Lead storage battery positive electrode plate taking 4BS-graphene as additive and preparation method of positive electrode plate

A lead-acid battery and graphene technology, applied in lead-acid battery electrodes, lead-acid batteries, battery electrodes, etc., can solve the problems of high conductivity of graphene, different current densities, graphene agglomeration, etc., and improve the charging acceptance of positive electrodes. ability, improve the ability to conduct current, improve the effect of discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

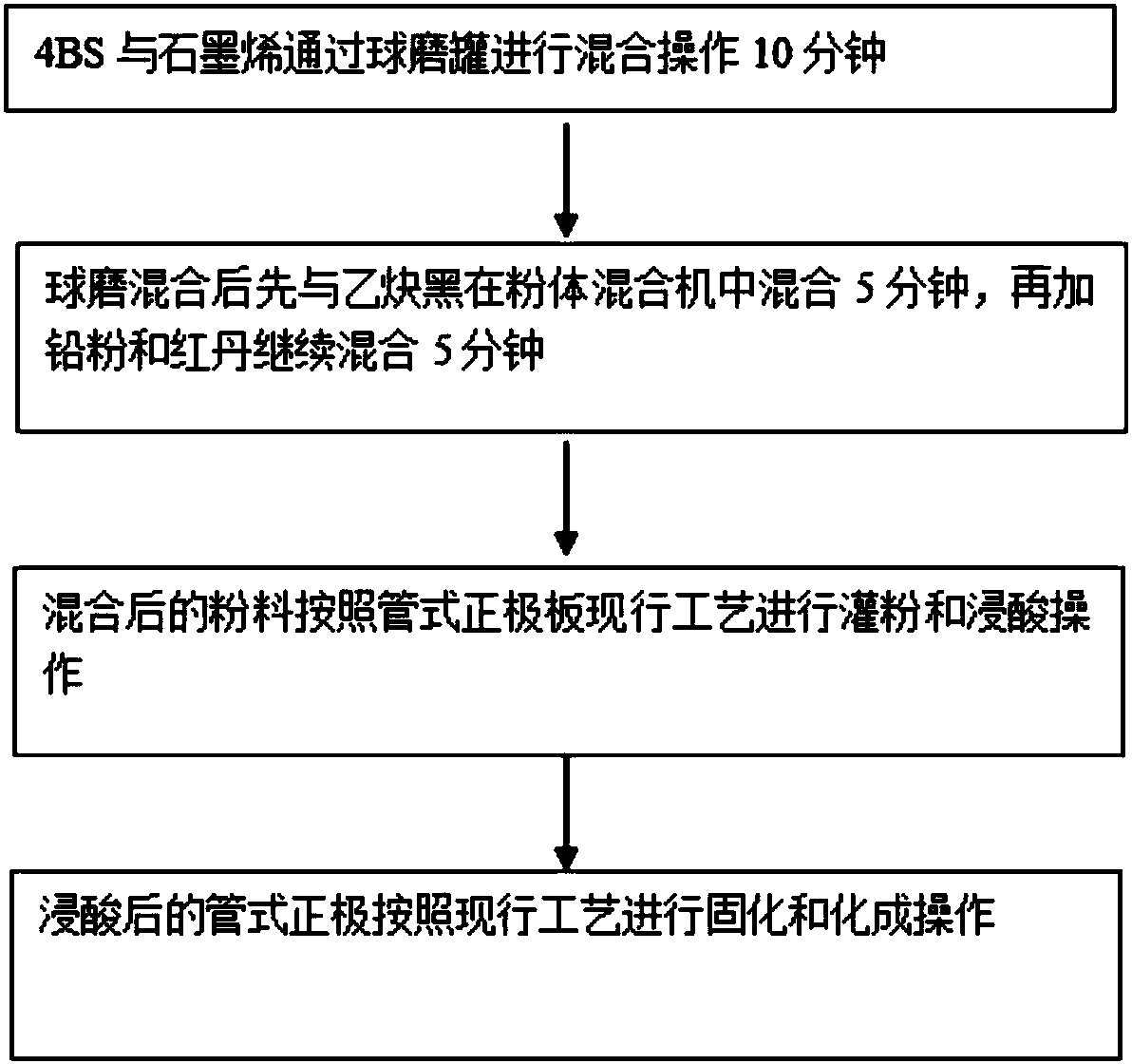

[0025] A kind of 4BS-graphene is used as the lead storage battery positive plate of additive and preparation method thereof and it comprises the following steps: S1, earlier 4BS and graphene are uniformly mixed 10 minutes in ball mill jar, then mix with certain amount of acetylene black 5 minutes, finally Mix with lead powder and red lead for 5 minutes to complete the powder mixing operation for the positive electrode of the lead battery. The proportions of the components in the positive electrode powder are: 4BS: 1.3%, graphene: 0.8%, acetylene black: 0.2% and red lead: 14%. , S2. Carry out powder filling, acid pickling, curing and chemical conversion operations on the positive electrode powder. The density of sulfuric acid for pickling the positive electrode powder is 1.1g / cm3, the curing temperature of the positive electrode is 65°C, and the thickness of graphene is <3nm. The particle size of ene is <15um, the length of 4BS is <15um, and the diameter of 4BS is <3um, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com