Domestic wastewater sedimentation device

A technology of sedimentation device and domestic sewage, applied in sedimentation treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of incapable of solid particle treatment, complicated salvage and transportation mechanism, affecting salvage efficiency, etc. Promote the efficiency of precipitation treatment, ingenious structural design, and improve the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

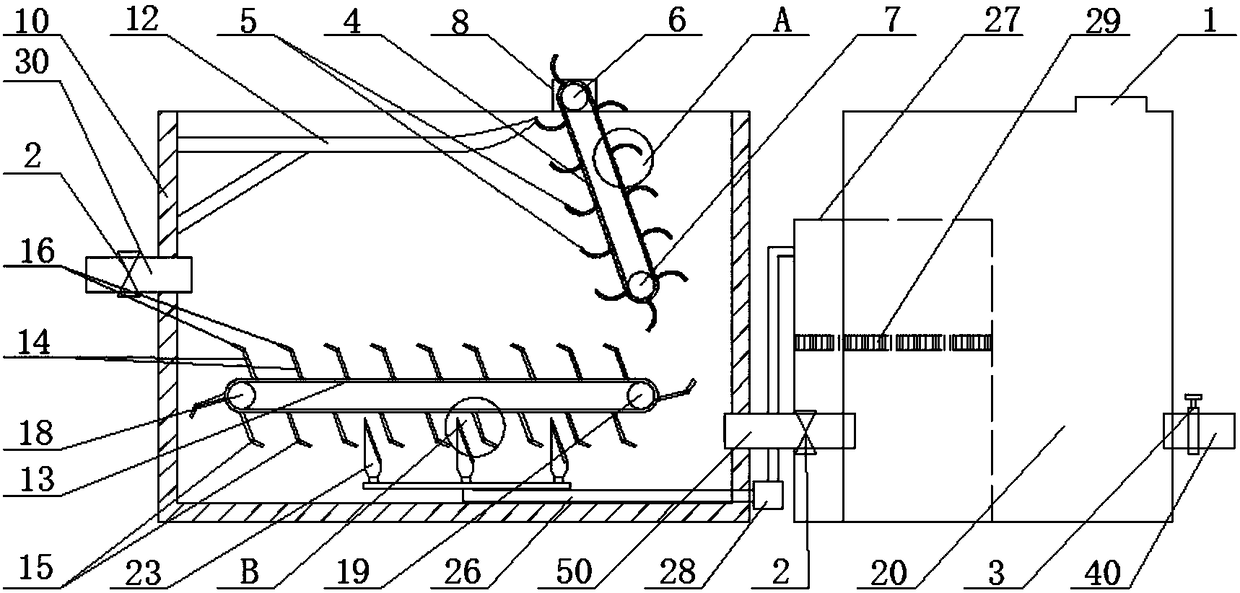

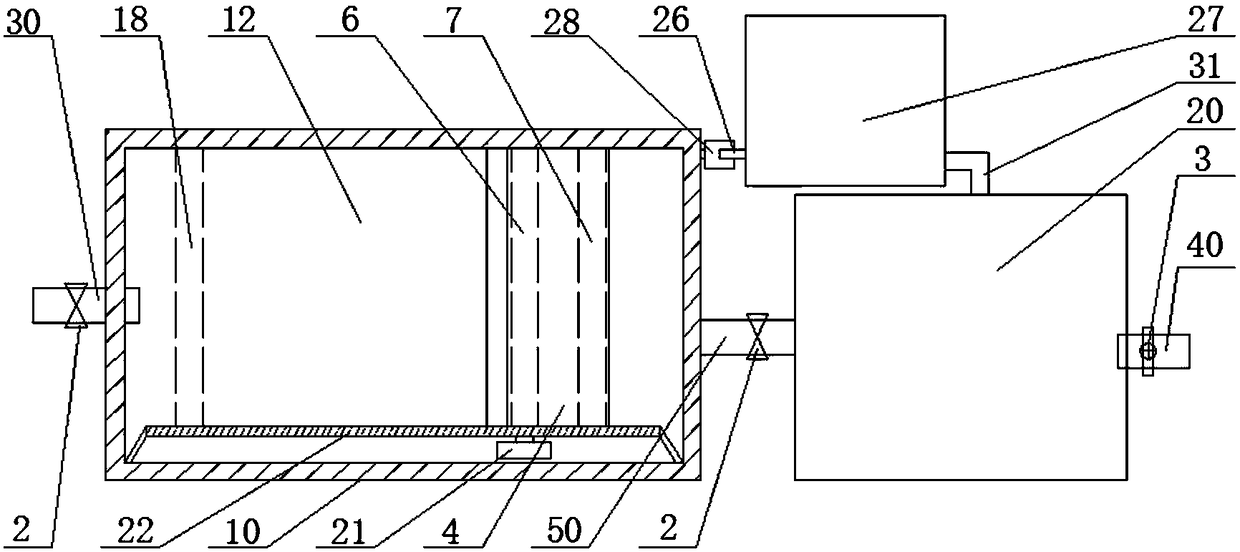

[0033] Such as figure 1 A kind of domestic sewage sedimentation device shown comprises a sedimentation box body, a water inlet pipe 30 and a water outlet pipe 40, and the sedimentation box body includes a primary sedimentation tank 10 and a secondary sedimentation tank 20 connected by an intermediate connecting pipe 50. The upper end of the primary sedimentation tank 10 is open, the upper end of the secondary sedimentation tank 20 is provided with a feeding port 1, the water inlet pipe 30 is arranged on the primary sedimentation tank 10 and is opposite to the intermediate connecting pipe 50, and the water outlet pipe 40 Set on the secondary settling tank 20 and opposite to the intermediate connecting pipe 50, the part below the outlet pipe 40 in the secondary settling tank 20 is a sludge sedimentation area, and the inlet pipe 30 and the intermediate connecting pipe 50 are provided with There is a solenoid valve 2, an on-off valve 3 is provided on the outlet pipe 40, a surface ...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is:

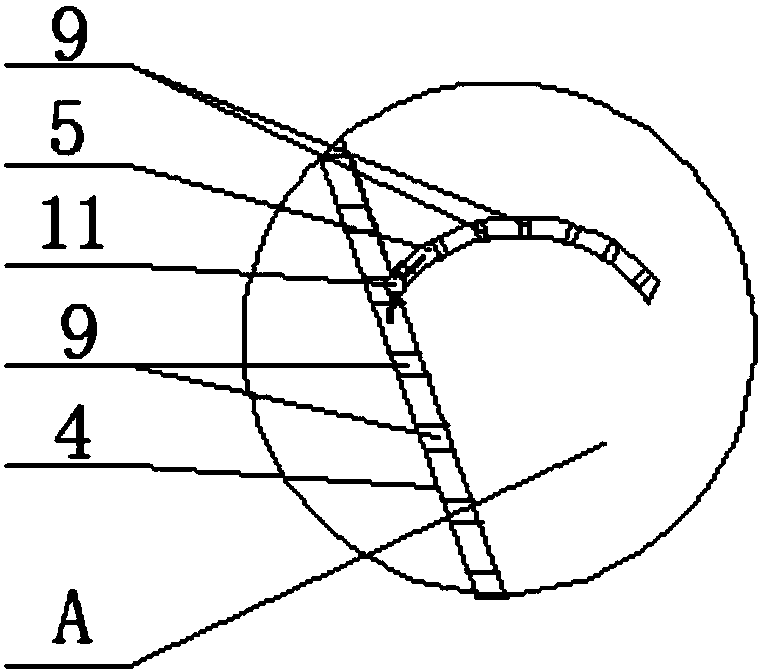

[0040] Such as Figure 7 As shown, the transmission assembly 21 includes a rotating shaft 1 214 and a rotating shaft 2 215 respectively connected to the center of the driven pulley 7 and the driven pulley 19, and the first rotating shaft 214 and the second rotating shaft 215 are respectively provided with a gear 1 216 and Gear two 217, said gear one 216 and gear two 217 are positioned at the side opposite to conveyor belt one 4 of dividing plate 22, as Figure 8 As shown, the corresponding positions on the partition 22 are respectively provided with perforations 222 for the first rotating shaft 214 and the second rotating shaft 215 to pass through; between the first gear 216 and the second gear 217, there is a simultaneous meshing gear one 216 and gear two The transmission gear 218 of 217.

[0041] Others are the same as embodiment 1.

[0042] During application, rotating shaft 1 214 rotates with the rotat...

Embodiment 3

[0044] The difference between this embodiment and embodiment 2 is:

[0045] Such as Figure 9 As shown, the first gear 216 and the second gear 217 directly mesh with each other.

[0046] Others are the same as embodiment 2.

[0047] As mentioned above, after gear one rotates with rotating shaft one 214, driving gear two rotates, and gear two drives rotating shaft two 215 to rotate, and rotating shaft two 215 drives driven wheel three 19 to rotate, thereby can drive conveyor belt two 13 to run smoothly; At this moment, driven wheel three The rotation direction of 19 is opposite to the rotation direction of the driven pulley 7, and the adsorption plate 14 moves against the direction of water flow, which can better realize the adsorption of solid particles in the water body.

[0048] The specific application process of the above domestic sewage sedimentation device is as follows:

[0049] (1) Water intake: the domestic sewage to be treated is passed into the primary sedimentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com