Maltol chlorination reaction heat exchange method

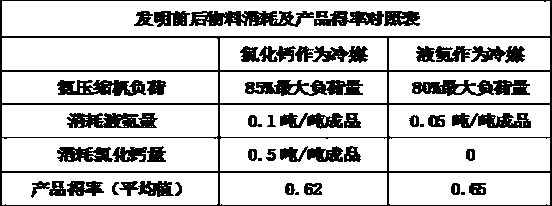

A chlorination reaction and maltol technology, applied in the direction of organic chemistry, etc., can solve the problems of unstable product yield, large heat exchange heat loss, large ammonia compressor load, etc., to eliminate the risk of environmental pollution and reduce heat exchange. Heat loss, the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

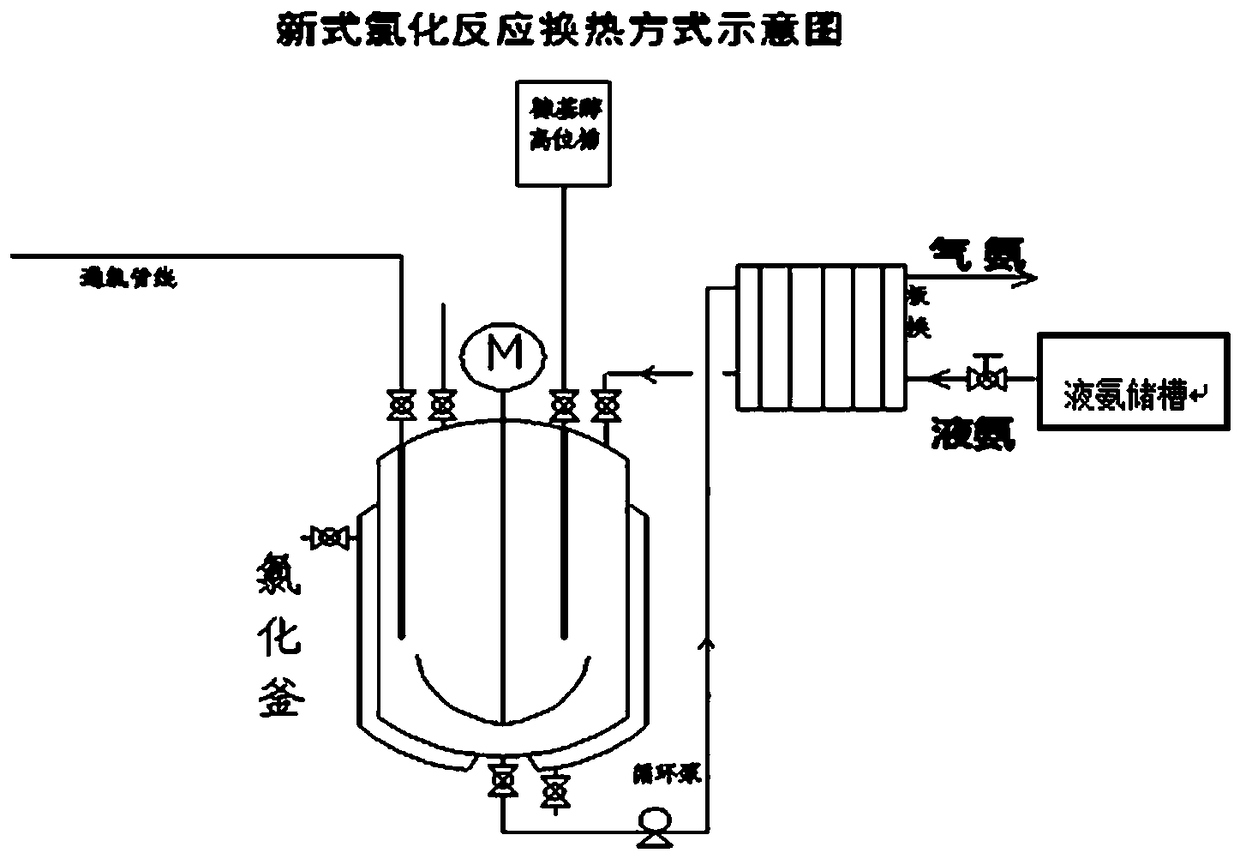

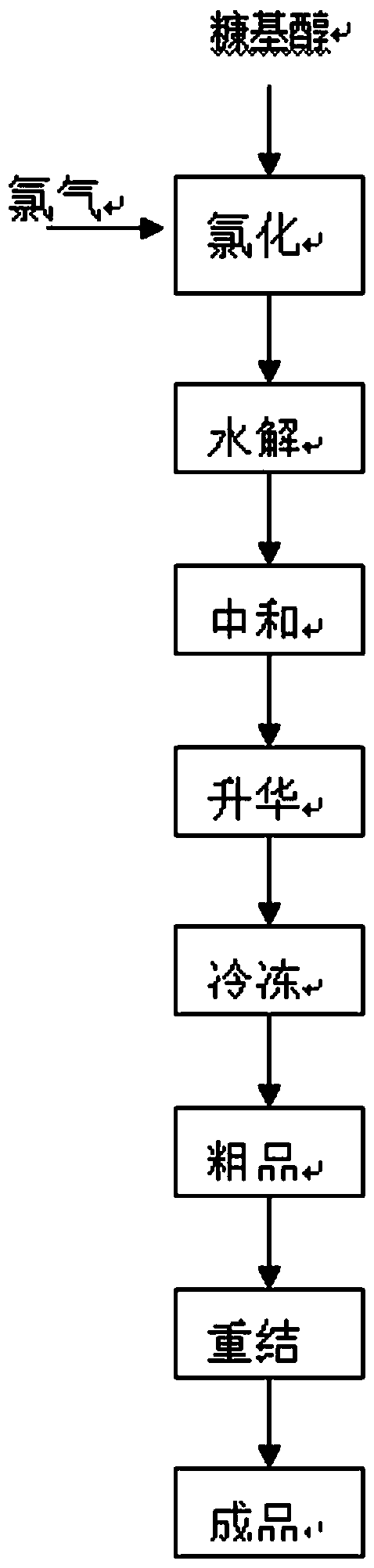

[0020] Pump 3,500 liters of 50% methanol aqueous solution into the chlorination kettle, turn on the circulation pump, make the methanol aqueous solution circulate continuously in the chlorination kettle and plate exchange, replace the refrigerant with liquid ammonia, and control the pressure of the liquid ammonia storage tank to 1.0-1.5 Mp, open the ammonia valve to feed liquid ammonia, use the principle of evaporation, vaporization and heat absorption of liquid ammonia, let the liquid ammonia directly vaporize and absorb heat in the plate exchange, directly cool the reaction materials, control the gas phase pressure of the ammonia gas outlet at 0.3Mpa, and Use the ammonia valve to adjust the amount of liquid ammonia, so that the temperature of the chlorination tank is not higher than -10°C during the reaction. When the temperature of the methanol solution in the chlorination tank drops to -15°C, start to add furfuryl alcohol and bran Base alcohol rate of addition is 125kg / h, f...

example 2

[0022] Pump 3,500 liters of 50% methanol aqueous solution into the chlorination kettle, turn on the circulation pump, make the methanol aqueous solution circulate continuously in the chlorination kettle and plate exchange, replace the refrigerant with liquid ammonia, and control the pressure of the liquid ammonia storage tank to 1.0-1.5 Mp, open the ammonia valve to feed liquid ammonia, use the principle of evaporation, vaporization and heat absorption of liquid ammonia, let the liquid ammonia directly vaporize and absorb heat in the plate exchange, directly cool the reaction materials, control the gas phase pressure of the ammonia gas outlet at 0.3Mpa, and Use the ammonia addition valve to adjust the amount of liquid ammonia introduced so that the temperature of the chlorination tank is not higher than -12°C during the reaction. When the temperature of the methanol solution in the chlorination tank drops to -15°C, start to drop furfuryl alcohol, Base alcohol drop rate is 100kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com