Nuclear reactor control rod loop chain production process

A technology for nuclear reactors and production processes, applied in manufacturing tools, furnace types, furnaces, etc., can solve the problems of unsatisfactory welding section size, low flash welding efficiency, deformation of anchor chain rings, etc. The effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

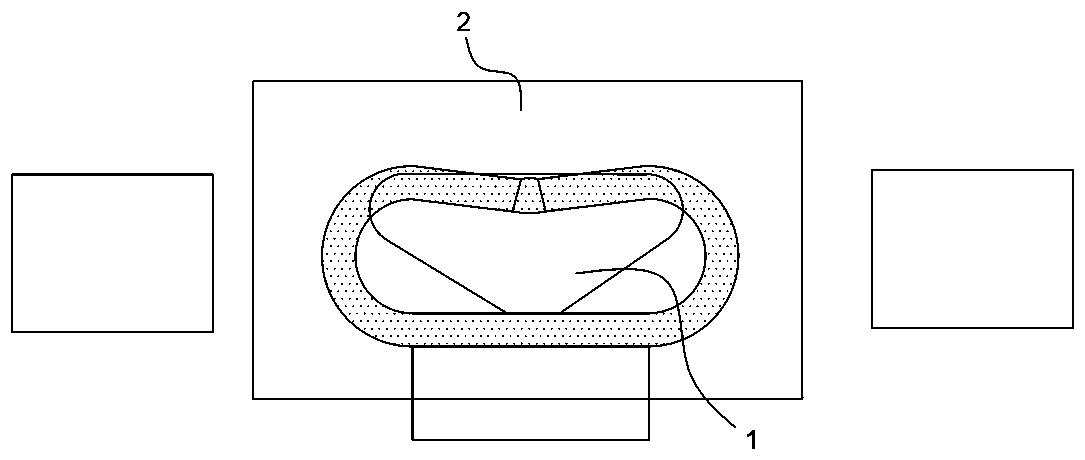

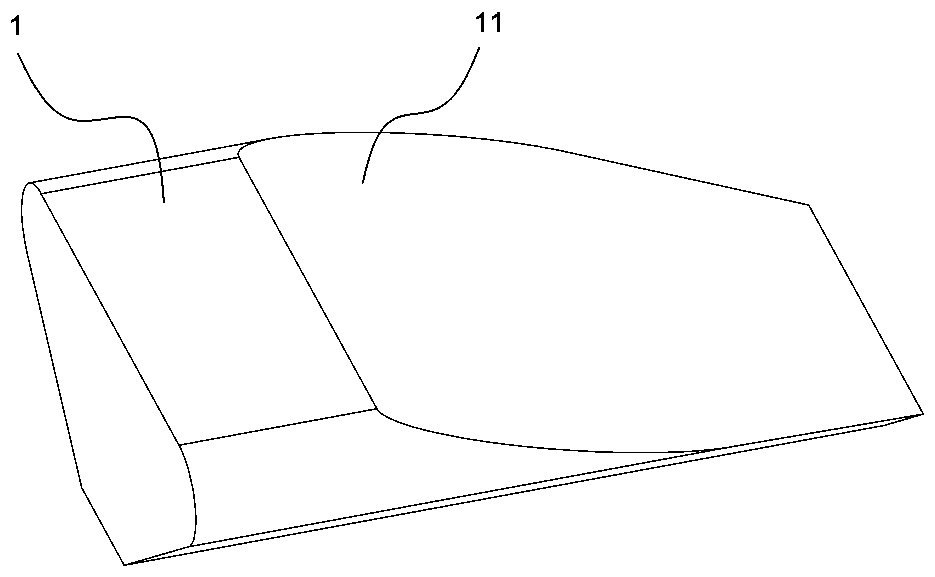

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with embodiment.

[0022] A nuclear reactor control rod chain production process, comprising the following steps:

[0023] Step 1, material preparation: the material used in the control rod chain is a nickel-chromium-molybdenum-niobium alloy rod, and the alloy material contains the following components in terms of mass percentage: C: ≤0.1%, Mn: ≤0.5%, Si: ≤0.5%, P: ≤0.015%, S: ≤0.015%, Cr: 20-23%, Nb+Ta: 3.15-4.15%, Co: ≤1%, Mo: 8-10%, Fe: ≤5% , Al: ≤0.4%, Ti: ≤0.4%, Ni: ≥58%.

[0024] Step 2, blanking: use a bar shear to cut the bar.

[0025] Step 3, knitting: install the designed and manufactured mandrel and other tooling on the chain knitting machine, heat the bar and knit it, and control the knitting temperature at 800-830°C.

[0026] Step 4: Shot blasting: use a shot blasting machine to blast the ring chain to make its surface reach the natural color of metal.

[0027] Step 5, welding: bend th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com