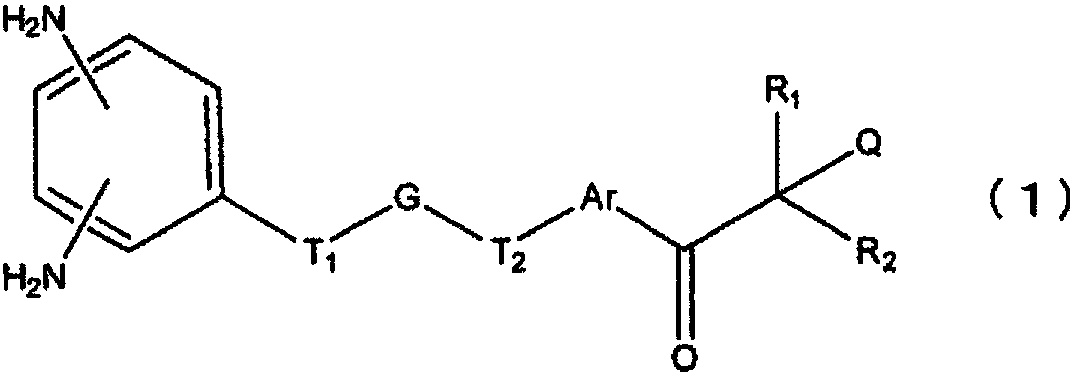

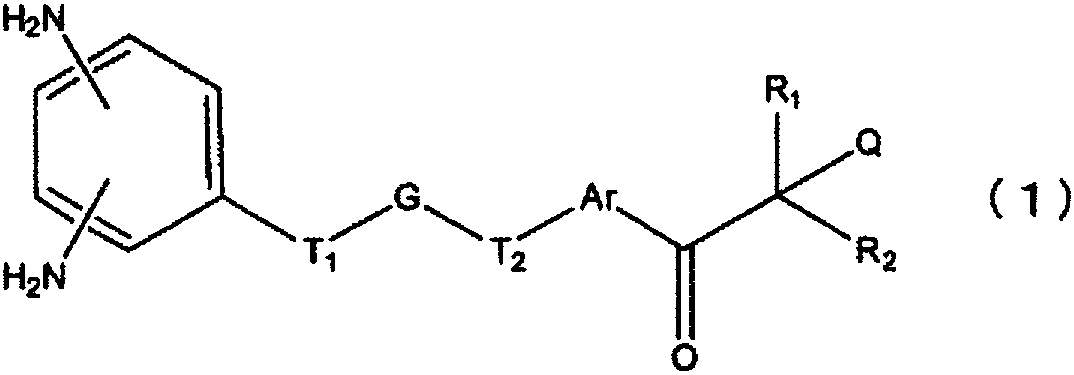

Novel diamine compound having radical generation ability and base generation ability, and novel imide polymer using said novel diamine compound as starting material

An amine compound and imide-based technology, applied in organic chemistry, instruments, optics, etc., can solve problems such as component decomposition, reliability reduction, and liquid crystal display element reliability reduction, and achieve fast response and high efficiency tilt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

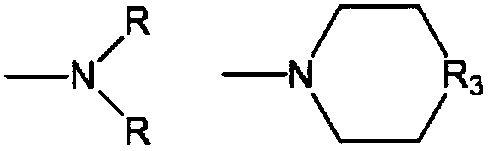

Method used

Image

Examples

Embodiment 1

[0197] BODA (1.30 g, 5.2 mmol), 3AMPDA (0.63 g, 2.6 mmol), DA-1 (2.20 g, 5.2 mmol), and DA-2 (1.98 g, 5.2 mmol) were dissolved in NMP (22.8 g), After making it react at 60 degreeC for 5 hours, CBDA (1.50g, 7.7mmol) and NMP (7.6g) were added, it was made to react at 40 degreeC for 10 hours, and the polyamic-acid solution was obtained.

[0198] After adding NMP to this polyamic-acid solution (34g) and diluting to 6.5 mass %, acetic anhydride (5.9g) and pyridine (1.8g) were added as an imidization catalyst, and it was made to react at 70 degreeC for 3 hours. This reaction solution was poured into methanol (500 ml), and the obtained precipitate was filtered off. This deposit was wash|cleaned with methanol, it dried under reduced pressure at 100 degreeC, and the polyimide powder (A) was obtained. The imidization rate of this polyimide was 76%, the number average molecular weight was 13000, and the weight average molecular weight was 48000.

[0199] NMP (22.0g) was added to the ob...

Embodiment 2

[0219] Glycidyl methacrylate (GMA) (7.11 g, 50.0 mmol) and methyl methacrylate (MMA) (5.01 g, 50.0 mmol) were dissolved in NMP (116.4 g), and degassed with a diaphragm pump for 5 minutes, Then, azobisisobutyronitrile (AIBN) (0.82 g, 5.0 mmol) was added, and deaeration was performed again for 5 minutes. Then, it was made to react at 60 degreeC for 30 hours, and the 1:1 copolymer of GMA and MMA was obtained. Butyl cellosolve (BCS) (86.2g) was added to this polymer solution, and the polymethacrylate solution (C) of 6 mass % was obtained. The polymer had a number average molecular weight of 6800 and a weight average molecular weight of 10800.

[0220] DA-1 (42.3 mg, 0.1 mmol) was added and melt|dissolved to this solution (C) (10.0g), and the polymethacrylate solution (C1) was obtained.

[0221] "Confirmation of the ability of light to generate bases"

[0222] The polymethacrylate solution (C1) obtained above was spin-coated on the ITO surface of the ITO electrode substrate, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com