Method for cultivating saline and alkaline land by utilizing garbage of meat processing factory

A technology of combining meat factory and saline-alkali land, applied in the field of saline-alkali land conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1 Garbage disposal in meat processing plants

[0046] The drained cooked meat was chopped into meat strips with a length of 1.7 cm; the hair in the garbage was soaked in an aqueous solution of keratinase, and enzymatically hydrolyzed at 50° C. for 2.4 hours.

[0047] Step 2 prepare the maintenance agent

[0048] Then mix the mixture 1 with the mixed starter in a mass ratio of 100:4; after mixing evenly, put it in a fermenter, and ferment in a sealed manner at 29°C for 9 days.

[0049] Step 3 Conservation of saline-alkali land

[0050] The plowing depth is 5cm; the application rate of the conservation agent is 72kg / mu.

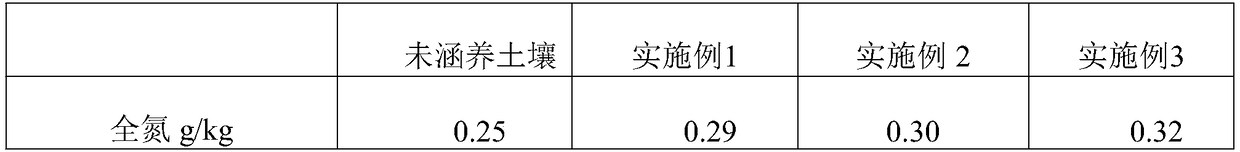

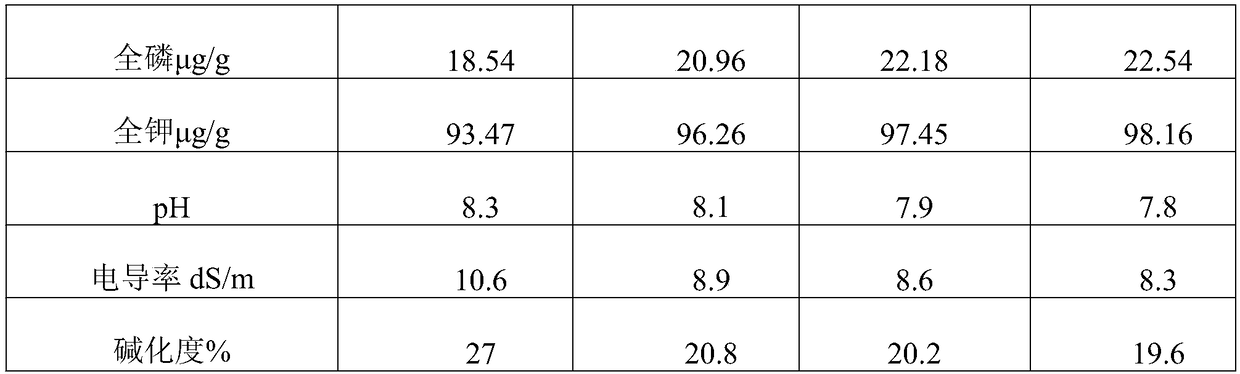

[0051] After the saline-alkali land is conserved by the above method, the total nitrogen content of the saline-alkali land is 0.29g / kg; the total phosphorus content is 20.96 μg / g; the total potassium content is 96.26 μg / g; the pH is reduced to 7.8; ; Alkalinity decreased to 20.8%.

Embodiment 2

[0053] Step 1 Garbage disposal in meat processing plants

[0054] The drained cooked meat was chopped into meat strips with a length of 1.8 cm; the hair in the garbage was soaked in an aqueous solution of keratinase, and enzymatically hydrolyzed at 55° C. for 2.5 hours.

[0055] Step 2 prepare the maintenance agent

[0056] Then mix the mixture one with the mixed starter in a mass ratio of 100:3; after mixing evenly, put it in a fermenter, and ferment in a sealed condition at 30°C for 10 days.

[0057] Step 3 Conservation of saline-alkali land

[0058] The plowing depth is 3cm; the application rate of the conservation agent is 68kg / mu.

[0059] After the saline-alkali land is conserved by the above method, the total nitrogen content of the saline-alkali land is 0.30g / kg; the total phosphorus content is 22.18 μg / g; the total potassium content is 97.45 μg / g; the pH is reduced to 7.7; ; Alkalinity decreased to 20.2%.

Embodiment 3

[0061] Step 1 Garbage disposal in meat processing plants

[0062] The drained cooked meat was chopped into 2 cm long meat strips; the hair in the garbage was soaked in an aqueous keratinase solution, and enzymatically hydrolyzed at 52°C for 2.6 hours.

[0063] Step 2 prepare the maintenance agent

[0064] Then mix the mixture one with the mixed starter in a mass ratio of 100:5; after mixing evenly, put it in a fermenter, and ferment for 9 days in a sealed condition at 32°C.

[0065] Step 3 Conservation of saline-alkali land

[0066] The plowing depth is 4cm; the application rate of the conservation agent is 73kg / mu.

[0067] After the saline-alkali land is conserved by the above method, the total nitrogen content of the saline-alkali land is 0.32g / kg; the total phosphorus content is 22.54μg / g; the total potassium content is 98.16μg / g; the pH is reduced to 7.5; ; Alkalinity decreased to 19.6%.

[0068] The data of each index of described saline-alkali land soil is shown in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dilution degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com