Production method of intestinal tract regulator

An intestinal regulator and production method technology, applied in the field of microorganisms, can solve problems such as dust air pollution, and achieve the effects of high safety, enhancing vitality and resistance to stress, and improving survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

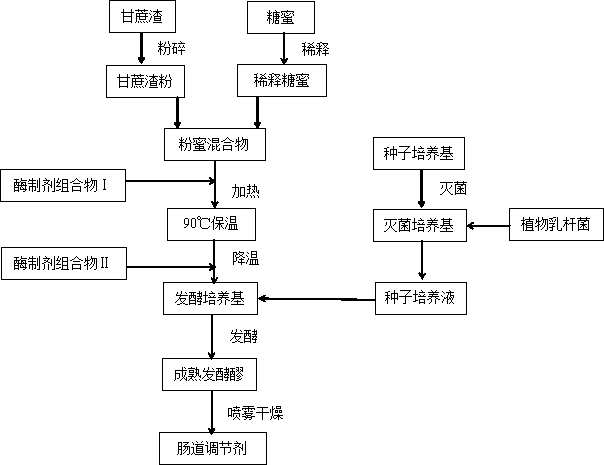

[0053] A method for producing an intestinal regulator, comprising the steps of:

[0054] (1) Crushing bagasse into bagasse powder passing through a 100-mesh sieve;

[0055] (2) Configure the seed medium, adjust the pH to 6.5, keep the medium at 121°C for 15 minutes, and sterilize it. The medium is composed of the following components in mass percentage: 92% water, 4% Molasses, 2.5% peptone, 1.5% yeast extract;

[0056] (3) Inoculate Lactobacillus plantarum into the medium sterilized in step (2), keep the temperature at 36.2°C, rotate at 80 rpm, and cultivate for 5.5 hours to obtain the seed culture solution;

[0057] (4) Dilute the molasses to a Brix of 20Bx, and mix evenly with the bagasse powder prepared in step (1) accounting for 22% of the total mass percentage of the diluted liquid to obtain a powder-honey mixture;

[0058] (5) Add 0.75% by mass of enzyme composition I to the powder-honey mixture prepared in step (4), slowly heat to 95°C while stirring at a rotating spe...

Embodiment 2

[0063] A method for producing an intestinal regulator, comprising the steps of:

[0064] (1) Crushing bagasse into bagasse powder passing through a 100-mesh sieve;

[0065] (2) Prepare the seed medium, adjust the pH to 7.0, keep the medium at 121°C for 15 minutes, and sterilize it. The medium is composed of the following components in mass percentage: 95% water, 2% Molasses, 2% peptone, 1% yeast extract;

[0066] (3) Inoculate Lactobacillus plantarum into the medium sterilized in step (2), keep the temperature at 38°C, rotate at 100rpm, and cultivate for 6 hours to obtain the seed culture solution;

[0067] (4) Dilute the molasses to a Brix of 25Bx, and mix evenly with the bagasse powder prepared in step (1) accounting for 35% of the total mass percentage of the diluted liquid to obtain a powder-honey mixture;

[0068] (5) Add 0.8% by mass of enzyme preparation composition I to the powder-honey mixture prepared in step (4), slowly heat to 100°C while stirring at a rotating s...

Embodiment 3

[0073] A method for producing an intestinal regulator, comprising the steps of:

[0074] (1) Crushing bagasse into bagasse powder passing through a 100-mesh sieve;

[0075] (2) Configure the seed medium, adjust the pH to 6.2, keep the medium at 121°C for 15 minutes, and sterilize it. The medium is composed of the following components in mass percentage: 90% water, 5% Molasses, 4% peptone, 1% yeast extract;

[0076] (3) Inoculate Lactobacillus plantarum into the medium sterilized in step (2), keep the temperature at 35°C, rotate at 60rpm, and cultivate for 5 hours to obtain the seed culture solution;

[0077] (4) Dilute the molasses to a Brix of 15Bx, and mix evenly with the bagasse powder prepared in step (1) which accounts for 15% of the total mass percentage of the diluted liquid, to obtain a powder-honey mixture;

[0078] (5) Add 1% by mass of enzyme preparation composition I to the powder-honey mixture prepared in step (4), slowly heat to 90°C while stirring at a rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com