Method for mixing raw materials for fumed white carbon black production

A technology of fumed white carbon black and raw materials, applied in chemical instruments and methods, climate sustainability, silicon compounds, etc., can solve the problems of difficult production control, affecting heat exchange effect, high operating costs, etc., to achieve easy disassembly and cleaning, Good economic benefits and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

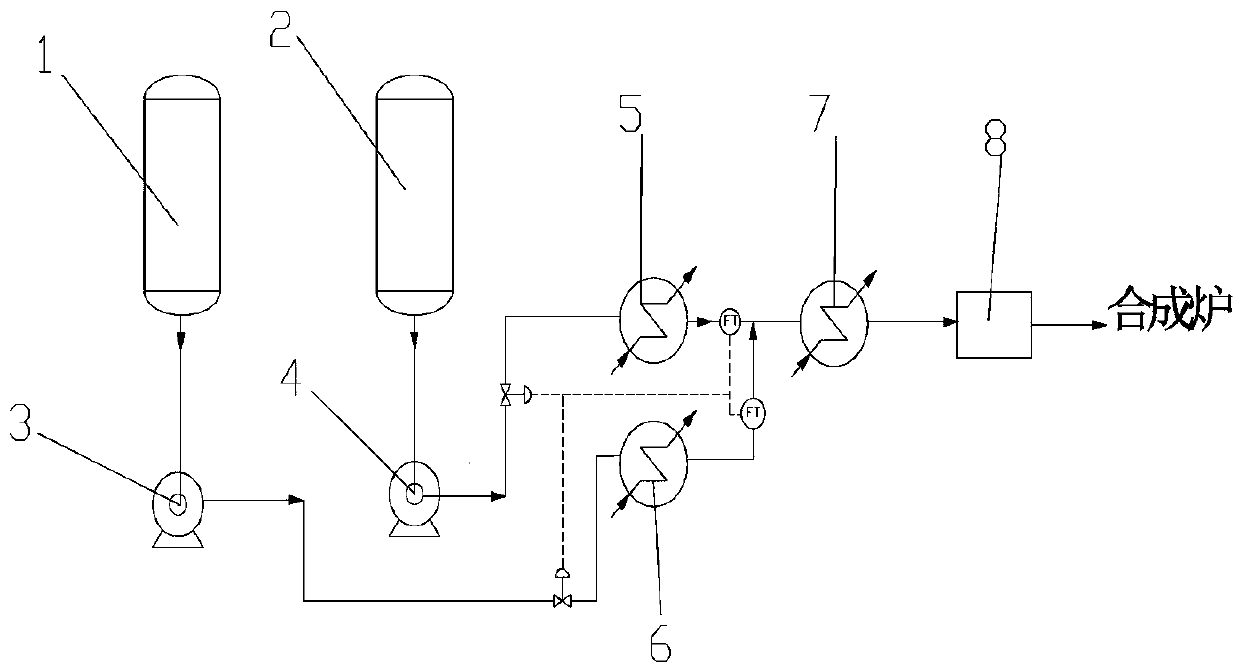

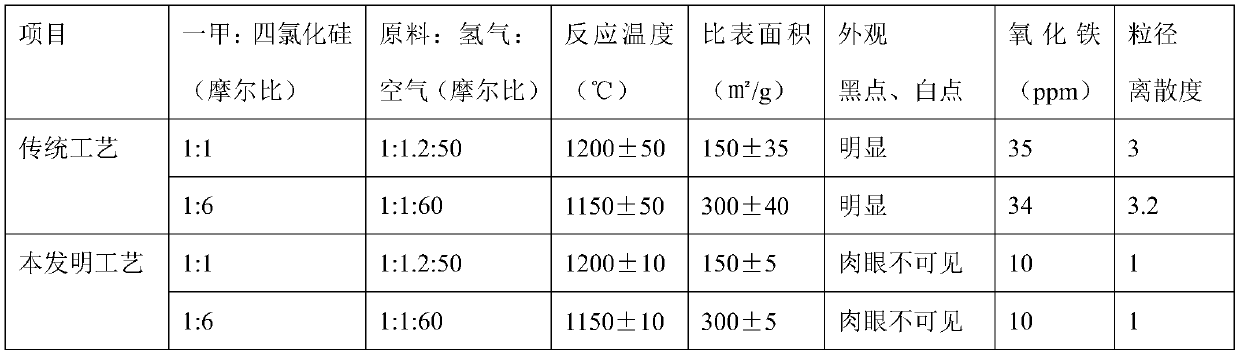

[0014] The flow rate of monomethyltrichlorosilane is adjusted to 1 t / h by the regulating valve, and it is injected into the monomethyltrichlorosilane vaporizer (6) by the monomethyltrichlorosilane feed pump (3) to be vaporized at a temperature of 68°C. The silicon tetrachloride controlled flow rate of 1.137t / h is pumped into the silicon tetrachloride vaporizer (5) by the silicon tetrachloride feed pump (4), and the vaporization temperature is 60°C. The silicon tetrachloride vaporizer (5) and the monomethyltrichlorosilane vaporizer (6) are heated by 0.2MPa (G) steam. The two vaporized gases are mixed in the pipeline and then enter the superheater (7). The superheater is heated by 1.0MPa(G) steam, the superheating temperature is 160°C, and the pressure is 0.08MPa(G). The distance L between the contact point of silicon chloride in the pipeline and the superheater is 2.5m. The mixing contact time of monomethyltrichlorosilane and silicon tetrachloride is 4s. After the superheated...

Embodiment 2

[0016] The monomethyltrichlorosilane flow rate in the monomethyltrichlorosilane storage tank (1) is 1t / h and is pumped (3) into the vaporizer (6) for vaporization, and the vaporization temperature is 68°C; the silicon tetrachloride The flow of silicon tetrachloride and monomethyltrichlorosilane in the storage tank (2) is adjusted in cascade to control the flow rate of 2.274t / h, which is injected into the vaporizer (5) by the pump (4) for vaporization, and the vaporization temperature is 60°C; Methyltrichlorosilane and silicon tetrachloride are mixed in the pipeline and enter the superheater (7), the superheating temperature is 160°C, and the pressure is 0.08MPa(G). The distance L between the vaporized monomethanol and silicon tetrachloride in the pipeline from the contact point to the superheater is 3m. The mixing contact time of monomethyltrichlorosilane and silicon tetrachloride is 7s. The mixed gas from the superheater is filtered by the precision filter (8), mixed with hy...

Embodiment 3

[0018] The flow of monomethyltrichlorosilane in the monomethyltrichlorosilane storage tank (1) is 1.5t / h and is pumped (3) into the vaporizer (6) for vaporization, and the vaporization temperature is 80°C; The silicon tetrachloride in the silicon storage tank (2) and the monomethyl trichloride in the silicon storage tank (2) are cascaded to adjust the control flow rate of 0.853t / h by the pump (4) into the vaporizer (5) for vaporization, and the vaporization temperature is 90°C; the vaporized monomethyl trichloride Chlorosilane and silicon tetrachloride are mixed in the pipeline and enter the superheater (7), with a superheating temperature of 170°C and a pressure of 0.12MPa(G). The mixed gas from the superheater is filtered by the precision filter (8), mixed with hydrogen and air in a molar ratio of 1:1.2:10, and sent to the synthesis furnace to be hydrolyzed at 1260°C to generate gas-phase white carbon black.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com