Method for coating acidifier used in feed

An acidifying agent and coating technology, which is applied in the field of feeding acidifying agent coating, can solve problems such as poor stability, corrosion of production equipment, and high technical difficulty, and achieve simple and easy access to raw materials and auxiliary materials, no safety risks in the process, and technical difficulty low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

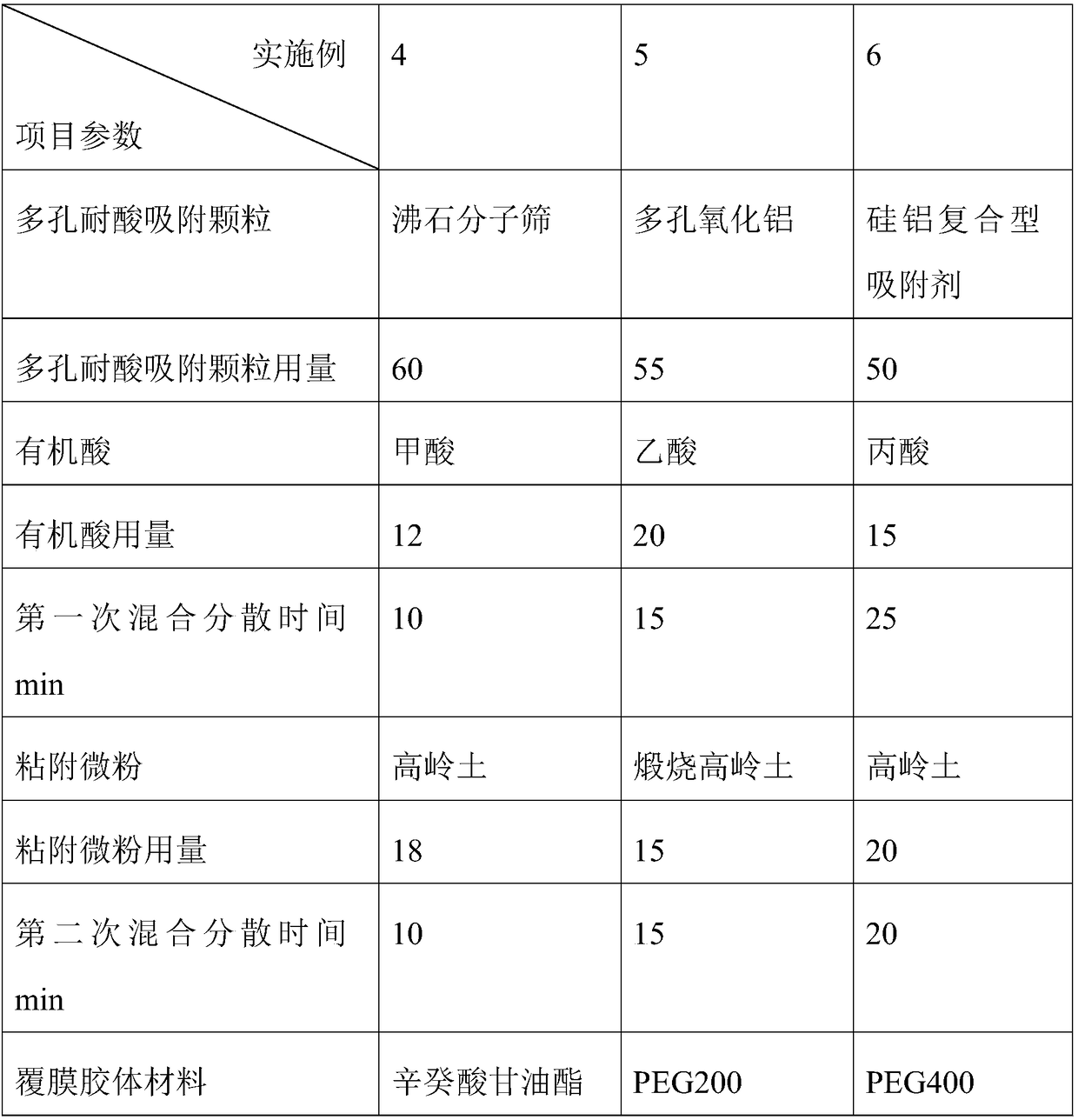

Examples

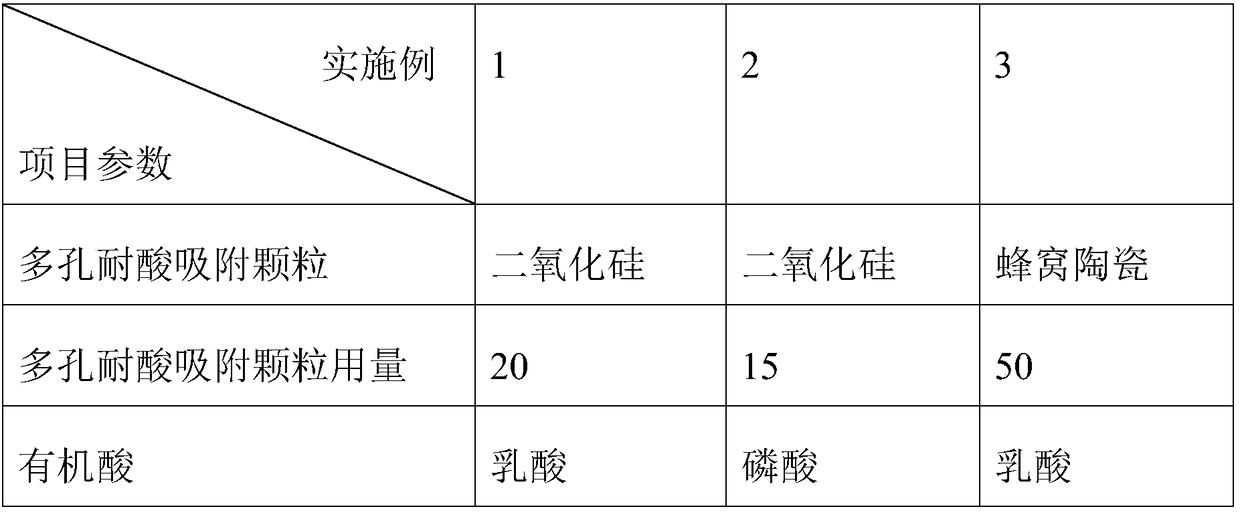

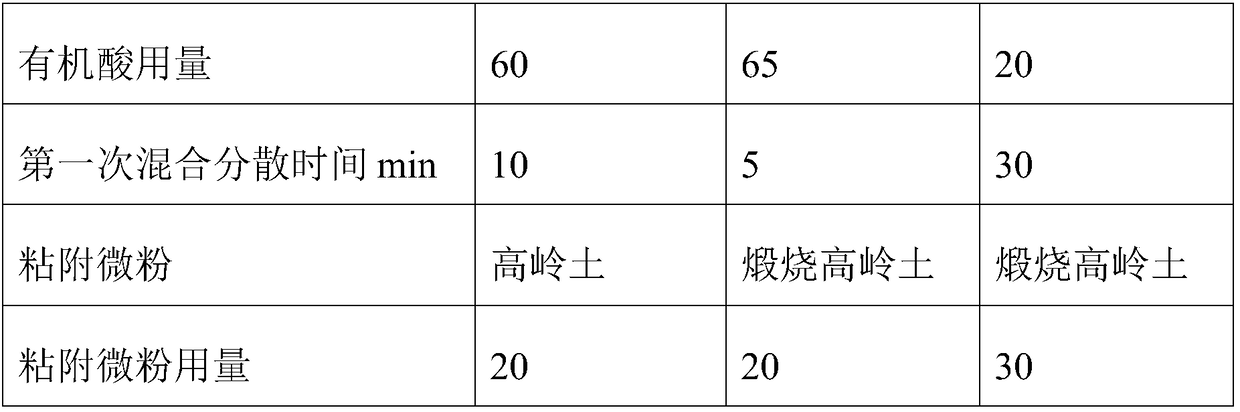

Embodiment 1

[0073] This embodiment provides a feed coating acidulant, and the coating method adopted by the feed coating acidifier is as follows:

[0074] 1. According to the parameters in Table 1, take an appropriate amount of porous acid-resistant adsorption particles with micropores, and mix and disperse them with an appropriate amount of organic acid to obtain an acidulant dispersion;

[0075] 2. Mix and disperse the acidulant dispersion with an appropriate amount of adhesive micropowder whose particle size is not larger than the micropores, make the adherent micropowder adhere to and seal the micropores, and obtain the coated acidulant for feed.

Embodiment 2

[0077] This embodiment provides a feed coating acidulant, and the coating method adopted by the feed coating acidifier is as follows:

[0078] 1. According to the parameters in Table 1, take an appropriate amount of porous acid-resistant adsorption particles with micropores, and mix and disperse them with an appropriate amount of organic acid to obtain an acidulant dispersion;

[0079] 2. Mix and disperse the acidulant dispersion with an appropriate amount of adhesive micropowder whose particle size is not larger than the micropores, make the adherent micropowder adhere to and seal the micropores, and obtain the coated acidulant for feed.

Embodiment 3

[0081] This embodiment provides a feed coating acidulant, and the coating method adopted by the feed coating acidifier is as follows:

[0082] 1. According to the parameters in Table 1, take an appropriate amount of porous acid-resistant adsorption particles with micropores, and mix and disperse them with an appropriate amount of organic acid to obtain an acidulant dispersion;

[0083] 2. Mix and disperse the acidulant dispersion with an appropriate amount of adhesive micropowder whose particle size is not larger than the micropores, make the adherent micropowder adhere to and seal the micropores, and obtain the coated acidulant for feed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com