Manufacturing method of semiconductor element and manufacturing method of solar cell

A manufacturing method and semiconductor technology, which are applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of increasing the number of steps, and achieve the effect of reducing the number of steps and suppressing out-diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] Into a 500mL three-necked flask, 20.8g of polyvinyl alcohol (manufactured by Wako Pure Chemical Industries, the degree of polymerization is 500) and 144g of water were dropped into, and the temperature was raised to 80°C while stirring, and after stirring for 1 hour, propylene glycol monomethyl ether ( KH Neochem Co., Ltd.) 231.6 g and 3.6 g of diboron trioxide were stirred at 80° C. for 1 hour. After cooling to 40° C., 0.12 g of a fluorine-based surfactant MEGAFACE F477 (manufactured by DIC Corporation) was added and stirred for 30 minutes to prepare a p-type impurity diffusion composition.

[0122] Next, on one surface of the n-type semiconductor substrate textured on both surfaces, the p-type impurity diffusion composition was coated on the entire surface by spin coating, and dried at 150° C. for 1 minute to produce a pattern formed on one surface. A semiconductor substrate having a p-type impurity diffusion composition film.

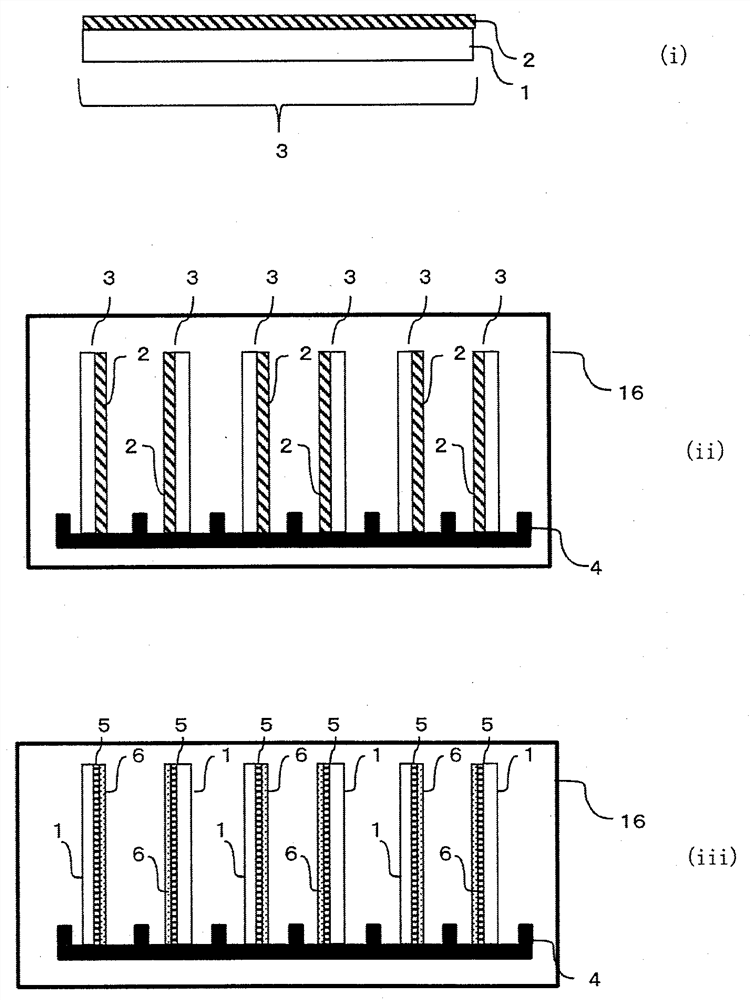

[0123] Next, if figure 1 As shown in ...

Embodiment 2

[0130] On one surface of an n-type semiconductor substrate textured on both surfaces, the same p-type impurity diffusion composition as in Example 1 was coated on the entire surface by spin coating, and dried at 150° C. for 1 minute to fabricate A semiconductor substrate having a p-type impurity diffusion composition film formed on one surface.

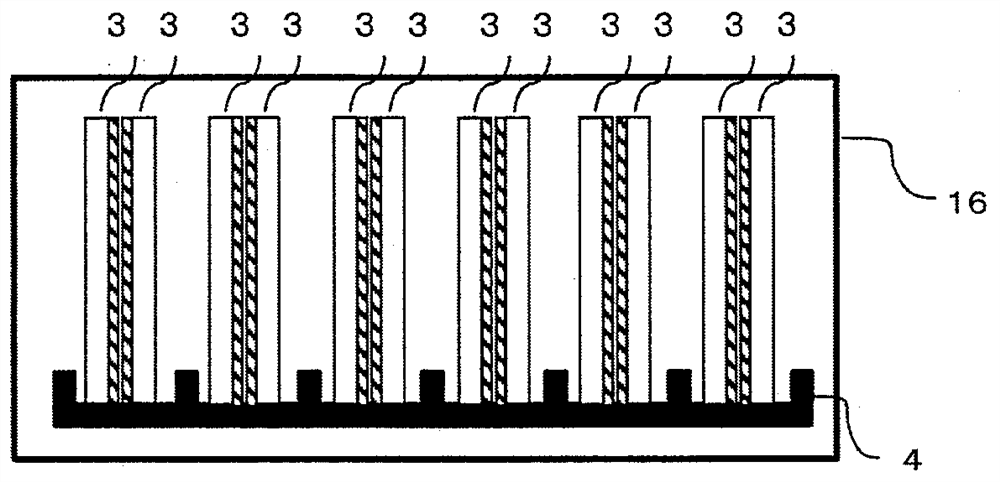

[0131] Next, if figure 2 As shown, a semiconductor substrate having a p-type impurity diffusion composition film formed on one surface is disposed on the diffusion plate. The distance between the surfaces on which the p-type impurity-diffusion composition film was formed was 0 mm, and the distance between the surfaces on which the p-type impurity-diffusion composition film was not formed was 3 mm in a pair of semiconductor substrates.

[0132] Next, in circulation O 2 : 0.2L / min, N 2 : In a 9.8 L / min diffusion furnace (Koyo Thermo Systems Co., Ltd., 206A-M100), a diffusion plate was placed in a state set at 700°C. Thereafter, the...

Embodiment 3

[0138] On one surface of an n-type semiconductor substrate textured on both surfaces, the same p-type impurity diffusion composition as in Example 1 was coated on the entire surface by spin coating, and dried at 150° C. for 1 minute to fabricate A semiconductor substrate having a p-type impurity diffusion composition film formed on one surface.

[0139] Next, if figure 2As shown, a semiconductor substrate having a p-type impurity diffusion composition film formed on one surface is disposed on the diffusion plate. The distance between the surfaces on which the p-type impurity-diffusion composition film was formed was 0 mm, and the distance between the surfaces on which the p-type impurity-diffusion composition film was not formed was 3 mm in a pair of semiconductor substrates.

[0140] Next, in circulation O 2 : 0.2L / min, N 2 : In a 9.8 L / min diffusion furnace (Koyo Thermo Systems Co., Ltd., 206A-M100), a diffusion plate was placed in a state set at 700°C. Thereafter, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com