SERS substrate preparation and detection integrated method based on micro flow mixer

A mixer and substrate technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problem of low utilization rate of "hot spots", and achieve the effect of maintaining natural activity, enhancing effect, and reducing oxidation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

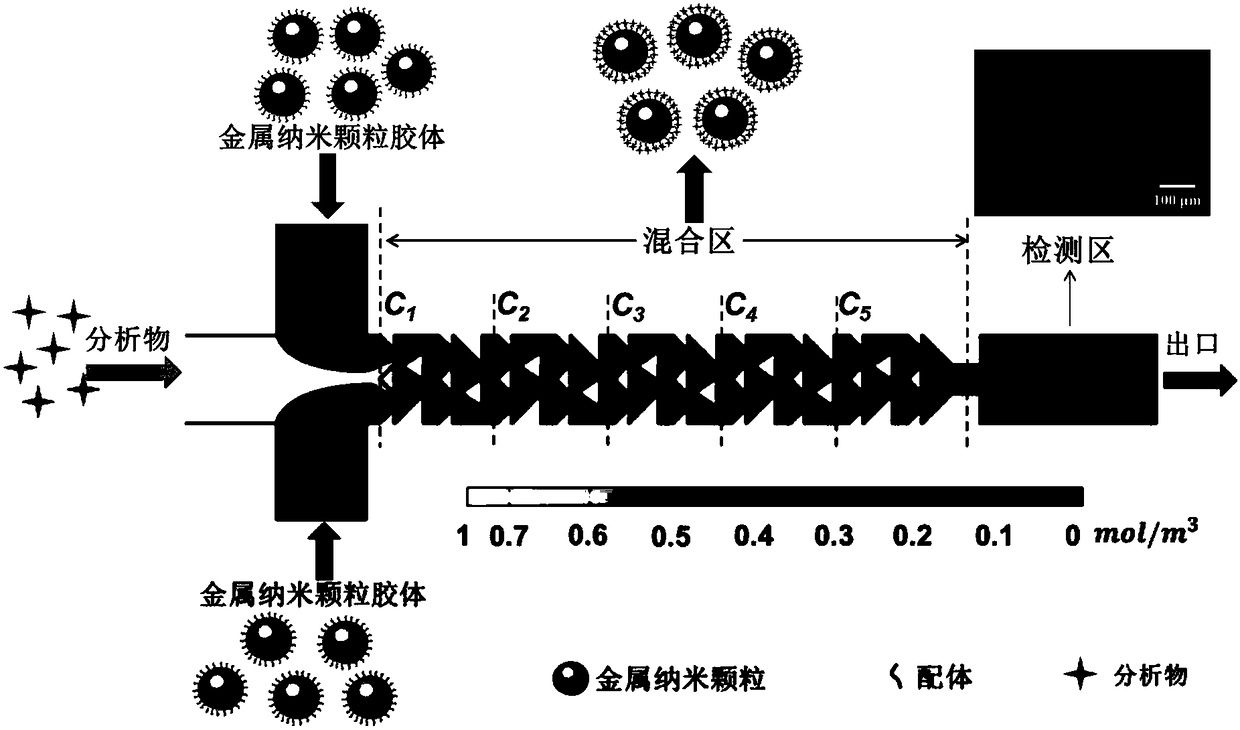

[0030] Example 1: Uniformity Characterization of SERS Substrate Based on Microfluidic Mixer

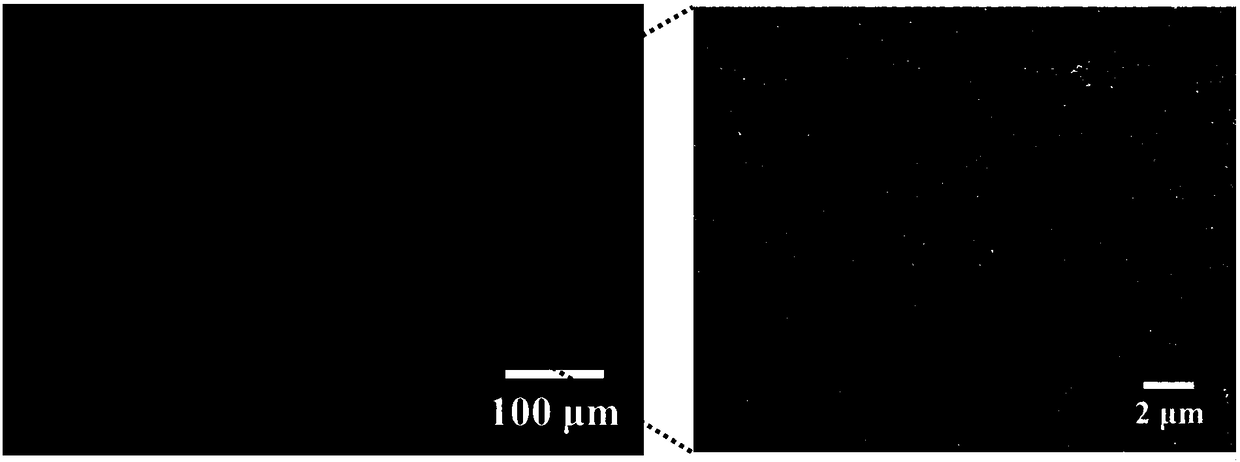

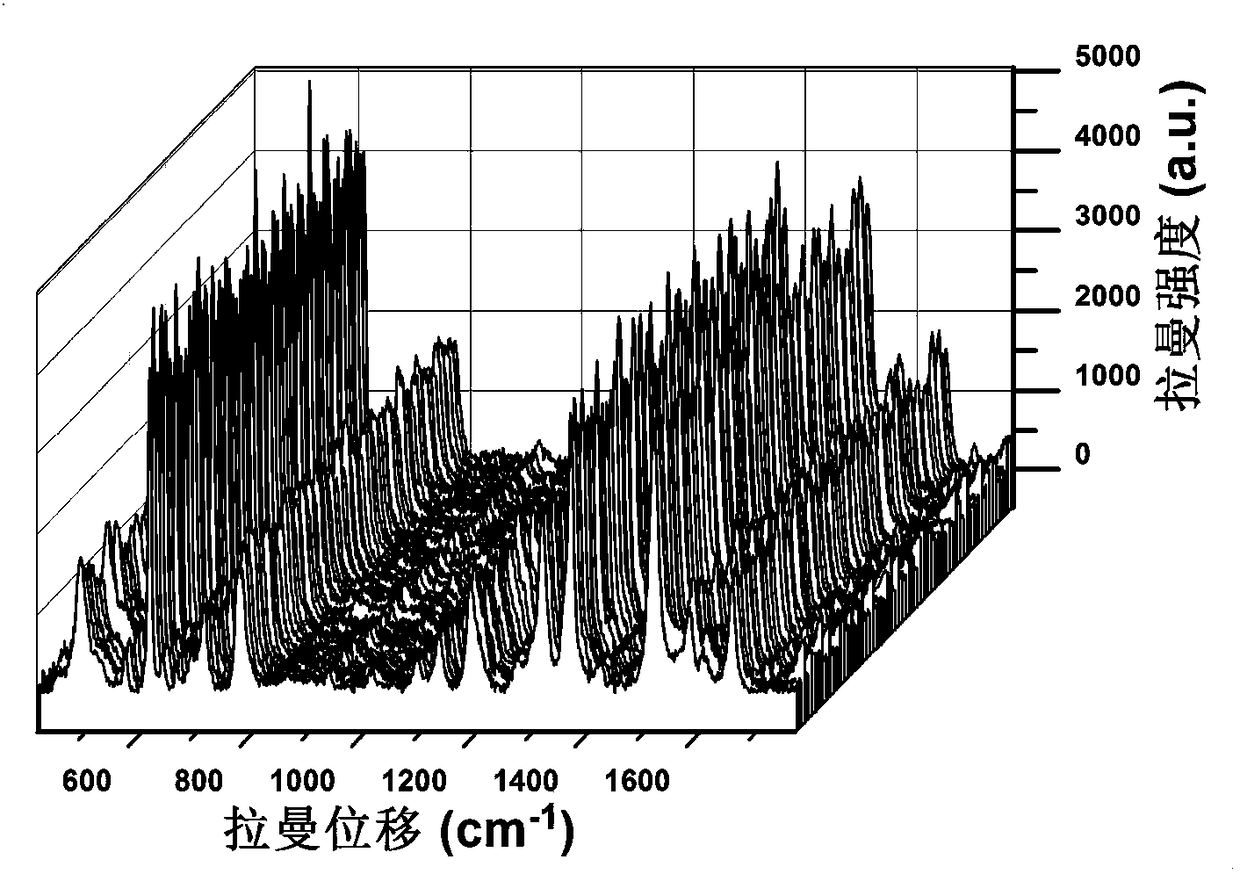

[0031] The colloidal solution of silver nanoparticles was introduced simultaneously from the two side channels of the freshly prepared C-SAR microfluidic mixer at a flow rate of 200 μl / min; the R6G solution of 2.2 nM was introduced from the main channel at a flow rate of 40 μl / min; The mixing zone fully and quickly mixes the analyte and metal nanoparticles; R6G can be evenly adsorbed on the surface of the nanoparticles. The silver nanoparticles adsorbed with R6G were deposited on the detection area of the microfluidic chip. After 10 minutes, deionized water was passed through the three inlet channels to remove excess unadsorbed particles, and a uniform single-layer silver nanoparticle film was obtained. Such as figure 2 shown. 60 points are randomly detected in the detection area, and the obtained SERS spectrum of R6G is as follows image 3 As shown, the deviation of the signal ...

Embodiment 2

[0032] Example 2: Characterization of long-term stability of SERS substrates based on microfluidic mixers

[0033] The colloidal solution of silver nanoparticles was introduced simultaneously from the two side channels of the freshly prepared C-SAR microfluidic mixer at a flow rate of 200 μl / min; the R6G solution of 2.2 nM was introduced from the main channel at a flow rate of 40 μl / min; The mixing zone fully and quickly mixes the analyte and metal nanoparticles; R6G can be evenly adsorbed on the surface of the nanoparticles. The silver nanoparticles adsorbed with R6G were deposited on the detection area of the microfluidic chip. After 10 minutes, the three inlet channels were fed with deionized water to remove excess unadsorbed particles, and a uniform single-layer silver nanoparticle film was obtained. For the SERS spectrum of R6G, place the chip in the air for 10 weeks, and test the SERS spectrum of R6G in the detection area once a week, such as Figure 4 As shown, there...

Embodiment 3

[0034] Example 3: Characterization of the detection capability of the SERS substrate based on the microfluidic mixer

[0035] The colloidal solution of silver nanoparticles was simultaneously passed through two side channels of the freshly prepared C-SAR microfluidic mixer at a flow rate of 200 μl / min; 10 -7 ,5×10 -8 ,10 -8 ,5×10 -9 ,10 -9 The R6G solution of M was passed through the main channel at a flow rate of 40 μl / min; the analyte and metal nanoparticles were mixed fully and rapidly in the mixing zone; R6G could be evenly adsorbed on the surface of the nanoparticles. The concentration of R6G in the detection area is 9×10 -9 ,4.5×10 -9 ,9×10 -10 ,4.5×10 -10 ,2×10 -10 and 9×10 -11 M, silver nanoparticles adsorbed with R6G were deposited on the detection area of the microfluidic chip, and after 10 minutes, the three inlet channels were fed with deionized water to remove excess unadsorbed particles, and a series of uniform single-layer silver nanoparticle films we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com