Biomass fuel combustion and gasification integrated furnace for flue-cured tobacco

A biomass fuel and combustion-supporting gas technology, which is used in the combustion of solid fuel, controlled combustion, combustion equipment, etc., can solve the problem of not specifying the structure of the furnace body and the combustion principle, accelerating the aging of the steel heat pipe, and the easy accumulation of flying dust for heat dissipation. and other problems, to achieve the effect of green baking benefits and increasing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

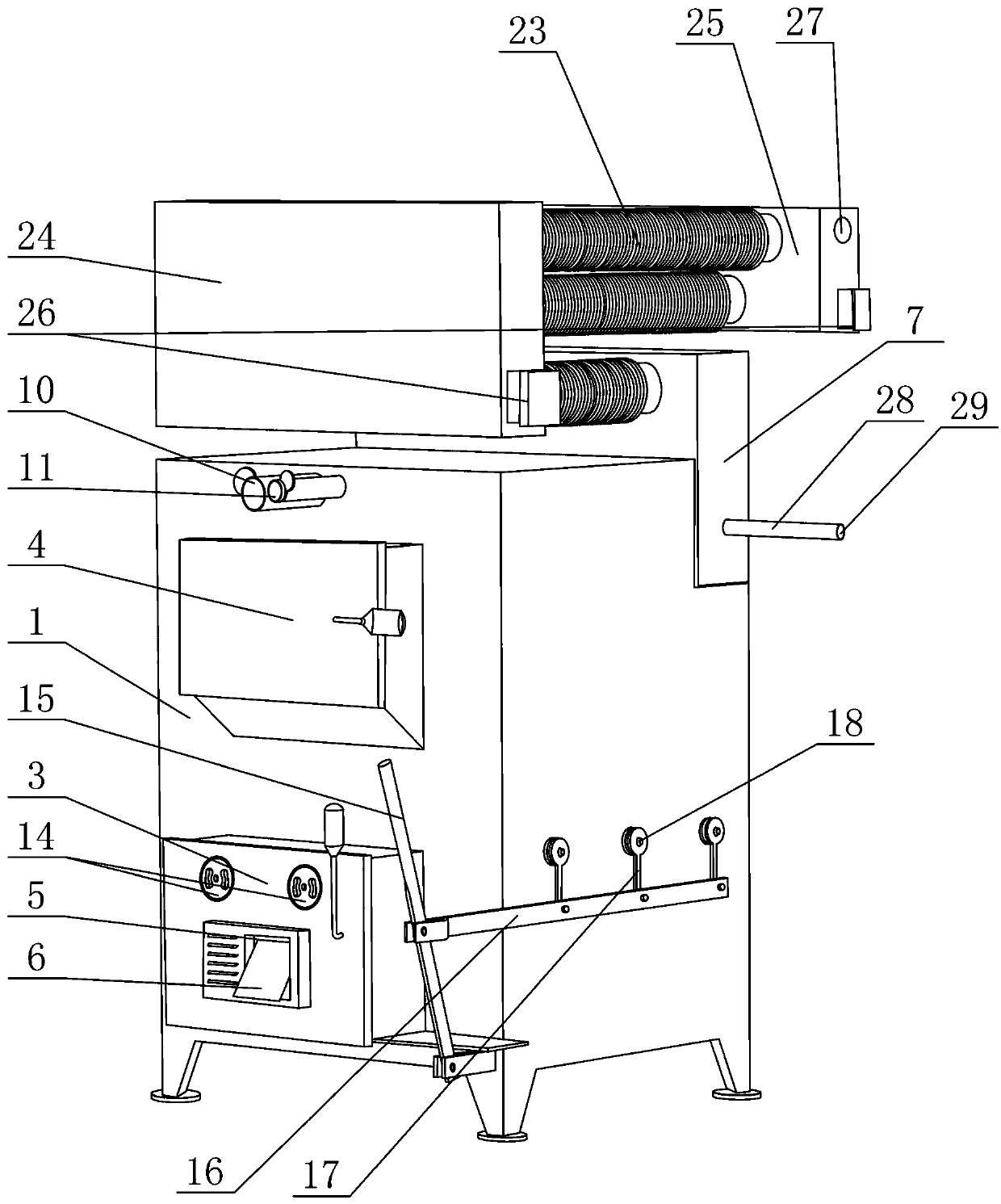

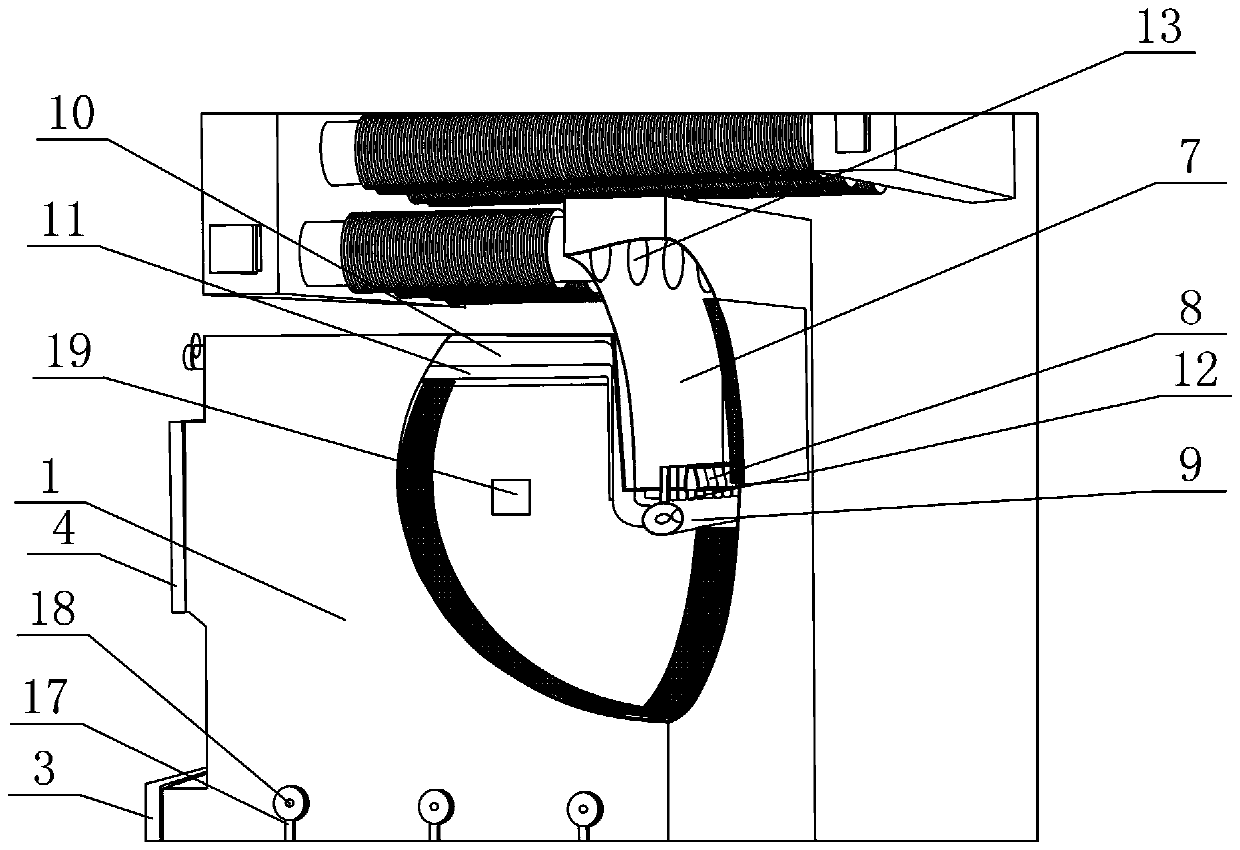

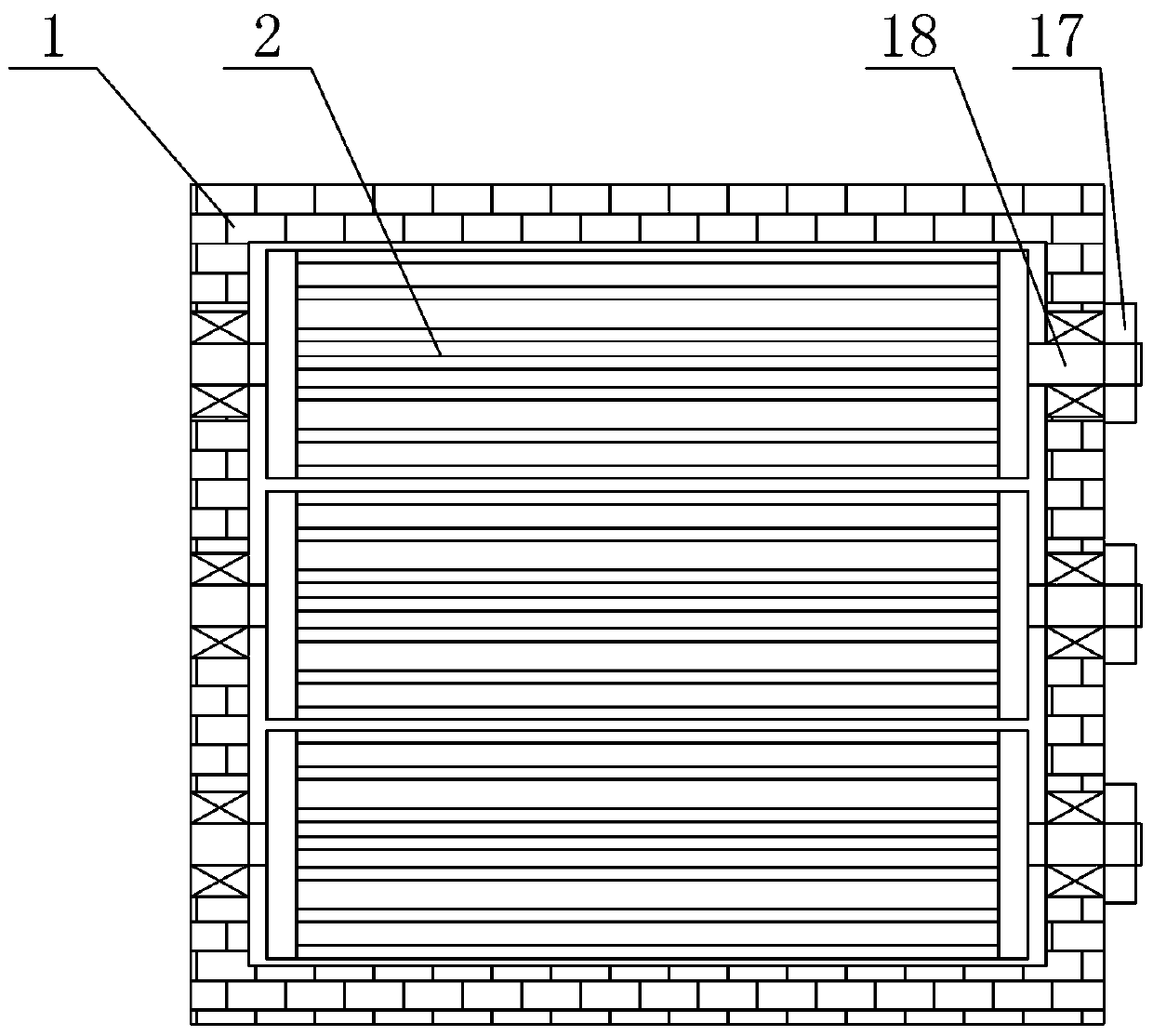

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, a biomass fuel combustion and gasification integrated furnace for flue-cured tobacco includes a fuel combustion gasification device, a gas combustion device and a heat dissipation device. The fuel combustion gasification device includes a furnace body 1, a grate 2, and a soot cleaning port , soot removal furnace door 3, fuel addition port, fuel addition door 4, air inlet 5, air intake gate 6 and ash removal device, the furnace body 1 is provided with a fire grate 2, and the fire grate 2 rotates relative to the furnace body 1 connected, the outside of the furnace body 1 is provided with a soot cleaning device, and the soot cleaning device drives the grate 2 to rotate relative to the furnace body 1, and the grate 2 divides the inner cavity of the furnace body 1 into upper and lower parts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com