Device and method for rapid cooling of organic silicone sealant

A rapid cooling and sealant technology, applied in chemical instruments and methods, adhesives, educts, etc., can solve the problems of unsatisfactory cooling effect, low production efficiency, and high motor energy consumption, and achieve easy operation control and improve production efficiency. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

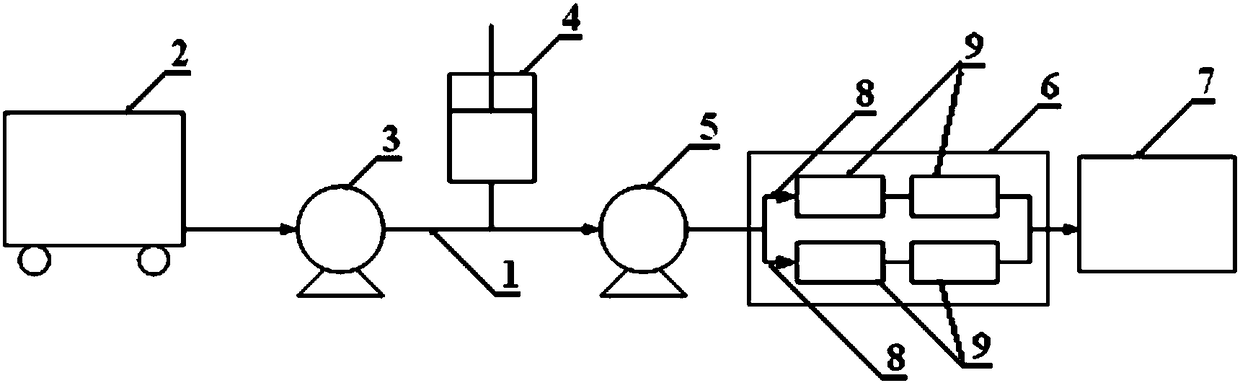

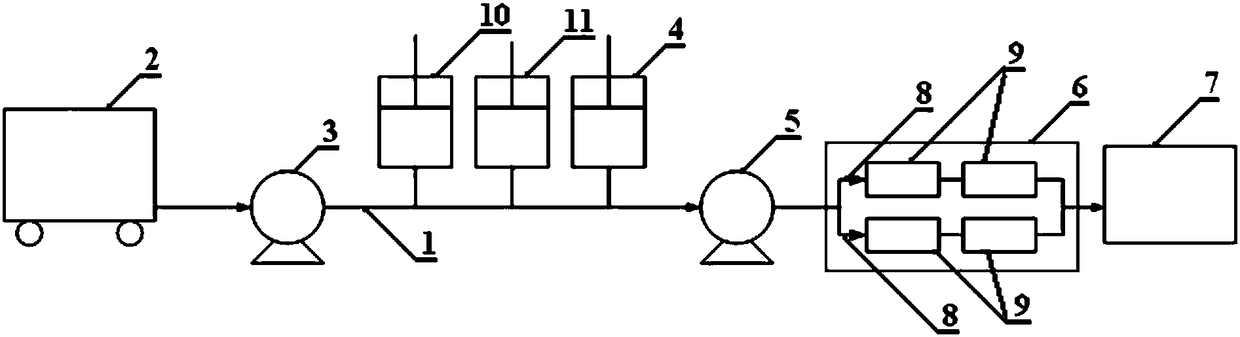

[0055] see figure 2 , figure 2 Schematic diagram of the structure of the device for rapid cooling of silicone sealant provided in Example 1 of the present invention. Among them, 1 is the material conveying pipeline, 2 is the kneader, 3 is the first booster pump, 4 is the first buffer tank, 5 is the second booster pump, 6 is the condensation device, 7 is the stirring tank, and 8 is the condensation 9 is a cooling pipe, 10 is a second buffer tank, and 11 is a third buffer tank.

[0056] The specific working process of the device for the rapid cooling of the silicone sealant provided by embodiment 1 is:

[0057] (1) Under the pressure provided by the first booster pump, the base material in the kneader is discharged, and the flow rate of the material is 2.5m 3 / h, enter the first buffer tank, the second buffer tank and the third buffer tank respectively through the material conveying pipeline; the temperature of the base material is 90°C.

[0058] (2) Under the pressure pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com