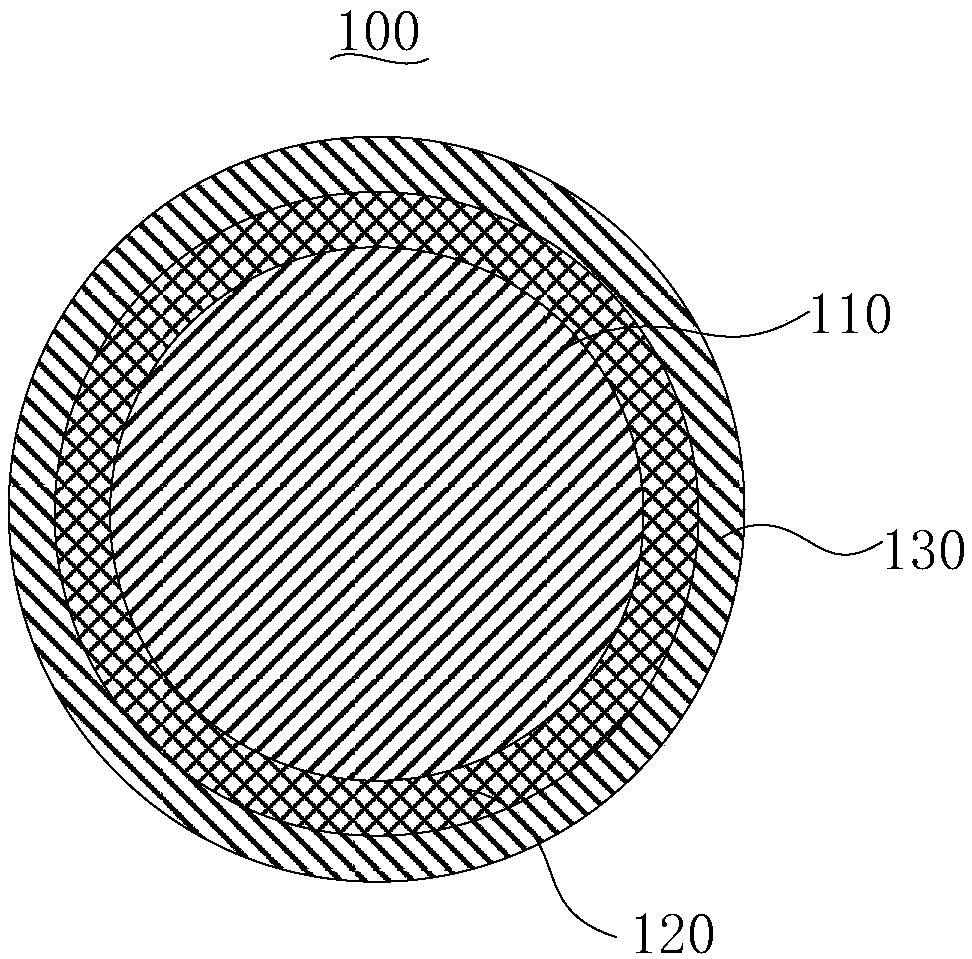

Essence microcapsule and preparation method and application thereof

A technology of essence microcapsules and capsule cores, applied in the field of essences and fragrances, can solve the problems of weak explosiveness, volatile, insufficient aroma intensity, etc., and achieve the effects of prolonging release time, good aroma explosiveness, and strong aroma intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

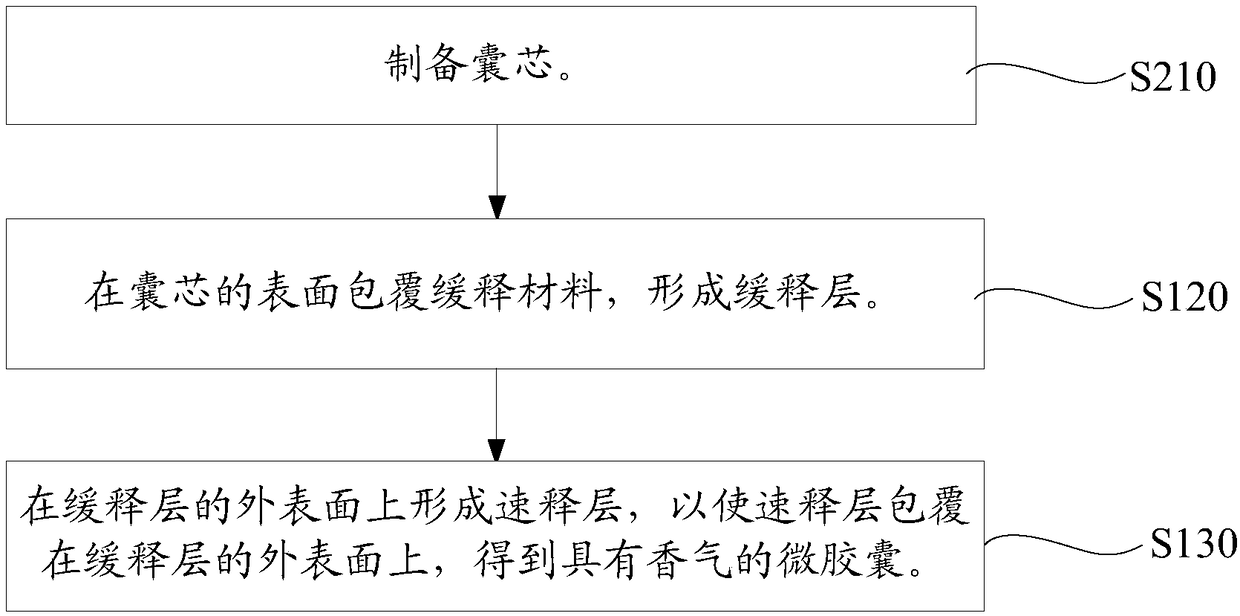

[0062] Such as figure 2 As shown, the preparation method of the essence microcapsule 100 in one embodiment is a preparation method of the above-mentioned essence microcapsule 100, and the method includes the following steps:

[0063] Step S210: Prepare the capsule core 110.

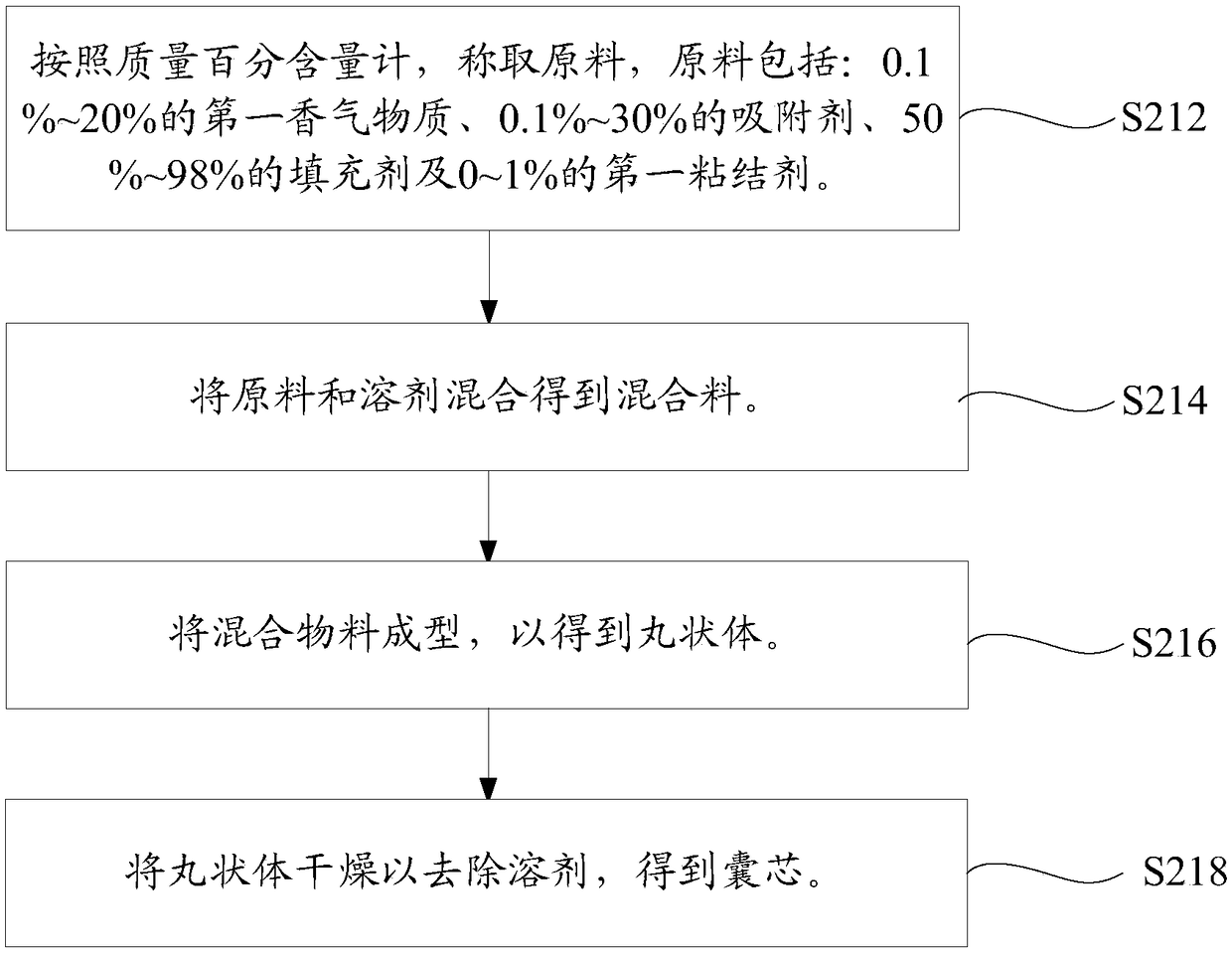

[0064] Please also refer to image 3 , specifically, the steps for preparing the capsule core 110 are as follows:

[0065] Step S212: Weigh the raw materials according to the mass percentage, the raw materials include: 0.1%-20% of the first aroma substance, 0.1%-30% of the adsorbent, 50%-98% of the filler and 0-1% the first binder.

[0066] The first aroma substance is selected from at least one of essence, fragrance and plant extract. Among them, the fragrance is selected from mint flavor essence, fruit flavor essence, flower fragrance essence, milk flavor essence, coffee flavor essence, chocolate flavor essence, nut flavor essence, baking flavor essence and green fragrance essence , one of grass-f...

Embodiment 1~10

[0101] The preparation process of the essence microcapsules of embodiment 1~10 is as follows:

[0102] (1) Preparation of the capsule core: according to the mass percentage, weigh the raw material of the capsule core according to Table 1; mix the first aroma substance and the adsorbent so that the first aroma substance is adsorbed into the adsorbent, and then add the filling agent and the first binder, and mix uniformly to obtain a mixture; stir and mix the mixture with water to obtain a mixture; use extrusion spheronization equipment to prepare the mixture into pellets, and dry the pellets at 50°C to The water in the pellet is removed to obtain the capsule core.

[0103] (2) dissolving the sustained-release material in water to obtain a slurry with a concentration of 10% by mass; coating the slurry on the surface of the capsule core by using a coating machine to form a sustained-release layer on the surface of the capsule core. Wherein, the weight of the slow-release layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com