Sterilizing material containing protoporphyrin and preparation method and application thereof

A protoporphyrin and reaction technology, applied in the field of protoporphyrin-containing bactericidal materials and their preparation, can solve problems such as insolubility of protoporphyrin in water, and achieve the effects of low risk, good water solubility and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

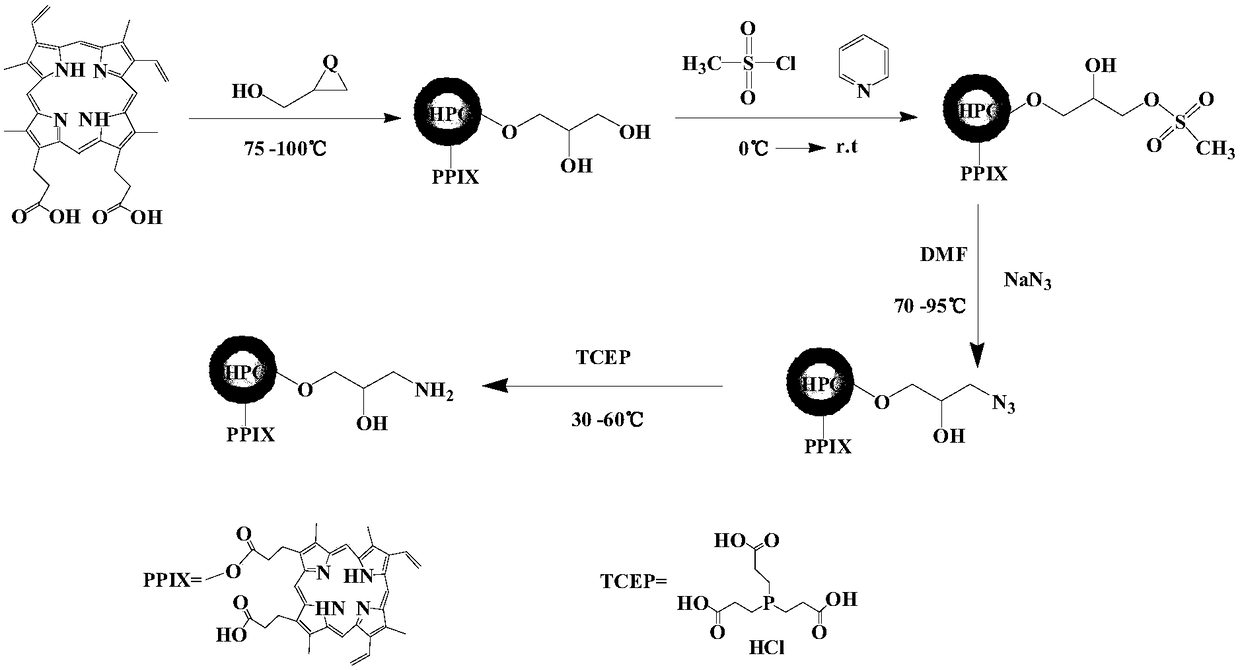

[0034] 1) Preparation of PPIX-HPG: react after mixing protoporphyrin and glycidol, then dialyze with pure water, and freeze-dry to obtain PPIX-HPG polymer;

[0035] 2) Preparation of PPIX-HPG-OMs: Dissolve the PPIX-HPG polymer in step 1) with pyridine, and at the same time use pyridine as a catalyst, add anhydrous methanesulfonyl chloride dropwise for mesylation, dialyze with ethanol, spin dry to prepare Obtain PPIX-HPG-Oms polymer;

[0036] 3) PPIX-HPG-N 3 Preparation: Dissolve the PPIX-HPG-OMs polymer in step 2) with DMF, react with sodium azide, and obtain PPIX-HPG-N after dialysis with pure water 3 polymer;

[0037] 4) PPIX-HPG-NH 2 Preparation: the PPIX-HPG-N in step 3) 3 The reduction reaction between the polymer and tris(2-carboxyethyl)phosphine hydrochloride reduces the azide group on the polymer to an amino functional group, and obtains PPIX-HPG-NH after water dialysis 2 Sterilizing material.

[0038] In step 1), it is characterized in that: in parts by weight, ...

Embodiment 1

[0044] PPIX-HPG-NH 2 The preparation method of sterilizing material 1, comprises the following steps:

[0045] 1) Preparation of PPIX-HPG: Weigh 90mg of protoporphyrin and 5mL of glycidol, mix and react at 75°C for 36h, then, when the product is cooled to room temperature, put the product into a 3500D dialysis bag and dialyze with deionized water, and the dialysis is completed After filtering with a 0.22 μm pinhole filter, the initial product PPIX-HPG can be obtained;

[0046] 2) Preparation of PPIX-HPG-OMs: Dissolve the PPIX-HPG polymer in step 1) with pyridine, and at the same time use pyridine as a catalyst, add anhydrous methanesulfonyl chloride dropwise for mesylation, react at room temperature for 24h, mol Ratio PPIX-HPG:Ms=1:0.5, dialyzed through ethanol, spin-dried;

[0047] 3) PPIX-HPG-N 3Preparation: Dissolve the PPIX-HPG-OMs polymer in step 2) with DMF, react with sodium azide at 70°C for 36h, the molar ratio is 1:1, wait for the product to cool down to room temp...

Embodiment 2

[0050] PPIX-HPG-NH 2 The preparation method of sterilizing material 2, comprises the following steps:

[0051] 1) Preparation of PPIX-HPG: Weigh 120mg of protoporphyrin and 5mL of glycidol and mix them and react at 85°C for 36h. After the product cools down to room temperature, put the product into a 3500D dialysis bag and dialyze with deionized water. After the dialysis is completed, use The initial product PPIX-HPG can be obtained by filtering through a 0.22 μm pinhole filter;

[0052] 2) Preparation of PPIX-HPG-OMs: Dissolve the PPIX-HPG polymer in step 1) with pyridine, and at the same time use pyridine as a catalyst, add anhydrous methanesulfonyl chloride dropwise for mesylation, react at room temperature for 24h, mol Ratio PPIX-HPG:Ms=1:1.2, dialyzed through ethanol, spin-dried;

[0053] 3) PPIX-HPG-N 3 Preparation: Dissolve the PPIX-HPG-OMs polymer in step 2) with DMF, react with sodium azide at 85°C for 36h, the molar ratio is 1:0.5, wait for the product to cool dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com