Preparation method of ternary semiconductor catalyst

A catalyst and semiconductor technology, applied in the field of preparation of ternary semiconductor catalysts, can solve the problem of low separation efficiency of photogenerated carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

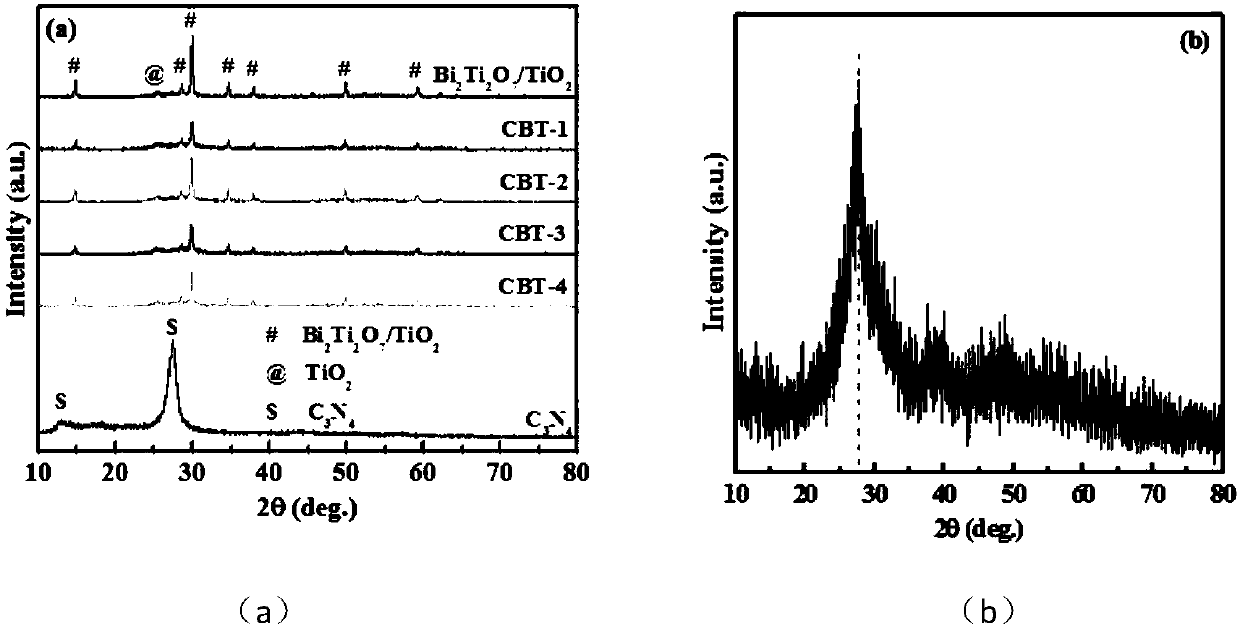

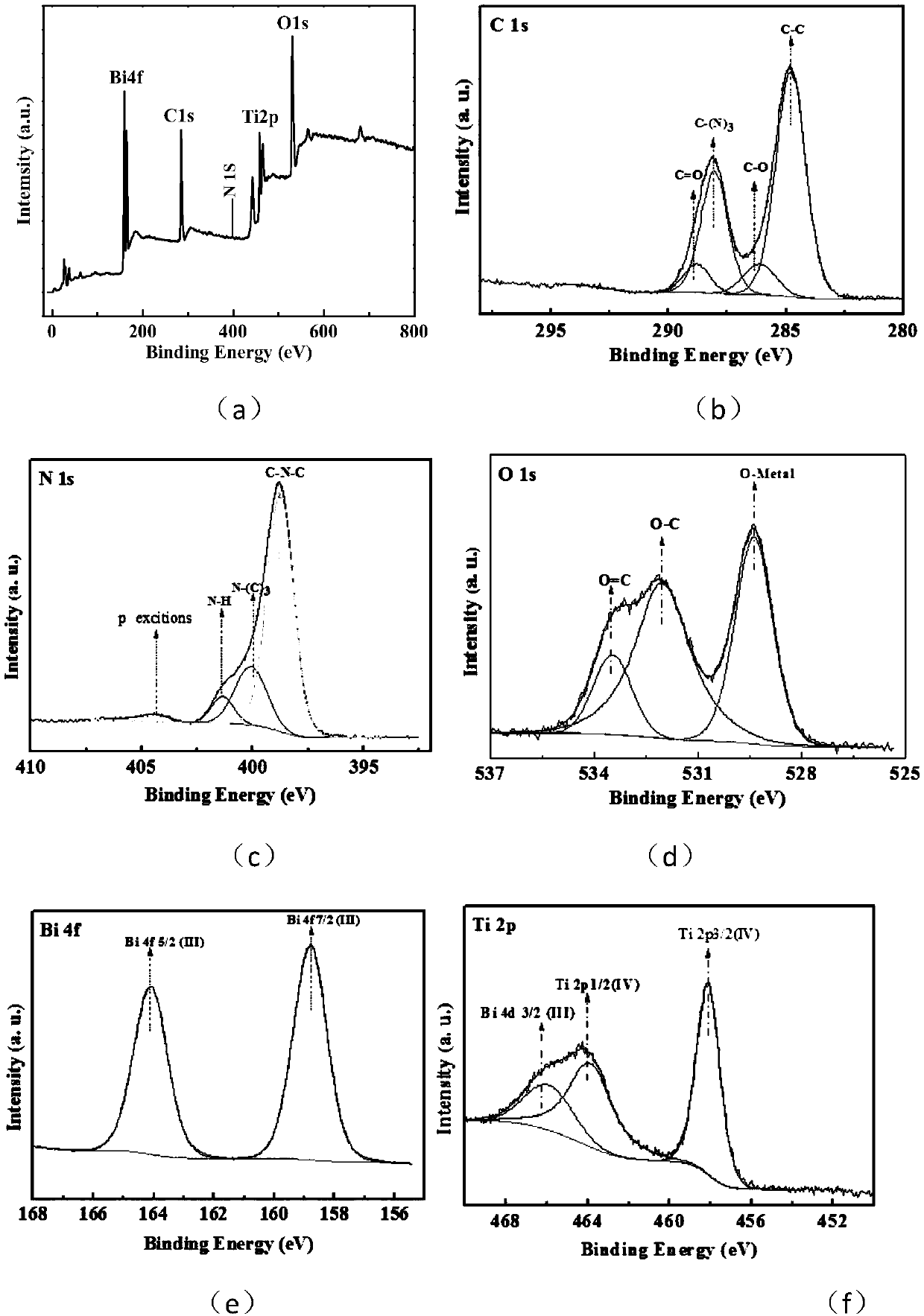

Image

Examples

preparation example Construction

[0032] A kind of preparation method of ternary semiconductor catalyst of the present invention, specifically carry out according to the following steps:

[0033] Step 1: Add 1 to 3 mmol of benzoyl peroxide to a mixture of 8 to 30 mL of acetone and 2-methoxyethanol and stir evenly; then add 0.2 to 0.5 mL of methacrylic acid and 0.4 ~ 1mL isopropyl titanate, continue to stir to obtain a light yellow solution;

[0034] Step 2,

[0035] Continue to add bismuth nitrate pentahydrate to the light yellow solution obtained in step 1, stir until the solution is uniform, and heat at 120°C for 60 minutes to obtain the precursor P 0 ;

[0036] Step 3,

[0037] In a 4kW ceramic fiber muffle furnace, react 0.8-2.0g of dicyandiamide at 540°C for 2h at a heating rate of 7°C / min, and naturally cool to room temperature to obtain light yellow g-C 3 N 4 ;

[0038] Step 4,

[0039] 1g precursor P obtained in step 2 0 Add to the g-C prepared in step 3 3 N 4 After grinding and mixing evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com