Preparation method of semimetal phase molybdenum telluride based on mild hydrogen plasma

A plasma and semi-metal technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of sample structure damage, difficulty in obtaining uniform phase transition, poor operability, etc., and achieve uniform phase transition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

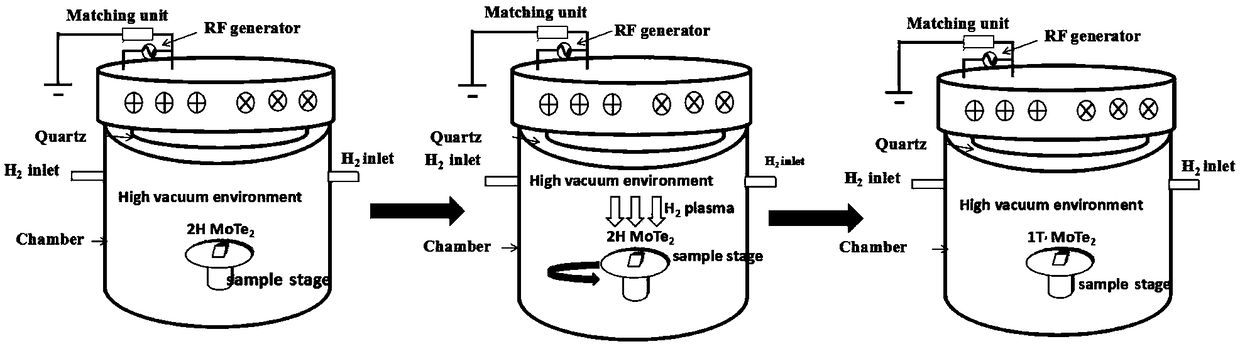

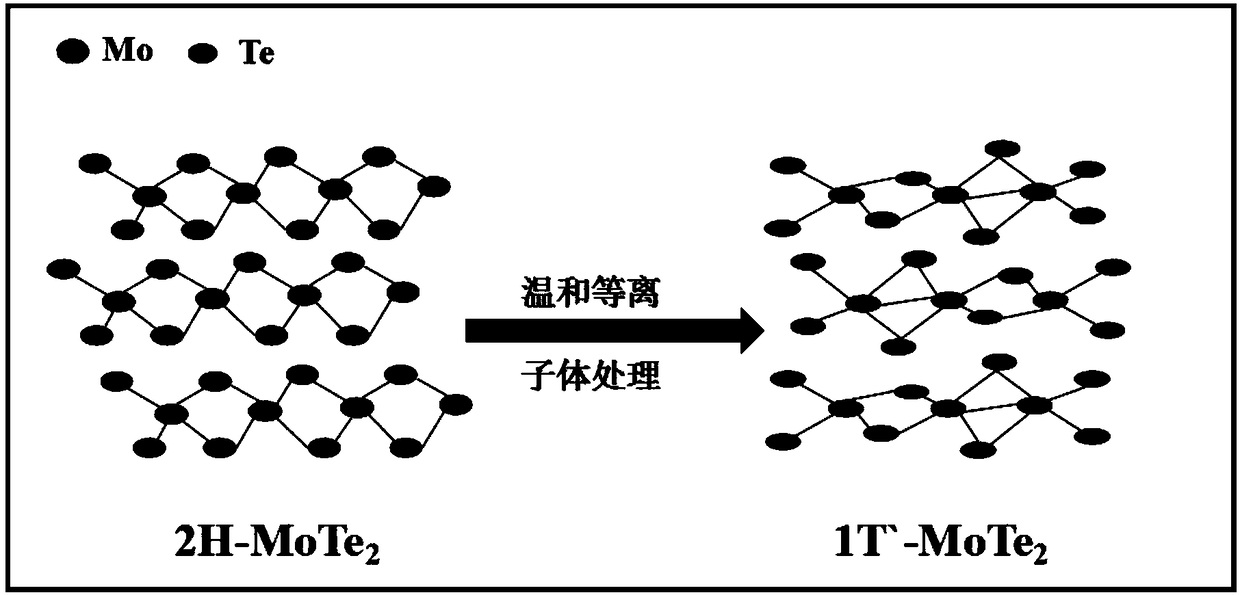

[0027] see figure 1 and figure 2 , a method for preparing semi-metallic molybdenum telluride based on mild hydrogen plasma, comprising the following steps:

[0028] (1) Substrate cleaning: In this embodiment, a silicon wafer plated with a 300nm silicon dioxide layer is used as a substrate, and the substrate is respectively placed in acetone, ethanol, and deionized water for ultrasonic cleaning for 5 minutes each to remove surface organic matter. The ultrasonic frequency is 25KHz. Then bake on a heating platform at 350°C for 30 minutes to remove residues such as acetone and ethanol.

[0029] (2) Sample preparation: In this example, the semiconductor phase MoTe prepared by mechanical exfoliation 2 TLC. Using plastic film for MoTe 2 The block is peeled off, and then the adhesive films are torn apart until the color of the sample on the adhesive film is grayish, and then pasted on the cleaned substrate and pressed gently. After standing for 1 hour, quickly peel off the film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com