Odorless regenerable rubber and automobile foot mat prepared from regenerable rubber

A technology for reclaimed rubber and reclaimed rubber, applied in the field of automobile mats, can solve the problems of limited application of reclaimed rubber, poor aging resistance, low hydrocarbon content, etc., and achieve the effects of inhibiting rise, improving aging resistance, and inhibiting fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

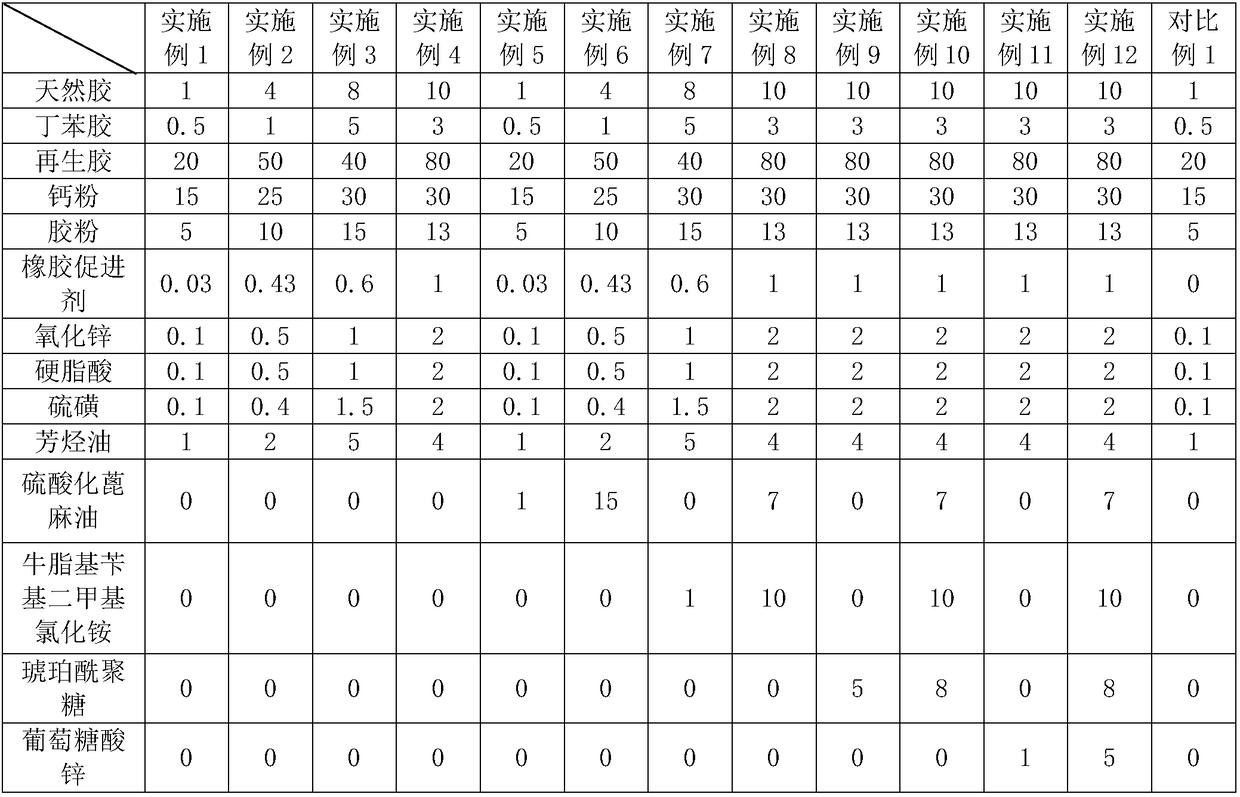

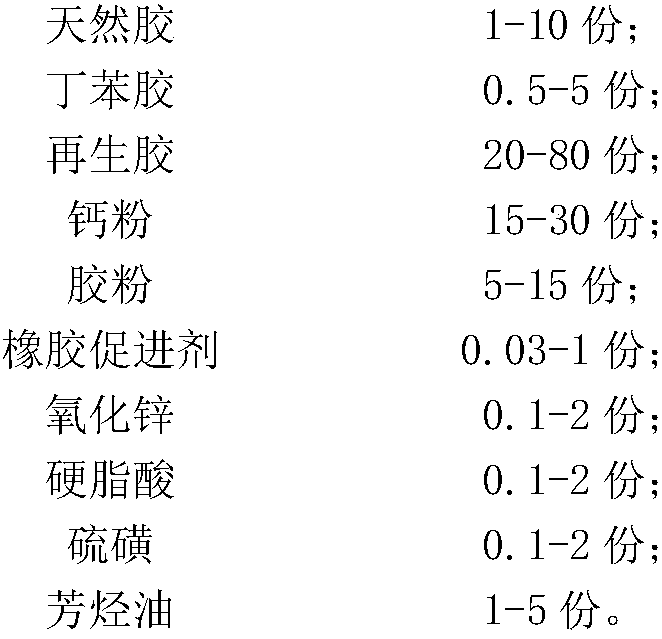

[0024] Embodiment 1: A kind of odorless regenerated rubber, each component and content in the raw material are as shown in Table 1, and the unit of each component in Table 1 is kg. Among them, the rubber accelerator is rubber accelerator DM, and the reclaimed rubber is butyl regenerated rubber.

[0025] The preparation process of odorless recycled rubber: step 1, batching, using an open mixer, the temperature of the mixing drum is always controlled at 50-60 °C, adjusting the roller distance of the mixer to 8mm, adding natural rubber, styrene-butadiene rubber, and recycled rubber , Calcium powder, rubber powder, zinc oxide, stearic acid, and sulfur were kneaded for 5 minutes, then added aromatic oil and kneaded for 8 minutes, and finally rubber accelerator, kneaded for 1 minute.

[0026] Secondly, adjust the roller distance of the mixer to 1.5mm, and thin pass 5 times;

[0027] Finally, adjust the roller distance of the mixer to 8m, beat evenly, and then remove the sheet, and ...

Embodiment 2

[0030] Embodiment 2: a kind of odorless regenerated rubber, the difference with embodiment 1 is that each component and content are as shown in table 1 in the raw material, rubber accelerator comprises 0.2kg rubber accelerator DM, 0.2kg rubber accelerator M , 0.03kg rubber accelerator TMTD, the reclaimed rubber is nitrile butadiene regenerated rubber.

Embodiment 3

[0031] Embodiment 3: a kind of tasteless reclaimed rubber, the difference with embodiment 1 is that each component and content are as shown in table 1 in the raw material, rubber accelerator is rubber accelerator M, and reclaimed rubber is ethylene propylene regenerated rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com