A device and method for online measurement of pH of neutralizing liquid with high temperature and strong scour

A measuring device and measuring method technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of difficult cleaning, poor use effect, untimely supply, etc., and achieve the effect of reducing test costs, improving work efficiency, and reducing consumption requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

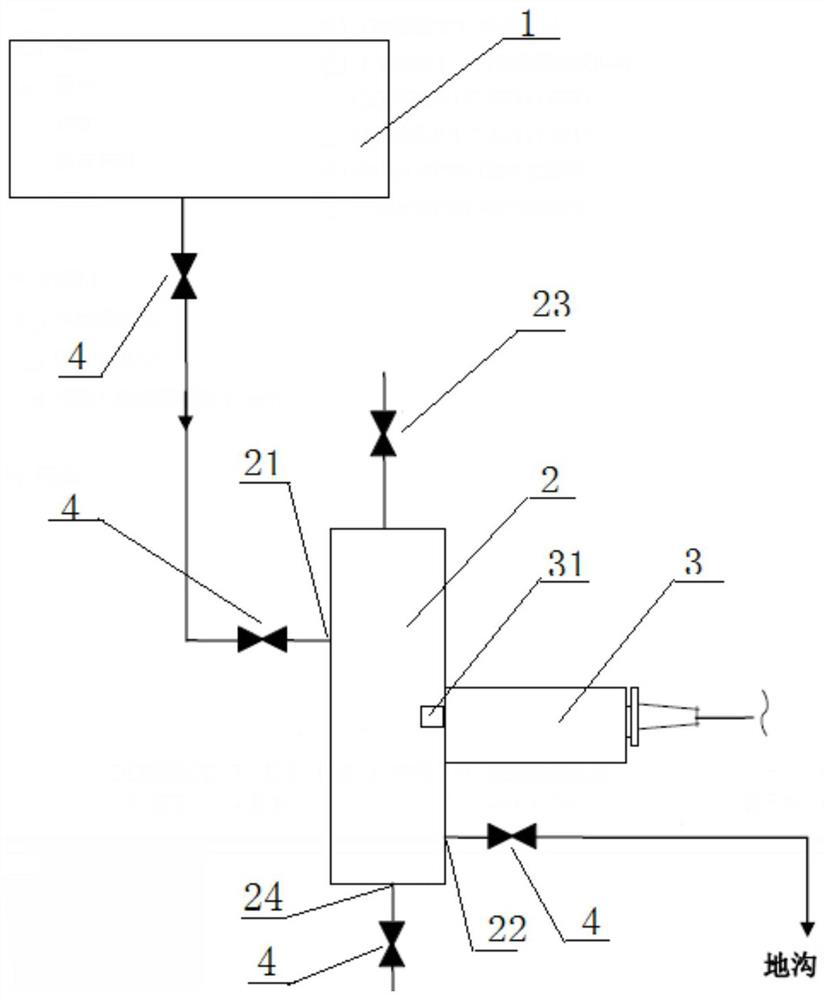

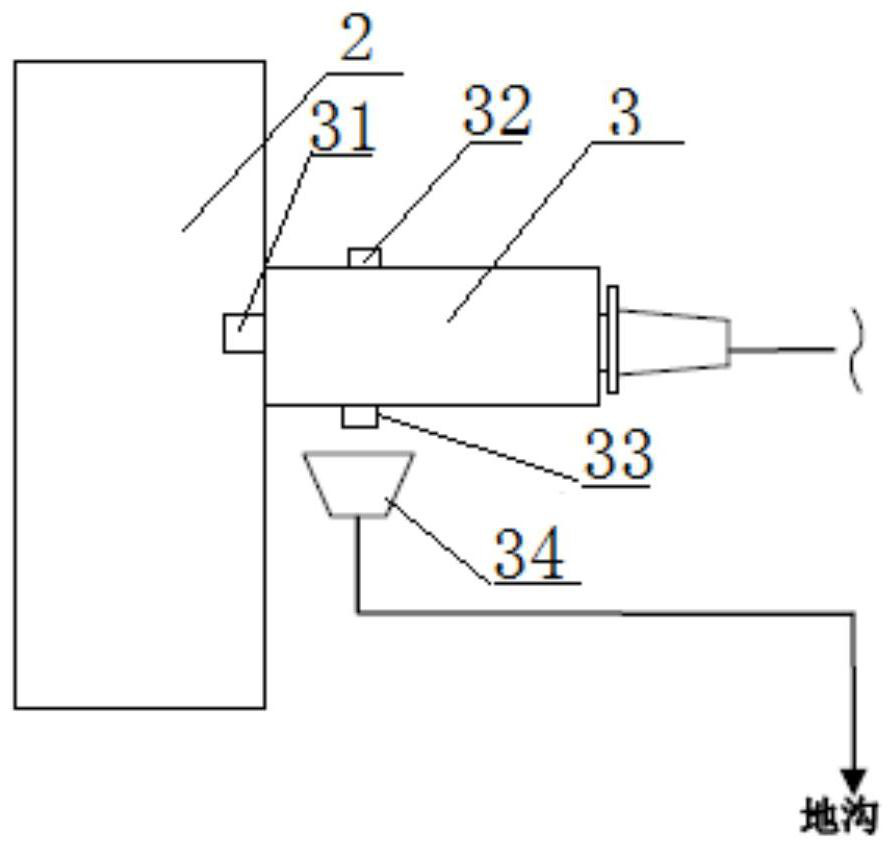

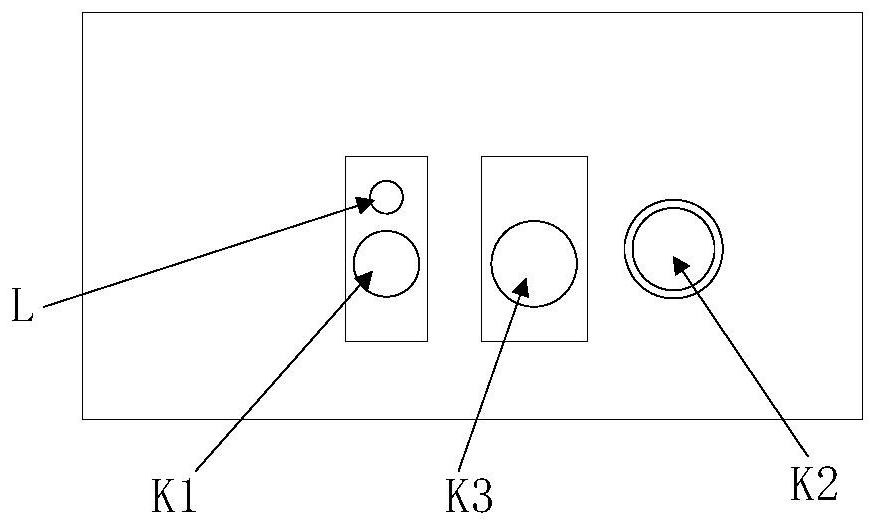

[0052] This embodiment provides a high-temperature strong scour neutralizing liquid pH online measuring device, such as figure 1 As shown in -5, it is used to measure the pH value of the neutralizing liquid discharged from the purification labyrinth mixing tank 1, which includes: a measuring sampling cylinder 2, a pH meter 31, a pneumatic telescopic protective cover 3 for fixing the pH meter 31, and a cleaning control device .

[0053] The measurement sampling cylinder 2 is provided with a water inlet 21, a water outlet 22, a test hole (not shown), a cut-off hole (not shown), and a sewage outlet 24; the water inlet 21 of the measurement sampling cylinder 2 passes through a water pipe and The purification labyrinth mixing tank 1 is connected, and the water outlet 22 of the measuring sampling cylinder 2 is connected to the trench through a water pipe. The cut-off hole (not shown) is provided with a shut-off valve 23, and the measuring sampling cylinder 2 is arranged on the groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com