Etching composition

A composition and etching technology, applied in the field of etching compositions, can solve problems such as increased defect rate, fast etching speed, etc., and achieve the effects of reducing brightness, increasing the number of etching treatment pieces, and suppressing residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1~6

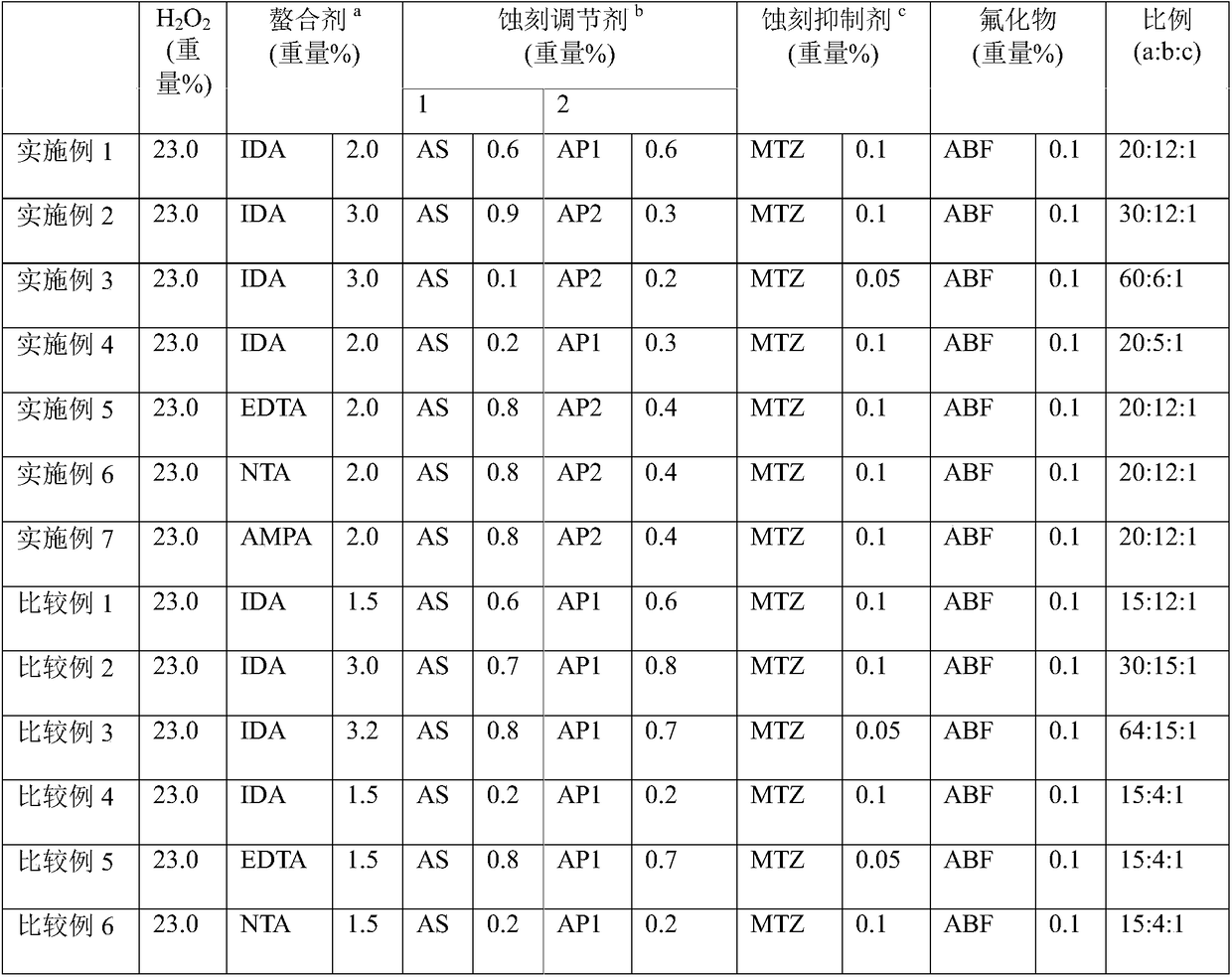

[0076] Each component of the composition described in Table 1 below was mixed to prepare etching compositions of Examples 1 to 7 and Comparative Examples 1 to 6 of the present invention.

[0077] [Table 1]

[0078]

[0079]

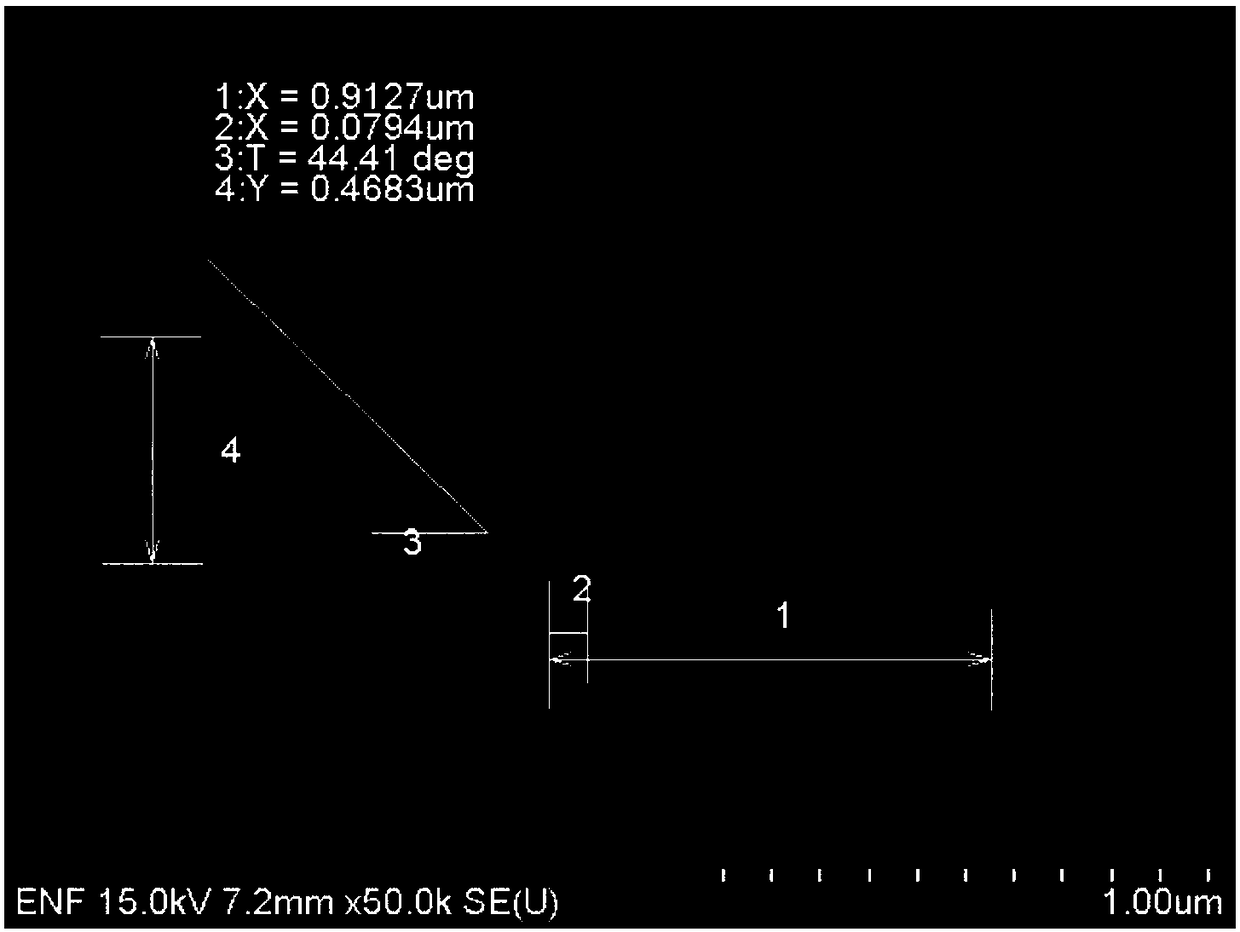

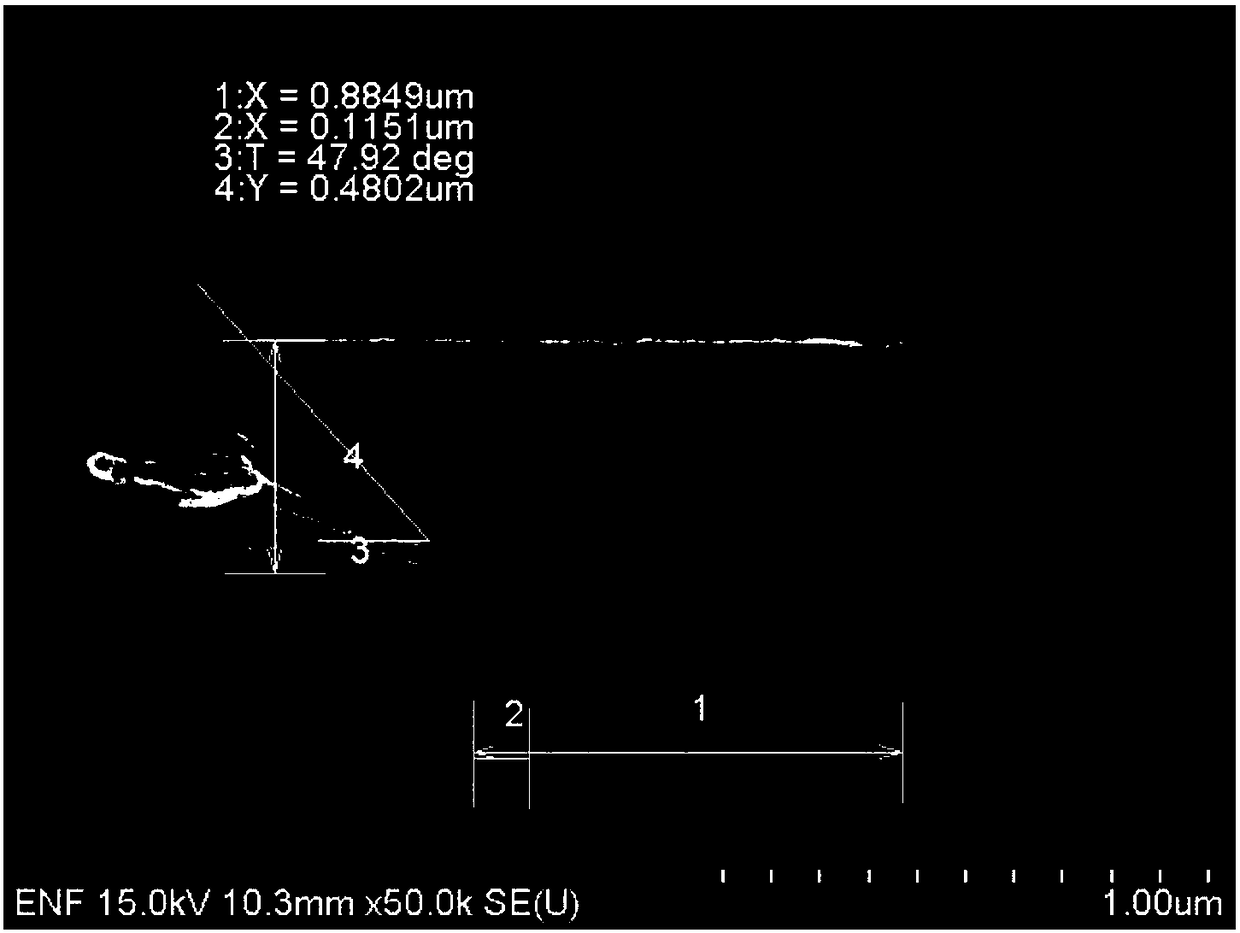

[0080] In order to evaluate the effect of the etching composition prepared by the above method, it was vapor-deposited with a barrier metal on a TFT-LCD GLS Molybdenum film, evaporated on it thick copper film, and then perform photolithography (Photolithography) process to form a pattern, thereby preparing a test piece. In order to confirm the etching characteristics (cone angle, etching deviation) of each etching composition, each test piece was etched with the EPD standard as 50% using a mini-etcher device, and copper powder was dissolved 300ppm and 5000ppm cumulatively in order to observe the number of etching treatments , 7000ppm and evaluation of the test piece, using a scanning electron microscope (manufactured by Hitachi, SU8010) observat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com