Ultra-thin bismuth oxyhalide nanosheet as well as preparation and application thereof

A technology of bismuth oxyhalide and nanosheets is applied in the field of photocatalysis, which can solve the problems that have not yet been found, and achieve the effects of reducing the electron-hole recombination rate, improving the utilization rate, and improving the catalytic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

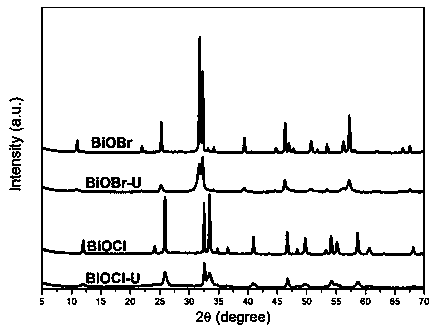

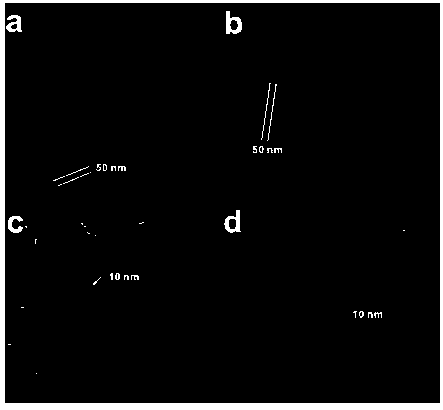

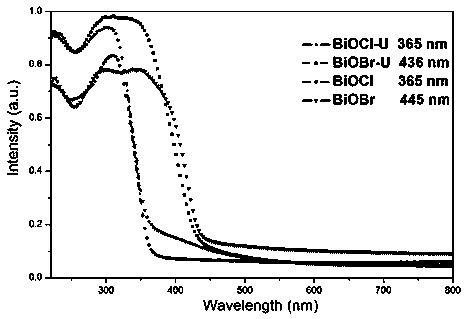

Embodiment 1

[0026] (1) Weigh 0.019g of guar gum and 9.701g of bismuth nitrate pentahydrate, mix them evenly and grind for 30min to obtain the precursor;

[0027] (2) Slowly add the precursor prepared above into 10ml potassium chloride aqueous solution with a concentration of 0.01mol / L, mix and stir evenly to obtain a paste liquid;

[0028] (3) Transfer the pasty liquid to a 500ml flask, add 180ml of water, then stir and react at 30°C for 3h to obtain the product, then wash and dry the product to obtain ultrathin bismuth oxychloride nanosheets.

Embodiment 2

[0030] (1) Weigh 0.097g of guar gum and 9.701g of bismuth nitrate pentahydrate, mix them evenly and grind for 35min to obtain the precursor;

[0031] (2) Slowly add the above-prepared precursor into 10ml potassium bromide aqueous solution with a concentration of 0.05mol / L, mix and stir evenly to obtain a pasty liquid;

[0032] (3) Transfer the pasty liquid to a 500ml flask, add 190ml of water, then stir and react at 45°C for 3.5h to obtain the product, then wash and dry the product to obtain ultrathin bismuth oxybromide nanosheets.

Embodiment 3

[0034] (1) Weigh 0.146 g of guar gum and 9.701 g of bismuth nitrate pentahydrate, mix them evenly and grind for 40 minutes to obtain the precursor;

[0035] (2) Slowly add the precursor prepared above into 10ml potassium chloride aqueous solution with a concentration of 0.08mol / L, mix and stir evenly to obtain a paste liquid;

[0036] (3) Transfer the pasty liquid to a 500ml flask, add 200ml of water, then stir and react at 65°C for 4h to obtain the product, then wash and dry the product to obtain ultrathin bismuth oxychloride nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com