Microwave-activation-based core-shell catalyst for preparing synthesis gas through methane CO2 reforming, and preparation method thereof

A core-shell catalyst and synthesis gas technology, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, hydrogen/synthesis gas production, etc., can solve the problems of high preparation costs, complicated preparation methods, and Promote the application of catalysts and other issues to achieve the effects of improving anti-sintering performance, inhibiting carbonation, and inhibiting the growth of Ni particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

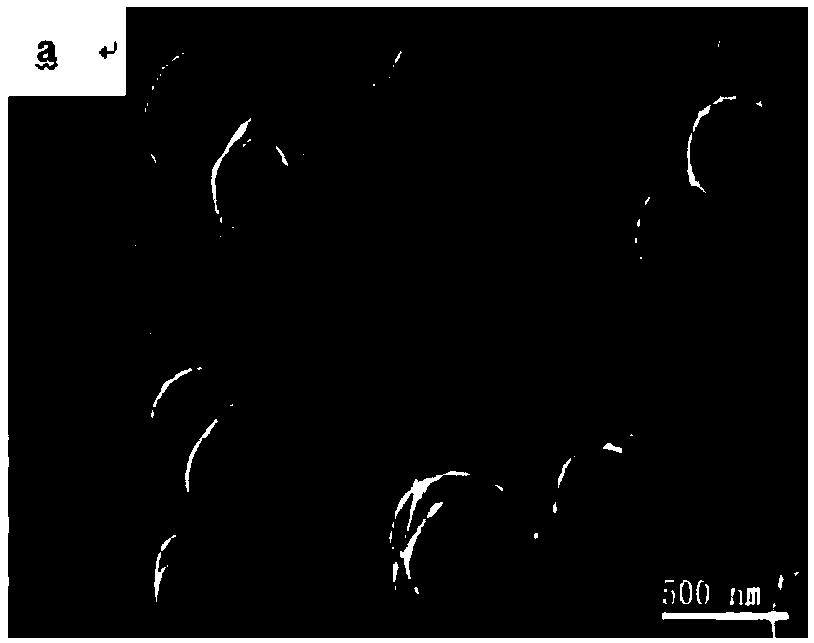

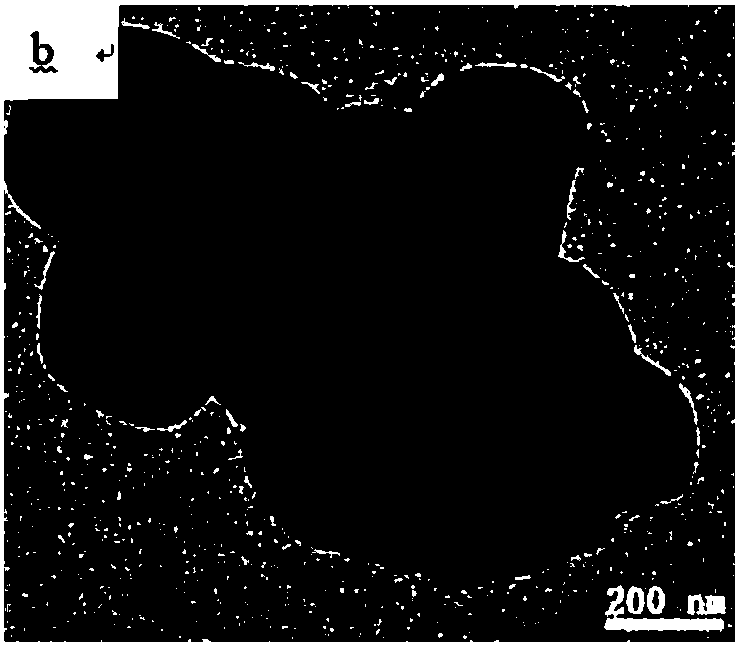

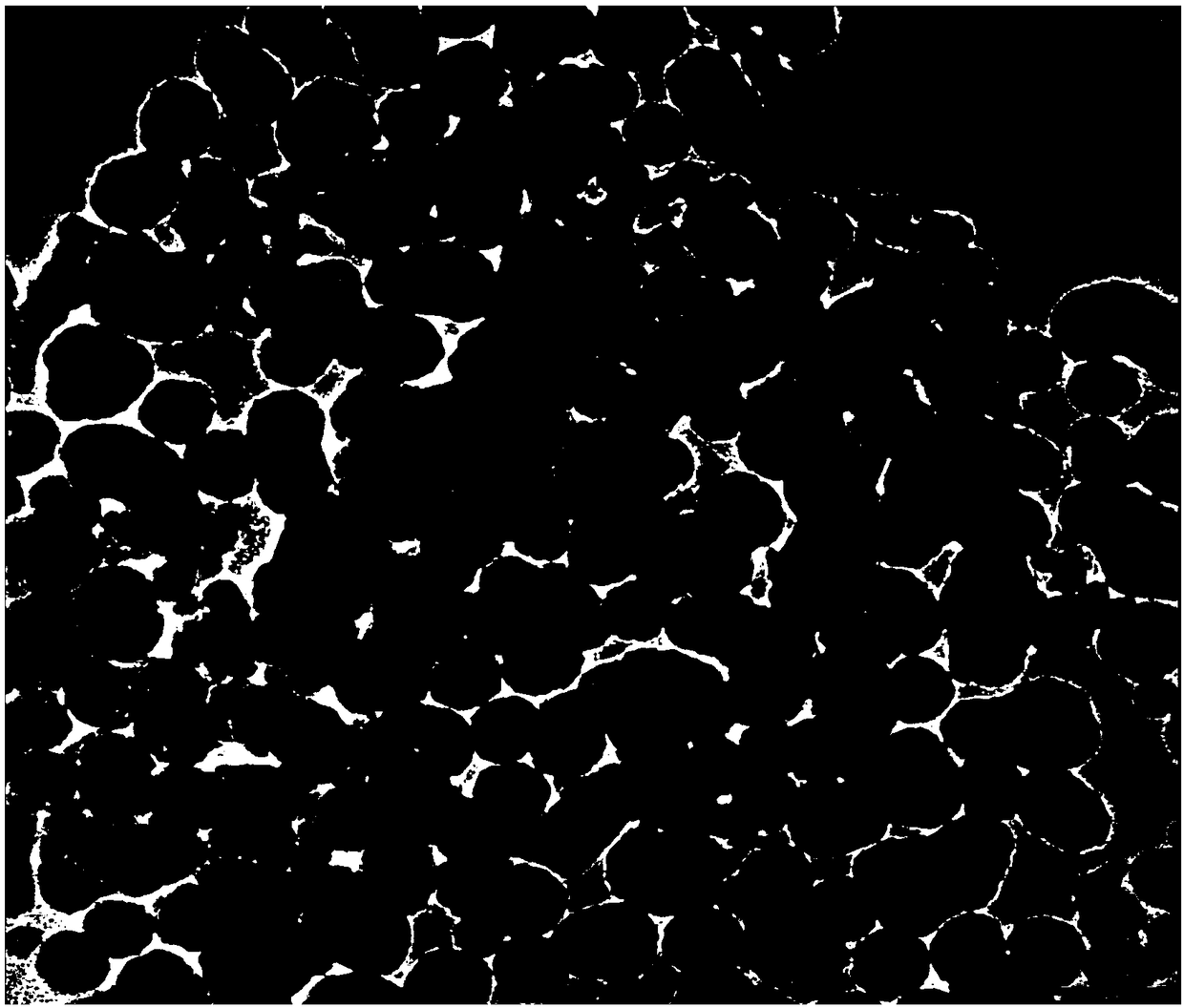

[0090] This example provides a microwave-activated methane CO 2 Reforming synthetic gas core-shell catalyst, the core of the core-shell catalyst is composed of a substrate and a metal Ni active component loaded on the substrate, and the shell is composed of a carbon layer from the inside to the outside and a porous microwave absorbing layer;

[0091] Wherein, the matrix is ordered mesoporous Al 2 o 3 -MgO composite metal oxide (and Al 2 o 3 Accounting for 10% to 90% of the total mass of the substrate), the porous microwave absorbing layer is ZnO-Fe 2 o 3 Composite transition metal oxide layer (and ZnO accounts for 1% to 99% of the total mass of the porous microwave absorbing layer);

[0092] Also, the ratio of the sum of atoms of Zn and Fe in the outer shell to the sum of atoms of Al and Mg in the inner core is 1:1.

[0093] The preparation method of the core-shell catalyst of the present embodiment comprises the following steps:

[0094] 1. Preparation of ordered mes...

Embodiment 2

[0104] The difference between this embodiment and embodiment 1 is:

[0105] In core-shell catalysts, the matrix is ordered mesoporous Al 2 o 3 -CaO, and the porous microwave absorbing layer is a ZnO-CuO composite transition metal oxide layer.

[0106]The core-shell catalyst obtained in this example was tested, and the results showed that its morphology and methane conversion performance were similar to those in Example 5.

Embodiment 3

[0108] The difference between this embodiment and embodiment 1 is:

[0109] In core-shell catalysts, the matrix is ordered mesoporous Al 2 o 3 -SrO, and the porous microwave absorbing layer is TiO 2 -Sm 2 o 3 Composite transition metal oxide layer.

[0110] The core-shell catalyst obtained in this example was tested, and the results showed that its morphology and methane conversion performance were similar to those in Example 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com