House structure

A house and frame technology, applied in building structure, adhesive additives, construction, etc., can solve the problems of low construction efficiency, waste of use area, large occupied area, etc., and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

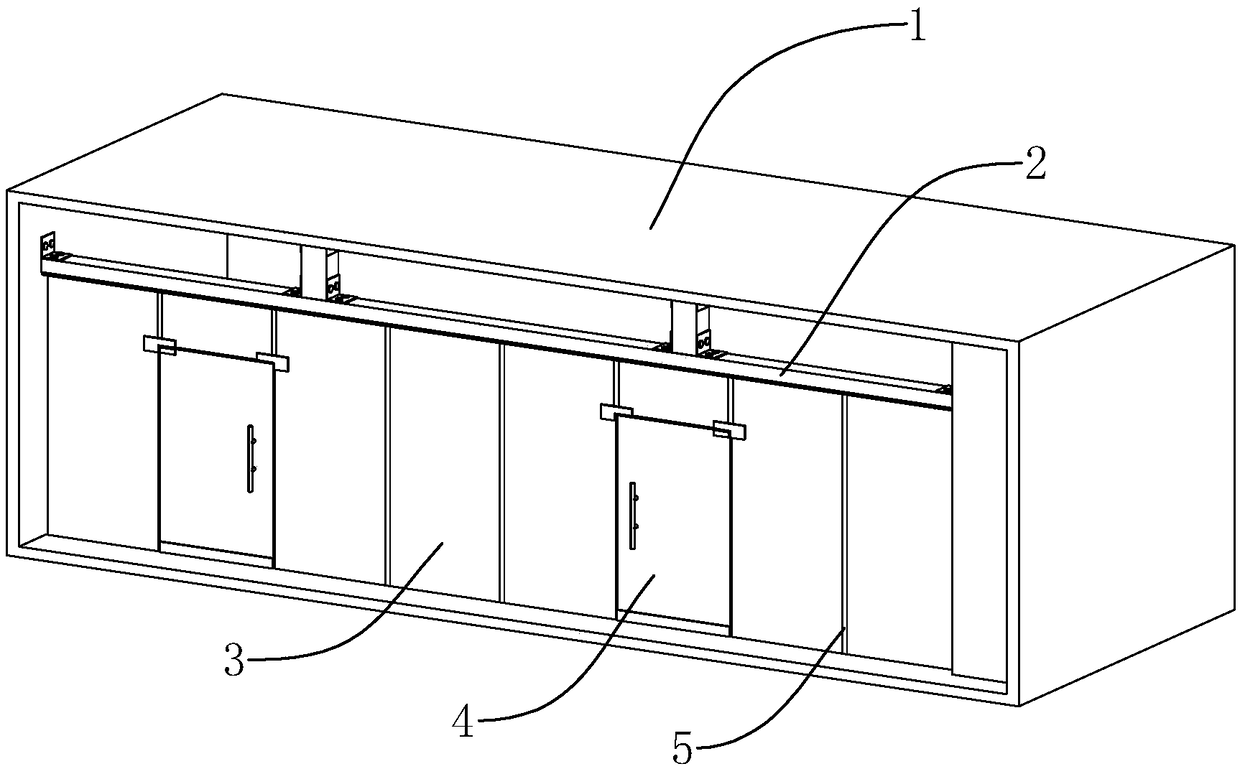

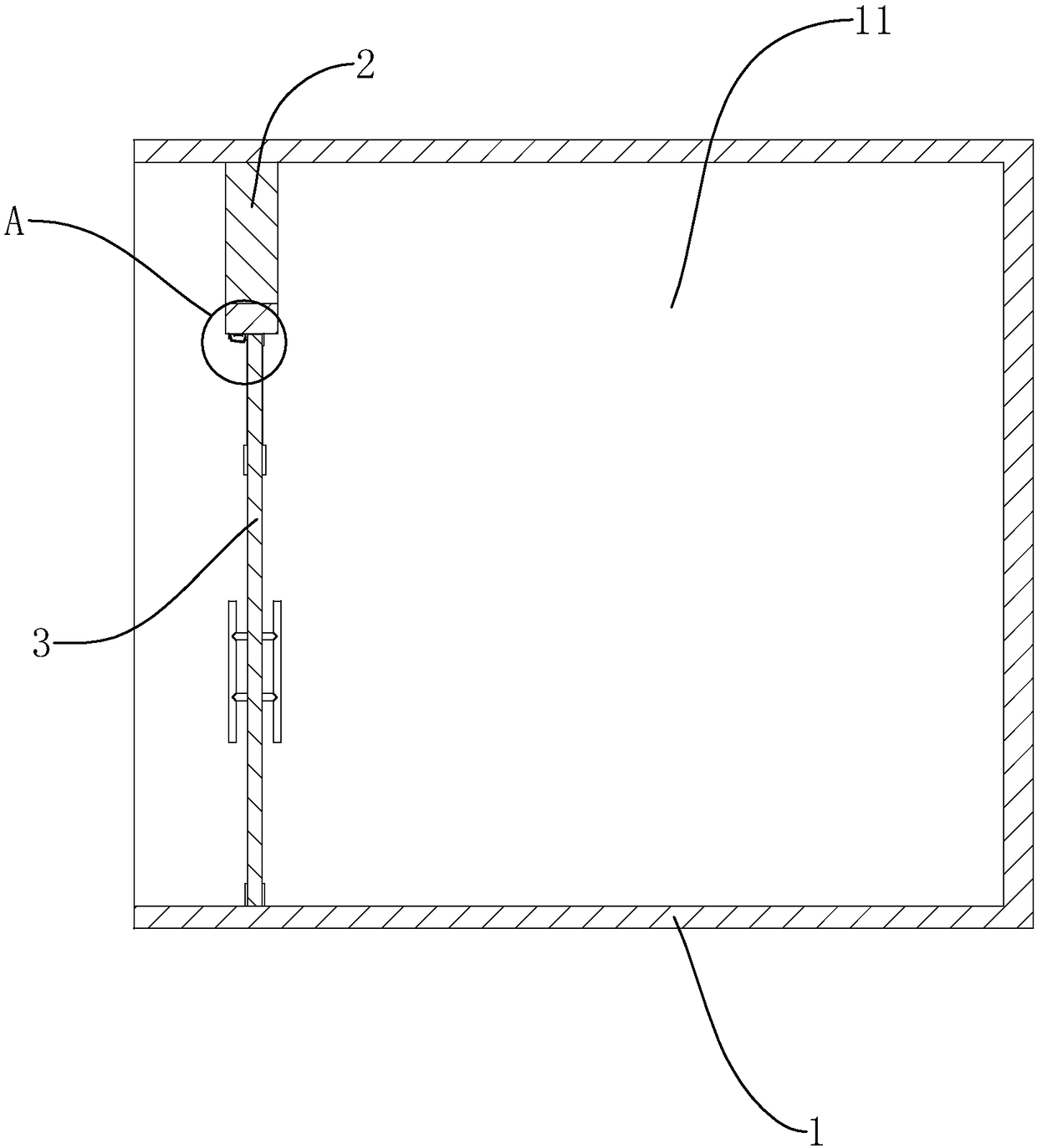

[0042] Such as figure 1 As shown, a house structure includes a house frame 1 . Inside the house frame 1 is provided an upper pole 2 whose two ends are respectively fixedly connected to the wall of the house frame 1 and whose upper side is fixedly connected to the ceiling of the house frame 1 .

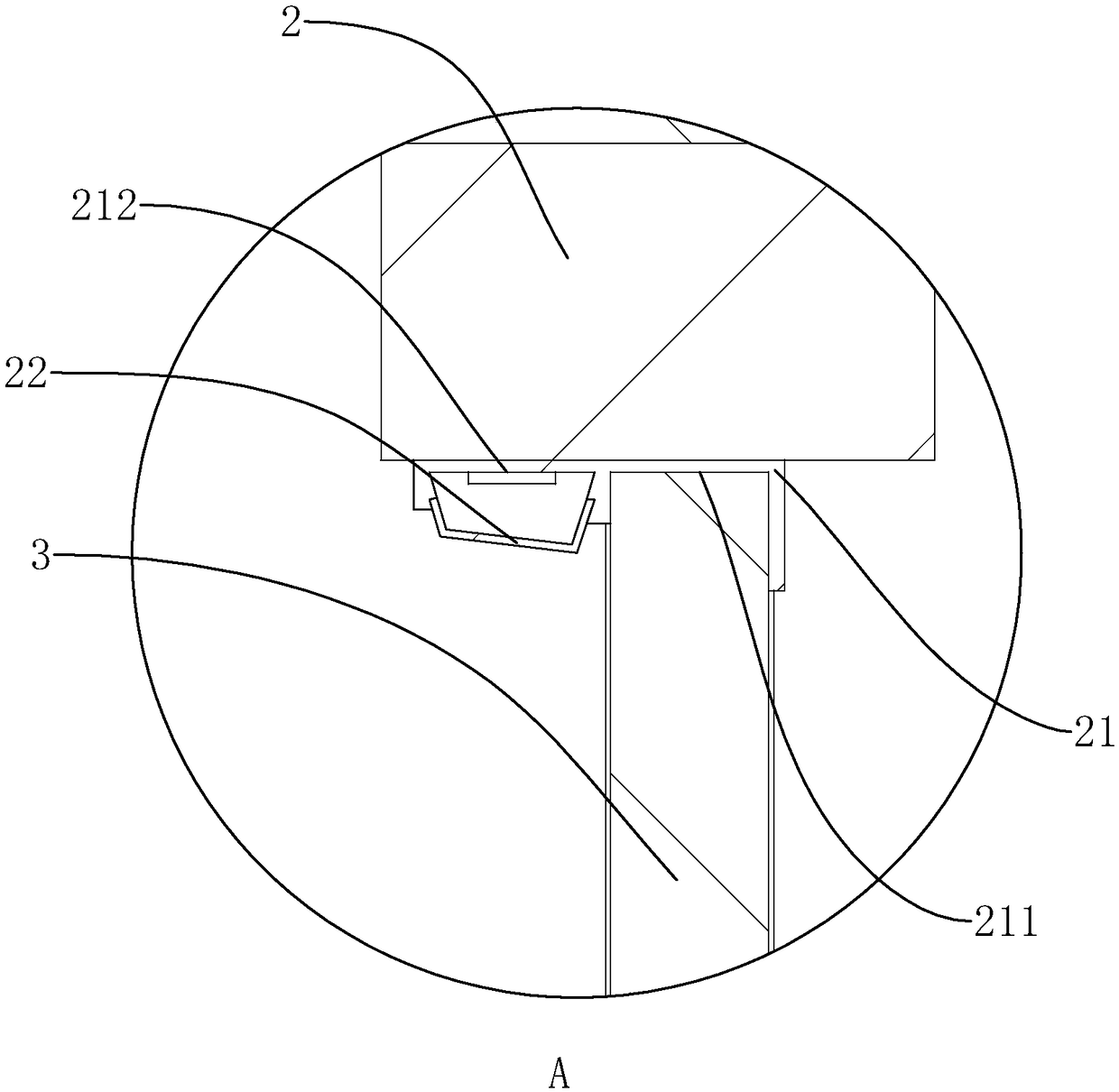

[0043] Such as figure 2 , image 3 As shown, the lower side of the upper pole 2 is fixedly connected with an upper connecting bar 21 , a plurality of glass walls 3 whose upper ends are plugged into the upper connecting bars 21 , and at least one glass door 4 connected with the glass wall 3 . It should be mentioned that between two adjacent glass walls 3 and between the walls of the house frame 1 and the glass walls 3, an adhesive body 5 is arranged, and then between the house frame 1 and a plurality of glass walls 3 and the glass door body 4 form an independent inner cavity 11, and the upper strut 2 plays the role of improving the installation and fixing stability of the upper stru...

Embodiment 2

[0052] Compared with Example 1, the viscose body of Example 2 includes the following components by weight:

[0053] 26 parts of 107 silicone rubber, 12 parts of white mineral oil, 2 parts of polyvinyl butyral, 2.5 parts of γ-aminopropyltriethoxysilane, 2.5 parts of sericite, 0.75 parts of methyltrimethoxysilane, 1.5 parts White carbon black, 1.5 parts of calcium carbonate, 0.05 parts of dibutyltin dilaurate and 0.05 parts of butanone oxime;

[0054] The preparation method of viscose comprises the steps:

[0055] Step 1: Put 2.5 parts of sericite, 1.5 parts of white carbon black, 1.5 parts of calcium carbonate, 0.05 parts of dibutyltin dilaurate and 0.05 parts of butanone oxime into reaction kettle A with a temperature of 76°C and a vacuum of 0.3 MPa Stir for 1h to obtain mixed material A;

[0056] Step 2: Put 26 parts of 107 silicone rubber, 12 parts of white mineral oil, 0.75 parts of methyltrimethoxysilane, 2.5 parts of γ-aminopropyltriethoxysilane and 2 parts of polyvinyl...

Embodiment 3

[0059] Compared with Example 1, the viscose body of Example 3 includes the following components by weight:

[0060] 27 parts of 107 silicone rubber, 13 parts of white mineral oil, 2 parts of polyvinyl butyral, 2.5 parts of γ-aminopropyltriethoxysilane, 2.5 parts of sericite, 0.75 parts of methyltrimethoxysilane, 1.5 parts White carbon black, 1.5 parts of calcium carbonate, 0.05 parts of dibutyltin dilaurate and 0.05 parts of butanone oxime;

[0061] The preparation method of viscose comprises the steps:

[0062] Step 1: Put 2.5 parts of sericite, 1.5 parts of white carbon black, 1.5 parts of calcium carbonate, 0.05 parts of dibutyltin dilaurate and 0.05 parts of butanone oxime into reaction kettle A with a temperature of 74°C and a vacuum of 0.3 MPa Stir for 1h to obtain mixed material A;

[0063] Step 2: Put 27 parts of 107 silicone rubber, 13 parts of white mineral oil, 0.75 parts of methyltrimethoxysilane, 2.5 parts of γ-aminopropyltriethoxysilane and 2 parts of polyvinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com