Preparation method of infrared camouflage textile

An infrared camouflage and textile technology, which is applied in the field of preparation of infrared camouflage textiles, can solve problems such as difficulty, and achieve the effects of simple operation and good bonding fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

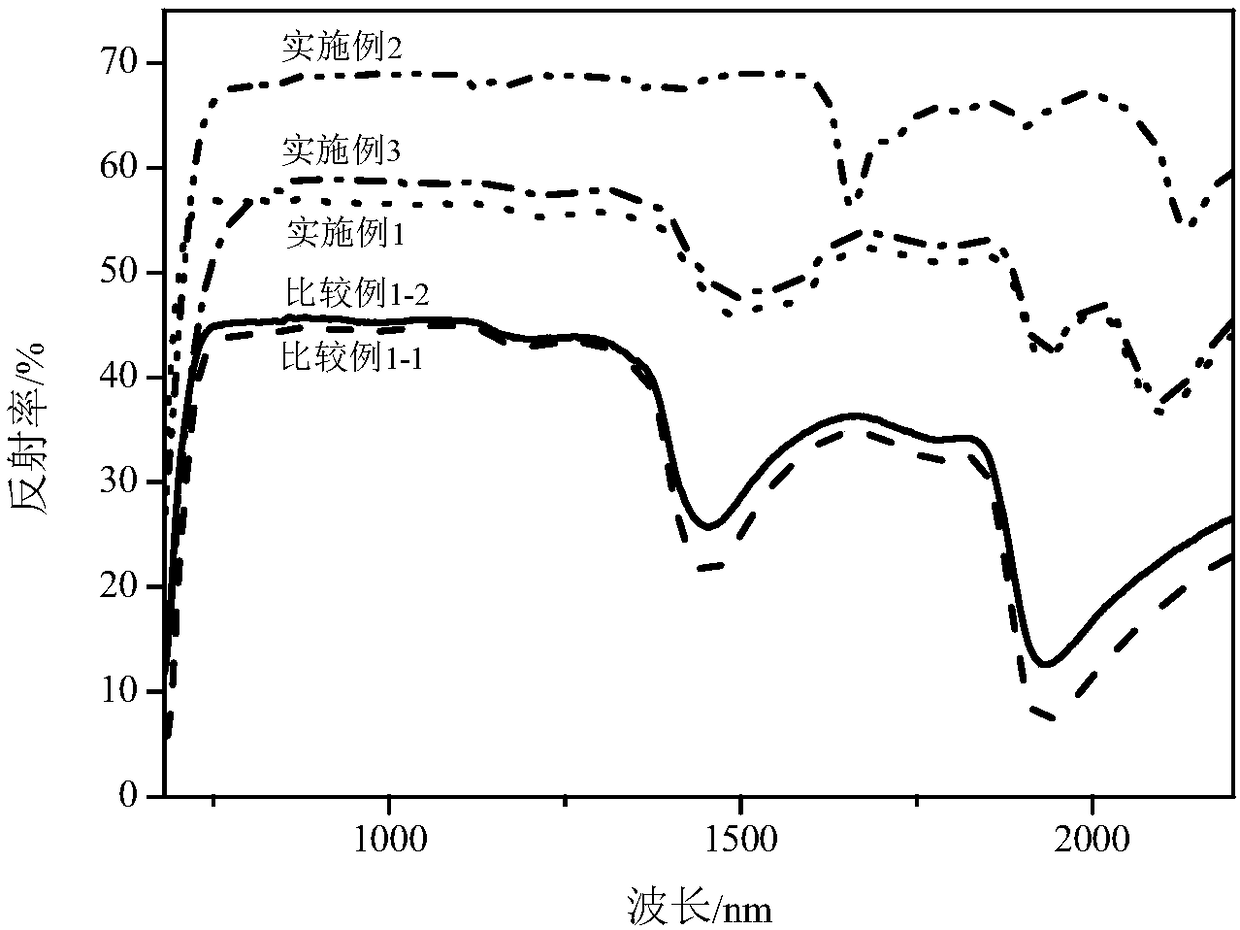

Examples

Embodiment 1

[0024] (1) Place the aluminum-doped zinc oxide powder in the chamber of the low-temperature plasma processing instrument, turn on the vacuum pump, and when the vacuum degree in the reaction chamber is 3Pa, feed ammonia gas, adjust the gas flow rate until the vacuum degree in the reaction chamber is 20Pa; stable After 3 minutes, glow discharge, discharge power 150W, discharge time 8 minutes, after the discharge, continue to pass ammonia gas and keep it for 10 minutes;

[0025] (2) Take 100mL of 0.1mol / L phosphate buffer solution with pH 7.0, put it in a 250mL three-neck flask, add 50mg of aluminum-doped zinc oxide treated in step (1), and stir thoroughly; accurately weigh 50mg of 1-ethyl-3 -(3-Dimethylaminopropyl)carbodiimide hydrochloride and 100mg N-hydroxysuccinimide were respectively dissolved in 20mL of pH 7.0 phosphate buffer solution, and then the two were added to a three-necked flask and stirred vigorously 30min to fully activate aluminum-doped zinc oxide; accurately w...

Embodiment 2

[0042] (1) Place the aluminum-doped zinc oxide powder in the chamber of the low-temperature plasma processing instrument, turn on the vacuum pump, and when the vacuum degree in the reaction chamber is 3Pa, feed ammonia gas, adjust the gas flow rate until the vacuum degree in the reaction chamber is 50Pa; stable After 5 minutes, glow discharge, discharge power 200W, discharge time 5 minutes, after the discharge, continue to pass ammonia gas and keep it for 10 minutes;

[0043] (2) Take 100mL of 0.1mol / L phosphate buffer solution with pH 7.0, put it in a 250mL three-neck flask, add 50mg of aluminum-doped zinc oxide treated in step (1), and stir thoroughly; accurately weigh 100mg of 1-ethyl-3 -(3-Dimethylaminopropyl)carbodiimide hydrochloride and 150mg N-hydroxysuccinimide were dissolved in 20mL of pH 7.0 phosphate buffer solution respectively, and then the two were added to a three-necked flask and stirred vigorously 30min to fully activate aluminum-doped zinc oxide; accurately we...

Embodiment 3

[0048] (1) Place the aluminum-doped zinc oxide powder in the chamber of the low-temperature plasma processing apparatus, turn on the vacuum pump, and when the vacuum in the reaction chamber is 3Pa, feed ammonia gas, and adjust the gas flow until the vacuum in the reaction chamber is 30Pa; stable After 4 minutes, glow discharge, discharge power 180W, discharge time 6 minutes, after the discharge, continue to pass ammonia gas and keep it for 10 minutes;

[0049] (2) Take 100mL 0.1mol / L pH 7.0 phosphate buffer solution, put it in a 250mL three-neck flask, add 50mg of aluminum-doped zinc oxide treated in step (1), and stir thoroughly; accurately weigh 60mg of 1-ethyl-3 -(3-Dimethylaminopropyl)carbodiimide hydrochloride and 120mg N-hydroxysuccinimide were dissolved in 20mL of pH 7.0 phosphate buffer solution respectively, and then the two were added into a three-necked flask and stirred vigorously 30min to fully activate aluminum-doped zinc oxide; accurately weigh 120mg of octacarb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com