Pre-enrichment heavy liquid for extracting aluminum, lithium and gallium from fly ash and pretreatment method

A fly ash and pretreatment technology, which is applied in the field of heavy liquid for pretreatment and pretreatment, can solve the problems of undiscovered separation medium, difficult separation and recovery, environmental pollution, inaccurate density of heavy liquid, etc., so as to reduce production cost and reasonable Allocate resources and improve the effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

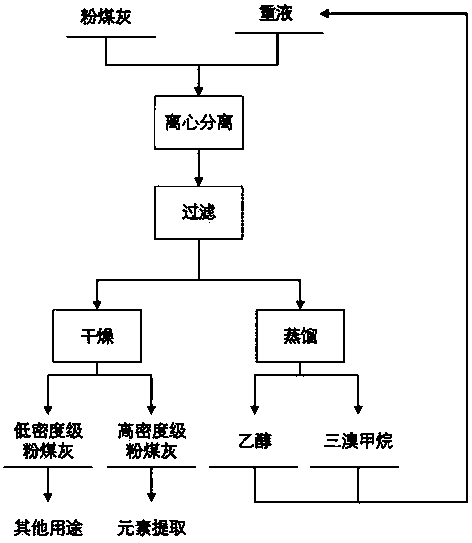

Method used

Image

Examples

Embodiment 1

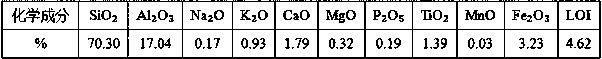

[0029] The raw material is fly ash produced in the Xishan area of Taiyuan City, Shanxi Province, and its chemical composition is shown in Table 1:

[0030] Table 1 Chemical composition list of Example 1

[0031]

[0032] 1) Prepare tribromomethane and ethanol according to the volume ratio of 2.04 to prepare a density of 2.4 g / cm 3 Add 100 ml of heavy liquid into a centrifuge tube with a capacity of 300 ml, and then add 100 ml of completely burned fly ash into the centrifuge tube, wherein, the lithium content in the fly ash is 180.81 ug / g, and the gallium content is 30.66 ug / g.

[0033] 2) Carry out centrifugation in a centrifuge, the speed of the centrifuge is 2000 r / min, and the centrifugation time is 20 min.

[0034] 3) Filtrate the suspended solids and suspended solids obtained by centrifugation in a vacuum filter, and add ethanol solution during the filtering process to rinse the organic solvent adhering to the fly ash particles.

[0035] 4) Distill the filtered li...

Embodiment 2

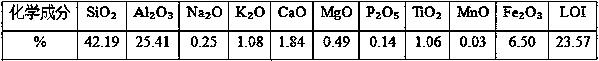

[0039] The raw material is fly ash produced by a power plant in Xishan District, Taiyuan City, Shanxi Province, and its chemical composition is shown in Table 2:

[0040] Table 2 Example 2 chemical composition list

[0041]

[0042] 1) Prepare tribromomethane and ethanol at a volume ratio of 0.92 to prepare a density of 1.8 g / cm 3 100 ml of heavy liquid is added to a centrifuge tube with a capacity of 300 ml, and then 100 ml of completely burned fly ash is added to the centrifuge tube, wherein the aluminum content in the fly ash is 112.63 ug / g, and the lithium content is 112.63 ug / g. The gallium content is 31.37 ug / g.

[0043] 2) Carry out centrifugation in a centrifuge, the speed of the centrifuge is 3000 r / min, and the centrifugation time is 30 min.

[0044] 3) Filtrate the suspended solids and suspended solids obtained by centrifugation in a vacuum filter, and add ethanol solution during the filtration process to wash away the organic solvent adhering to the fly ash pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com