Deep ultraviolet narrow band filter

A narrow-band filter and filter technology, applied in the direction of optical filters, optics, optical components, etc., can solve the problems of low short-wave transmittance, low peak transmittance, and difficult filter cut-off, so as to reduce reflected light , reduce the bandwidth, improve the effect of transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

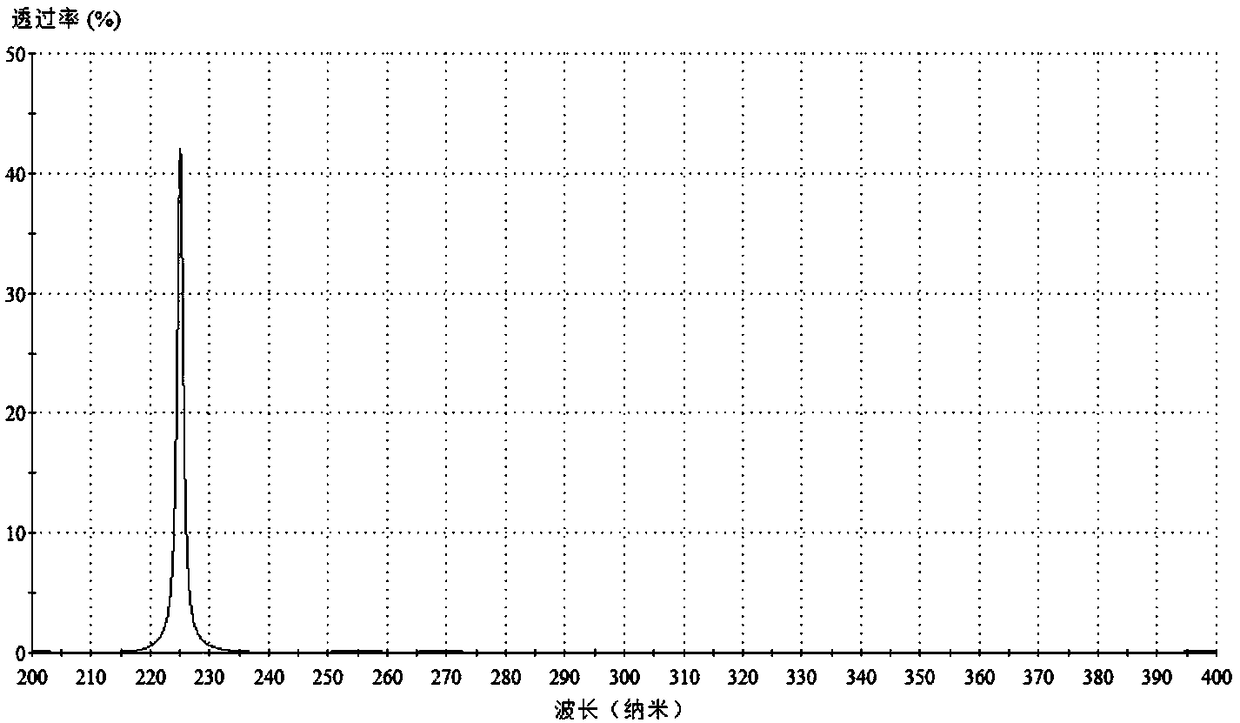

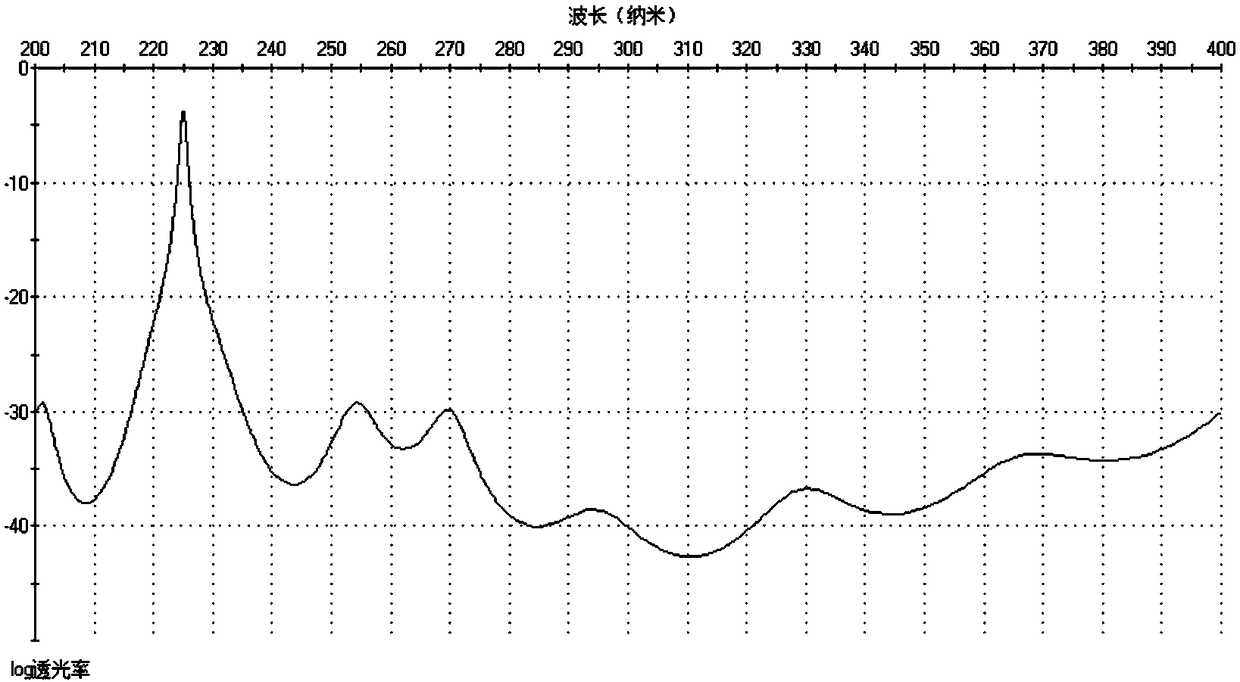

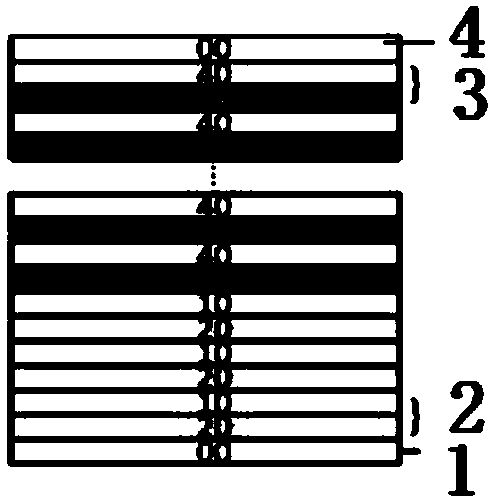

[0068] The main structure of the deep ultraviolet narrow-band filter involved in this embodiment includes a base layer 1, a filter layer 2, a film layer 3 and a protective layer 4; the upper surface of the base layer 1 is deposited with 3 layers of filter layers 2, and finally The upper surface of the upper filter layer 2 is deposited with 13 film layers 3; the base layer 1 is JGS1; the main structure of the filter layer 2 includes the filter layer spacer layer 10 and the reflective layer 20, and the upper surface of the reflective layer Deposit the filter layer spacer layer 10, the filter layer spacer layer 10 is SiO 2 , the reflective layer 20 is Al, and the filter layer 2 is a double half-wave F-P interference filter structure (Al / SiO 2 / Al / SiO 2 / Al / SiO 2 ), metal Al has a large extinction coefficient and high reflection characteristics in the visible light band, Al and SiO 2 The combination can realize the depth cut-off of specific waveband and the high transmittance i...

Embodiment 2

[0072] The preparation process of the deep ultraviolet narrow-band filter involved in this embodiment includes five steps: designing the film system formula, preparing the base layer, preparing the filter layer, preparing the film layer and controlling the thickness of the film layer:

[0073] (1) Design film system formula: JGS1, Al, SiO selected according to Example 1 2 、 Al 2 o 3 and MgF 2 The technical requirements of the refractive index, extinction coefficient and bandwidth of less than 2nm are designed to design a film system formula: SiO 2 |HMH H2MH(MH)^2M(HM)^2H2MH(MH)^2 (NL)^3|JGS1, where L is Al and H is Al 2 o 3 , M is MgF 2 , N is SiO 2 , use Essential Macleod (optical thin film analysis and design software) or TFCalc (thin film design software) to simulate, optimize and change the physical thickness value of the film system formula;

[0074] (2) Preparation of base layer: cutting JGS1 into base layer 1 according to the set size;

[0075] (3) Prepare the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com