium aluminum hydride and 1.5 parts of potassium borohydride.

[0030] A high-strength door panel material and a preparation method thereof, the preparation method comprising the following steps:

[0031] 1) 115 parts of copper, 7.5 parts of cobalt, 7 parts of chromium, 3.5 parts of zirconium, 9 parts of lanthanum, 0.3 parts of gold, 18.5 parts of magnesium, 5.5 parts of molybdenum, 5.5 parts of barium diazene dicarboxylate, 7.5 parts of lithium aluminum hydride 1.5 parts and 1.5 parts of potassium borohydride are put into a metal pulverizer, and pulverized to obtain 80 mesh powders, for subsequent use; ...

Embodiment 3

[0038] A high-strength door panel material and a preparation method thereof, which are made of the following materials in parts by weight: 120 parts of copper, 10 parts of cobalt, 8 parts of chromium, 5 parts of zirconium, 11 parts of lanthanum, 0.4 parts of gold, and 22 parts of magnesium , 7 parts of molybdenum, 9 parts of barium diazenedicarboxylate, 9 parts of lithium aluminum hydride and 2 parts of potassium borohydride.

[0039] A high-strength door panel material and a preparation method thereof, the preparation method comprising the following steps:

[0040] 1) 120 parts of copper, 10 parts of cobalt, 8 parts of chromium, 5 parts of zirconium, 11 parts of lanthanum, 0.4 parts of gold, 22 parts of magnesium, 7 parts of molybdenum, 9 parts of barium diazene dicarboxylate, 9 parts of lithium aluminum hydride 2 parts and 2 parts of potassium borohydride are put into the metal pulverizer, pulverized to obtain 80 mesh powders, for subsequent use;

[0041] 2) Put the raw mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com