A kind of preparation method of blue titanium dioxide

A titanium dioxide and blue technology, applied in the field of inorganic nano-photocatalytic materials, can solve problems such as poor stability, high cost, and complicated operation, and achieve the effects of low cost, simple preparation method, and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix 5 mL of tetra-n-butyl titanate with 6.1 mL of trifluoroacetic acid in a molar ratio of 1:3 to obtain a mixture;

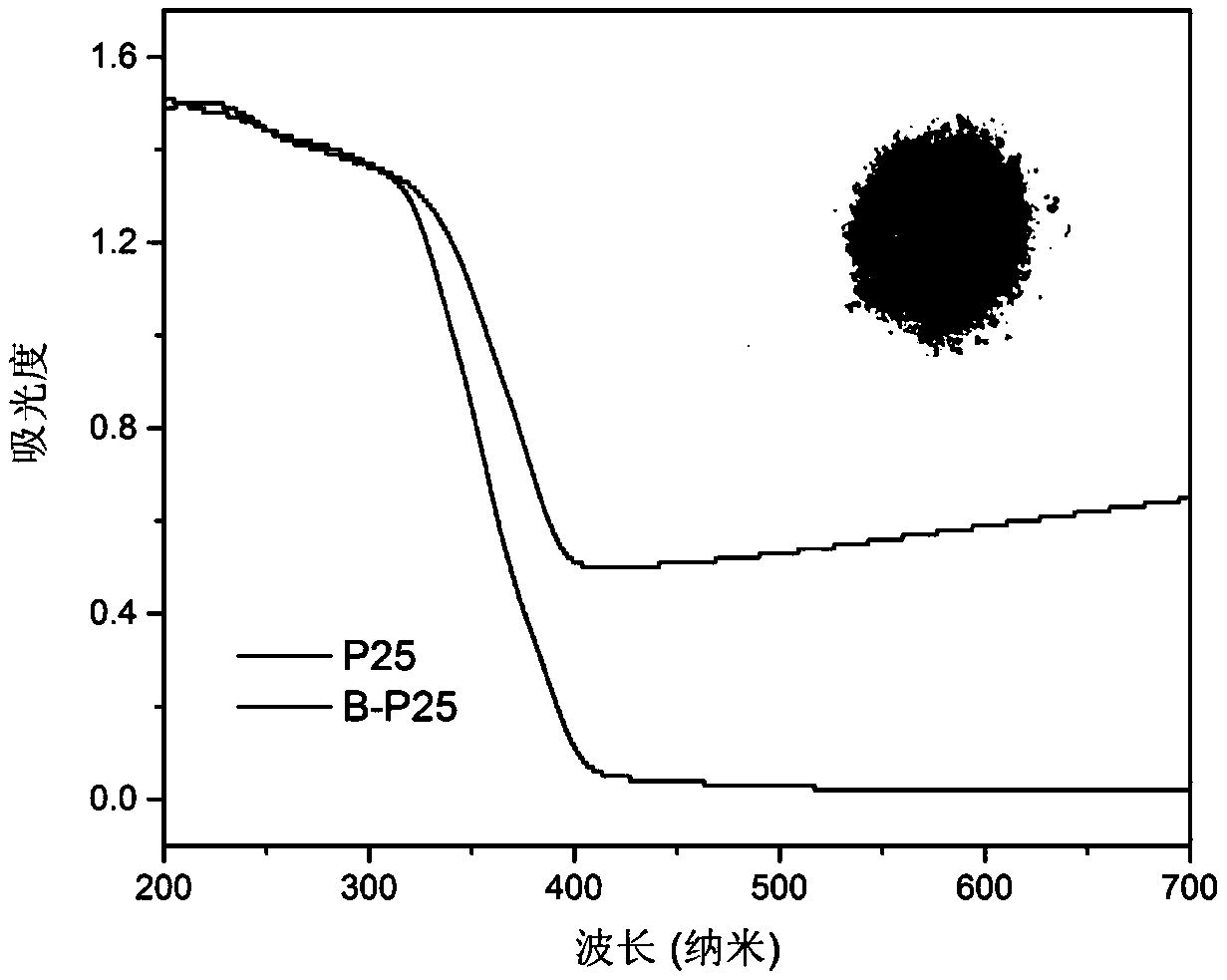

[0028] (2) Add the above mixture to 2.48g LiCl and 3.1g KCl molten salt and grind it evenly, then place it in a muffle furnace and calcinate at a high temperature of 400°C for 6h (see figure 1 );

[0029] (3) After cooling, wash with water to remove the molten salt to obtain blue titanium dioxide with a grain size of about 25nm (see figure 2 ). Its photocatalytic degradation efficiency of rhodamine B is higher than commercial titanium dioxide P25 (see Figure 5 ).

Embodiment 2

[0031] (1) Mix 5 mL of tetra-n-butyl titanate with 12.2 mL of trifluoroacetic acid in a molar ratio of 1:6 to obtain a mixture;

[0032] (2) Add the above mixture to 2.48g LiCl and 3.1g KCl molten salt and grind evenly, then place it in a muffle furnace and calcinate at a high temperature of 500°C for 6h;

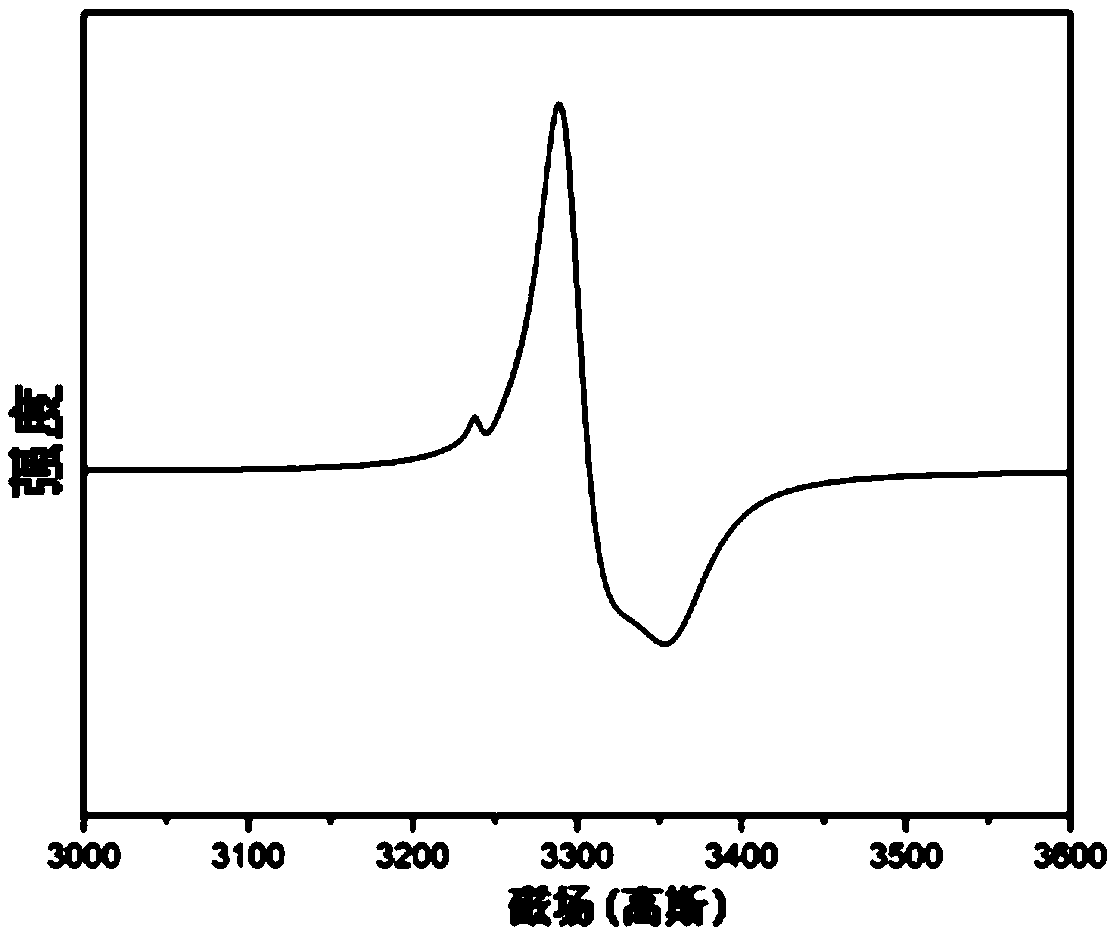

[0033] (3) After cooling, wash with water to remove molten salt to obtain blue titanium dioxide, and its electron paramagnetic resonance spectrum shows that blue titanium dioxide contains a large amount of Ti 3+ (See image 3 ), illustrating that the preparation method of the present invention can obtain highly stable blue titanium dioxide. Its photocatalytic degradation efficiency of rhodamine B is higher than commercial titanium dioxide P25 (see Figure 5 ).

Embodiment 3

[0035] (1) Mix 5 mL of tetra-n-butyl titanate with 12.2 mL of trifluoroacetic acid in a molar ratio of 1:6 to obtain a mixture;

[0036] (2) Add the above mixture to 3.57g LiNO 3 and 5.76g KNO 3 Grind it evenly in molten salt, then place it in a muffle furnace and calcinate at 600°C for 3 hours;

[0037] (3) After cooling, wash with water to remove the molten salt to obtain blue titanium dioxide, and its X-ray photoelectron energy diagram shows that blue titanium dioxide contains Ti 3+ (See Figure 4 ), illustrating that the preparation method of the present invention can obtain blue titanium dioxide with good stability. The efficiency of its photocatalytic degradation of rhodamine B is better than that of commercial titanium dioxide P25 (see Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com