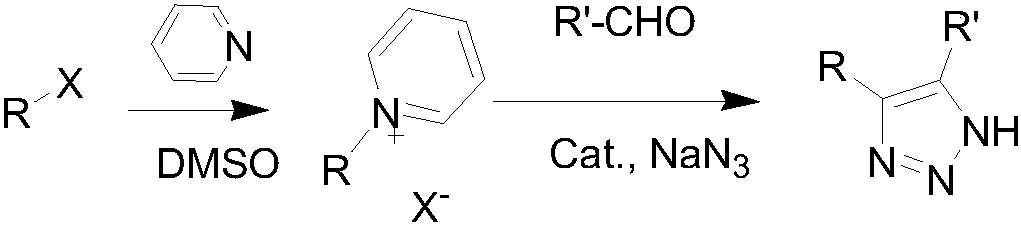

Method of preparing 4,5-disubstituted 1,2,3-triazole with pyridinium salt

A technology of triazole and disubstituted, which is applied in the field of preparation of 1,2,3-triazole compounds, can solve the problems of difficulty in synthesizing olefins and cannot be purchased, and achieves the effects of simple synthesis operation and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

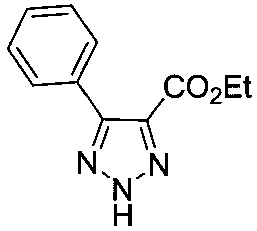

Embodiment 1

[0022] Ethyl α-bromoacetate (200mg, 1.2mmol) and pyridine (138mg, 1.8mmol) were dissolved in DMSO (5mL), stirred at room temperature for 5 hours. Then add benzaldehyde (191mg, 1.8mmol), NaN 3 (117mg, 1.8mmol) and L-proline (14mg, 0.12mmol), the reaction was stirred at room temperature. After the reaction was completed, the reaction solution was poured into ice water and extracted with ethyl acetate (20mL×4). The organic phases were combined, dried, and the solvent was removed under reduced pressure to obtain a crude product, which was separated and purified with a silica gel column to obtain 207 mg of the product, with a yield of 96%.

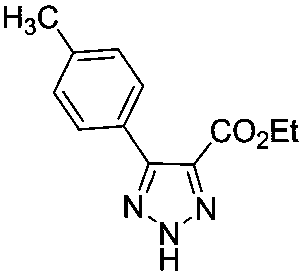

Embodiment 2

[0024] Ethyl α-bromoacetate (200mg, 1.2mmol) and pyridine (138mg, 1.8mmol) were dissolved in DMSO (5mL), stirred at room temperature for 5 hours. Then add benzaldehyde (191mg, 1.8mmol), NaN 3 (117mg, 1.8mmol) and serine (15mg, 0.12mmol), the reaction was stirred at room temperature. After the reaction was complete, the reaction solution was poured into ice water and extracted with ethyl acetate (20mL×4). The organic phases were combined, dried, and the solvent was removed under reduced pressure to obtain a crude product, which was separated and purified with a silica gel column to obtain 245mg of the product, with a yield of 94%.

Embodiment 3

[0026] Ethyl α-bromoacetate (200mg, 1.2mmol) and pyridine (138mg, 1.8mmol) were dissolved in DMSO (5mL), stirred at room temperature for 5 hours. Then add benzaldehyde (191mg, 1.8mmol), NaN 3 (117mg, 1.8mmol) and glycine (11mg, 0.12mmol), stirred at room temperature. After the reaction was completed, the reaction solution was poured into ice water and extracted with ethyl acetate (20mL×4). The organic phases were combined, dried and the solvent was removed under reduced pressure to obtain a crude product, which was separated and purified with a silica gel column to obtain 244 mg of the product, with a yield of 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com