Waterborne PET silk screen ink and preparation method thereof

A screen printing ink, water-based technology, applied in the field of water-based PET screen printing ink and its preparation, can solve the problem of further improvement in adhesion performance, and achieve the effects of excellent leveling, low odor, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

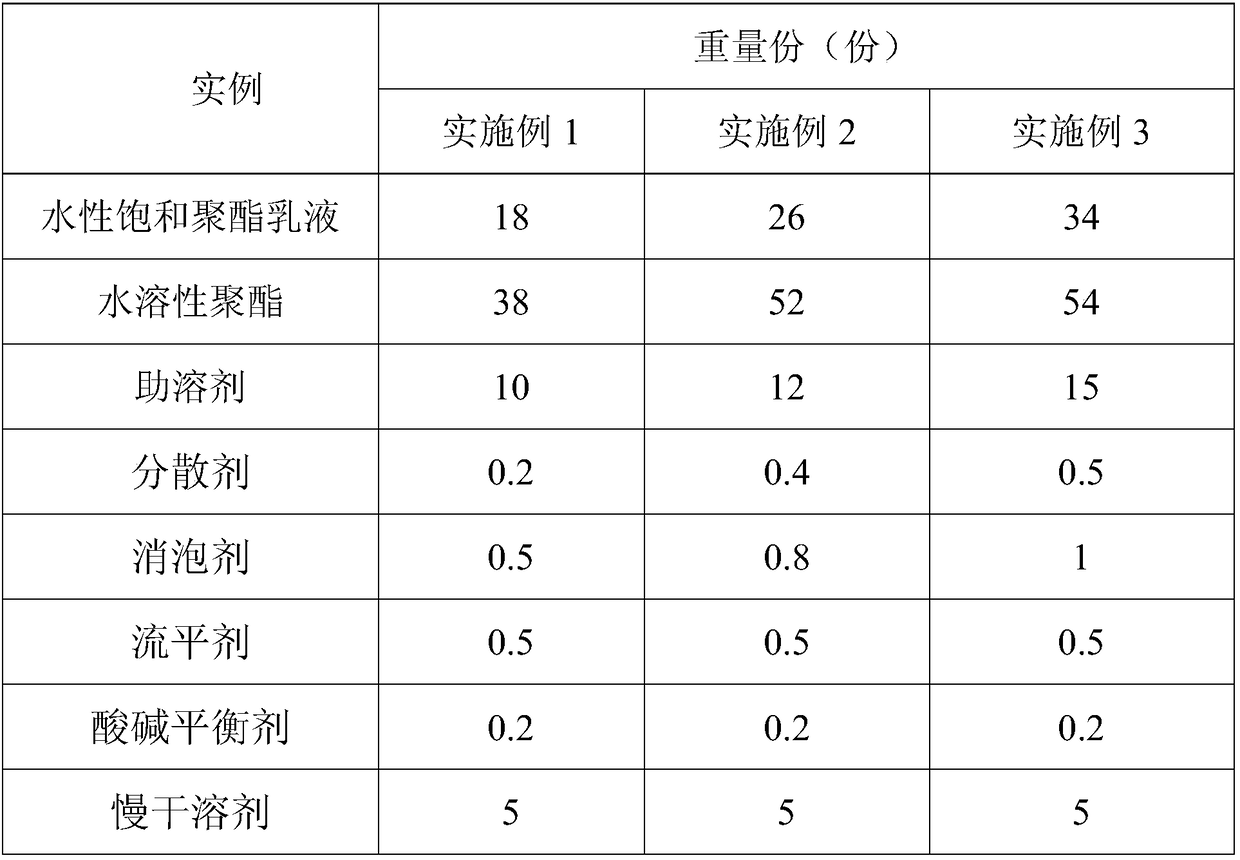

[0045] The technical solutions of the present invention will be further described below through specific embodiments.

[0046] Unless specifically stated, various raw materials of the present invention can be purchased commercially, or can be prepared according to conventional methods in the art.

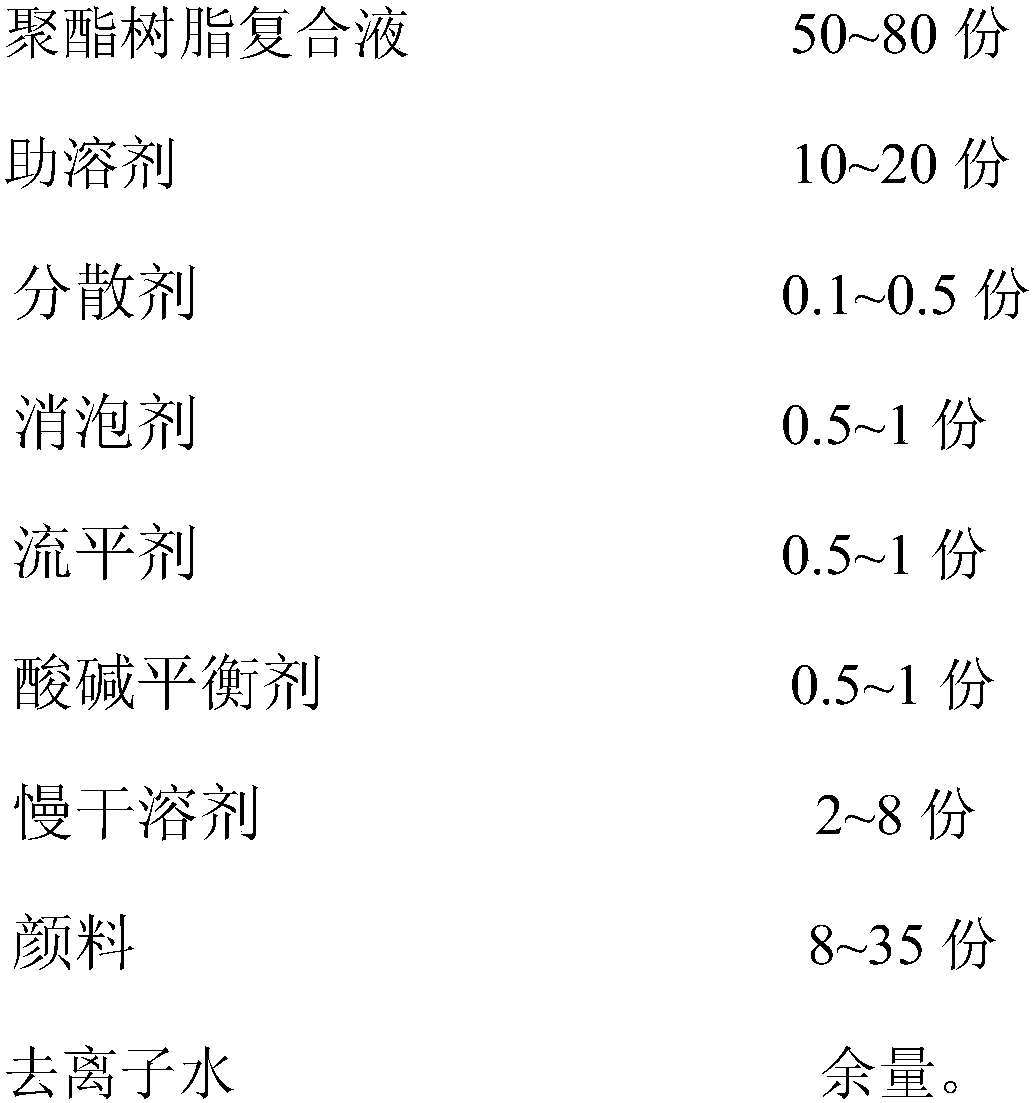

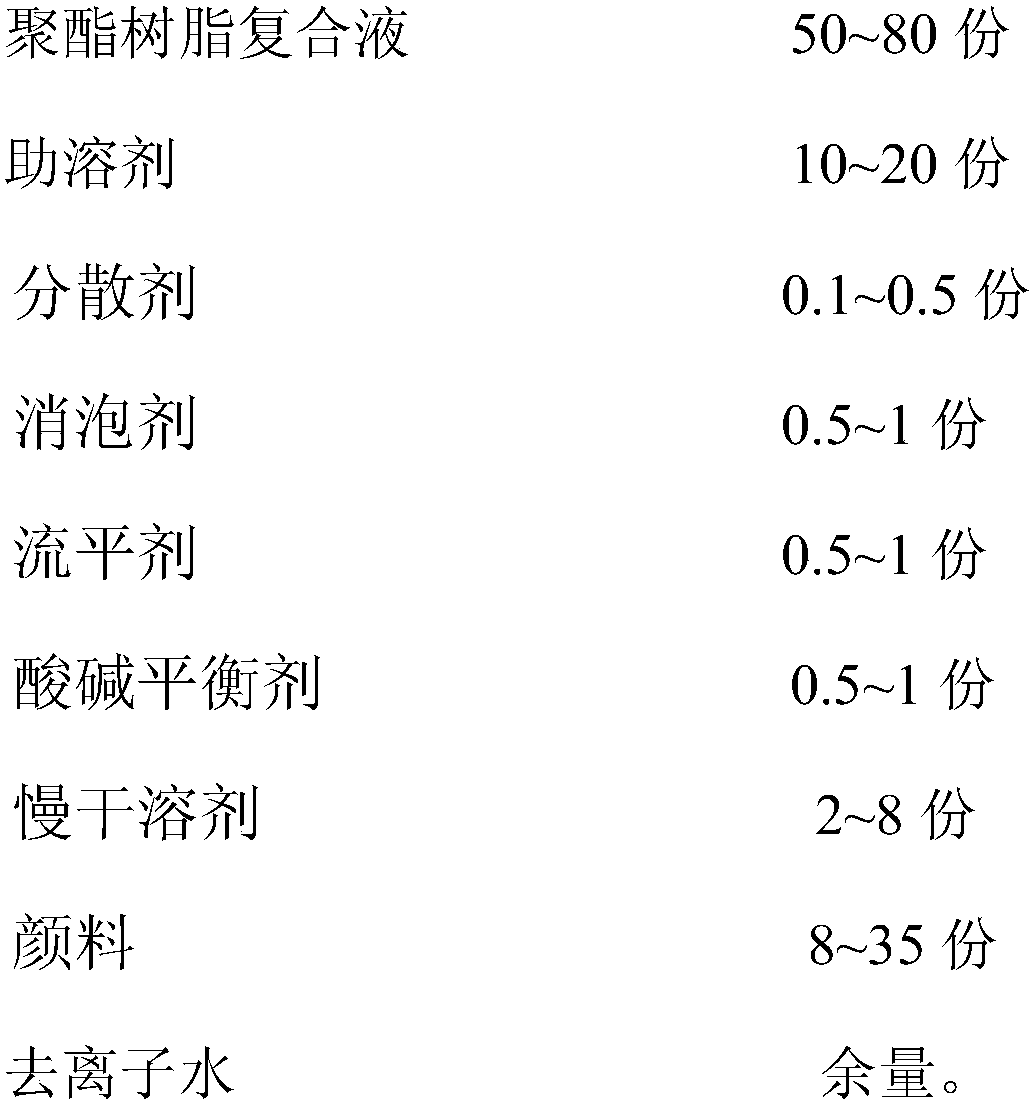

[0047] Water-based PET screen printing ink of the present invention, by weight, the preparation raw material of described water-based PET screen printing ink comprises following components:

[0048]

[0049] The preparation method of water-based PET screen printing ink of the present invention comprises the steps:

[0050] 1) In parts by weight, add 10-20 parts of co-solvent, 50-80 parts of polyester resin compound liquid, deionized water, and stir to dissolve;

[0051] 2) In parts by weight, add 0.1 to 0.5 parts of dispersant, 0.5 to 1 part of leveling agent, 0.5 to 1 part of defoamer, and 0.5 to 1 part of acid-base to the mixture obtained in step 1). Balancer, 2-8 parts of sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com